I hone the I.D. of an old harmonic balancer to slide on the crank, so it works as a stabilizer when removing and installing tone wheels. Arus Kinney AK's Engine and Machining Covington, GA

I hone the I.D. of an old harmonic balancer to slide on the crank, so it works as a stabilizer when removing and installing tone wheels. Arus Kinney AK's Engine and Machining Covington, GA

Replace your degree wheel with a digital inclinometer. You just must make sure the one you choose has a 180° mode. Many just reset at 90°. Zero at TDC and read the angle directly. Jim Steck AutoComponenti Brookville, OH

A guy can't buy everything so when a new type of tapered bushing connecting rod comes in, I make my own installer. It's easy enough to remove the old bushing with an appropriate size bushing driver or turn one out. Remove the taper from one side of an old bushing and...

This is one that many will identify with right away. When I open a bag of valve seals, hardware, tie wraps, etc, I mark the opening cut with a sharpie. On small parts that will go flying if you're not careful, I'll use red tape. This prevents you from grabbing a...

When setting up a job on one of our milling machines, we lightly run a fine grit whetstone lightly over the milling machine’s table to make sure there are no tiny dings, lumps or bumps on the table that may cause inaccuracies when milling. The whetstone eventually...

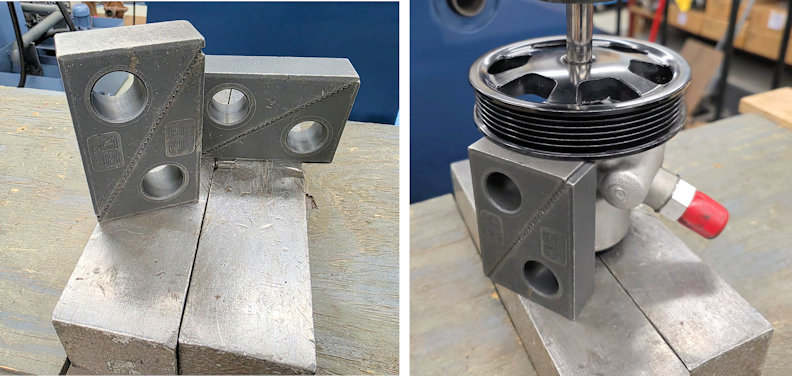

When I need some quick parallels for small jobs, I use the blocks from the Mill Clamping Set. They are adjustable for height and work well for small projects like pressing off a power steering pump pulley. Randy Torvinen Torvinen's Machine Menahga, MN