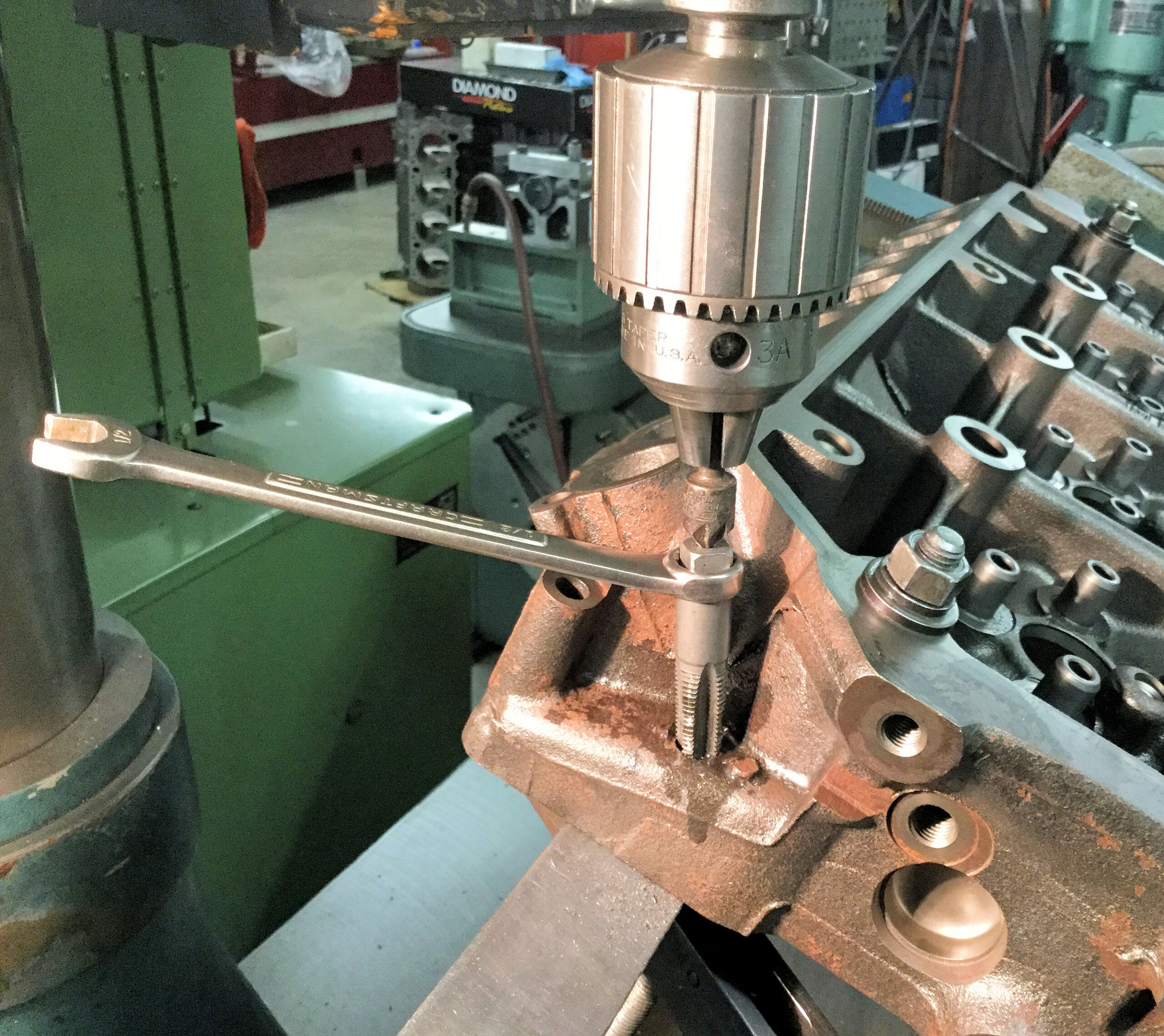

TAPPING IRREGULAR SURFACES When manually tapping on an irregular surface or where you just want it to go in dead straight to the hole you drilled, simply install an old countersink tool in the chuck after removing the drill bit. Then, drive the tap with a box end...