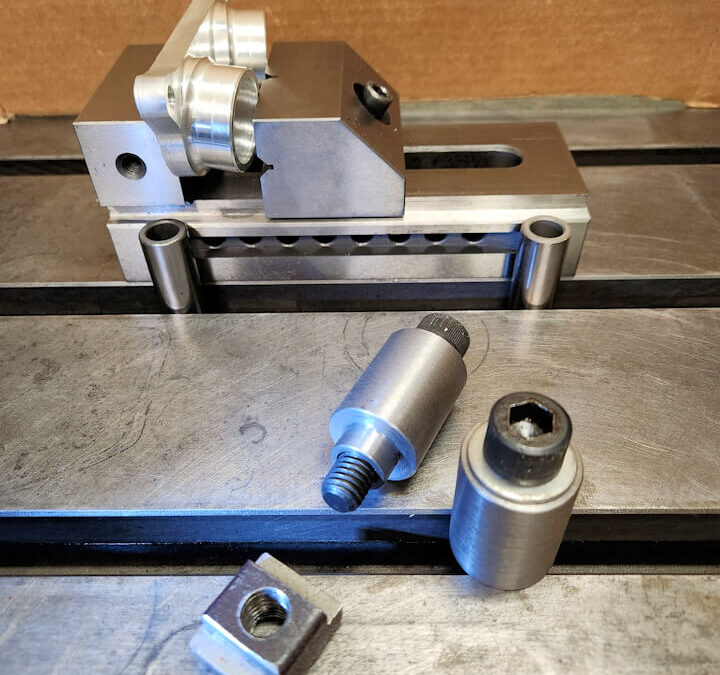

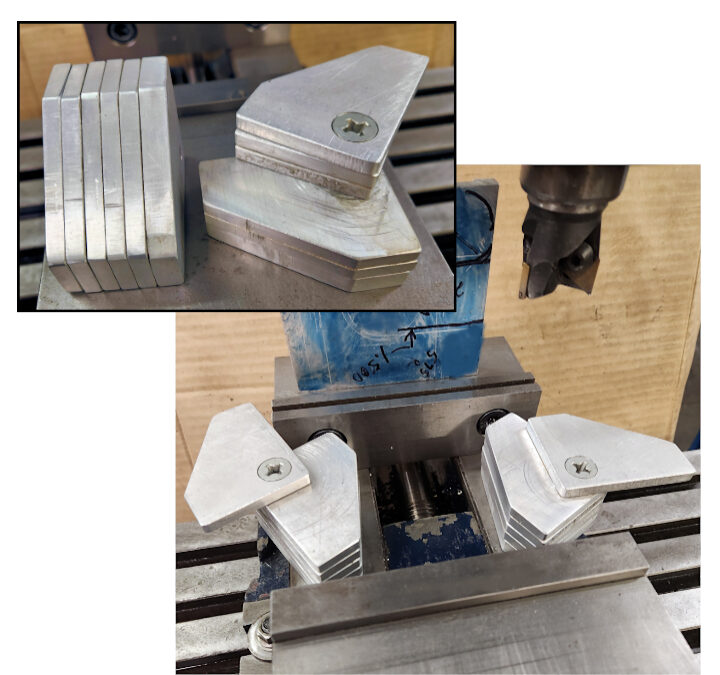

Use dowel pins or wrist pins that fit snug in your mill's T-slots to quickly tram or align a cylinder head, engine block, or vise. (shown using 18mm wrist pins). Also shown above is an alternative method. These simple to machine stepped pins, which fit snug in the...