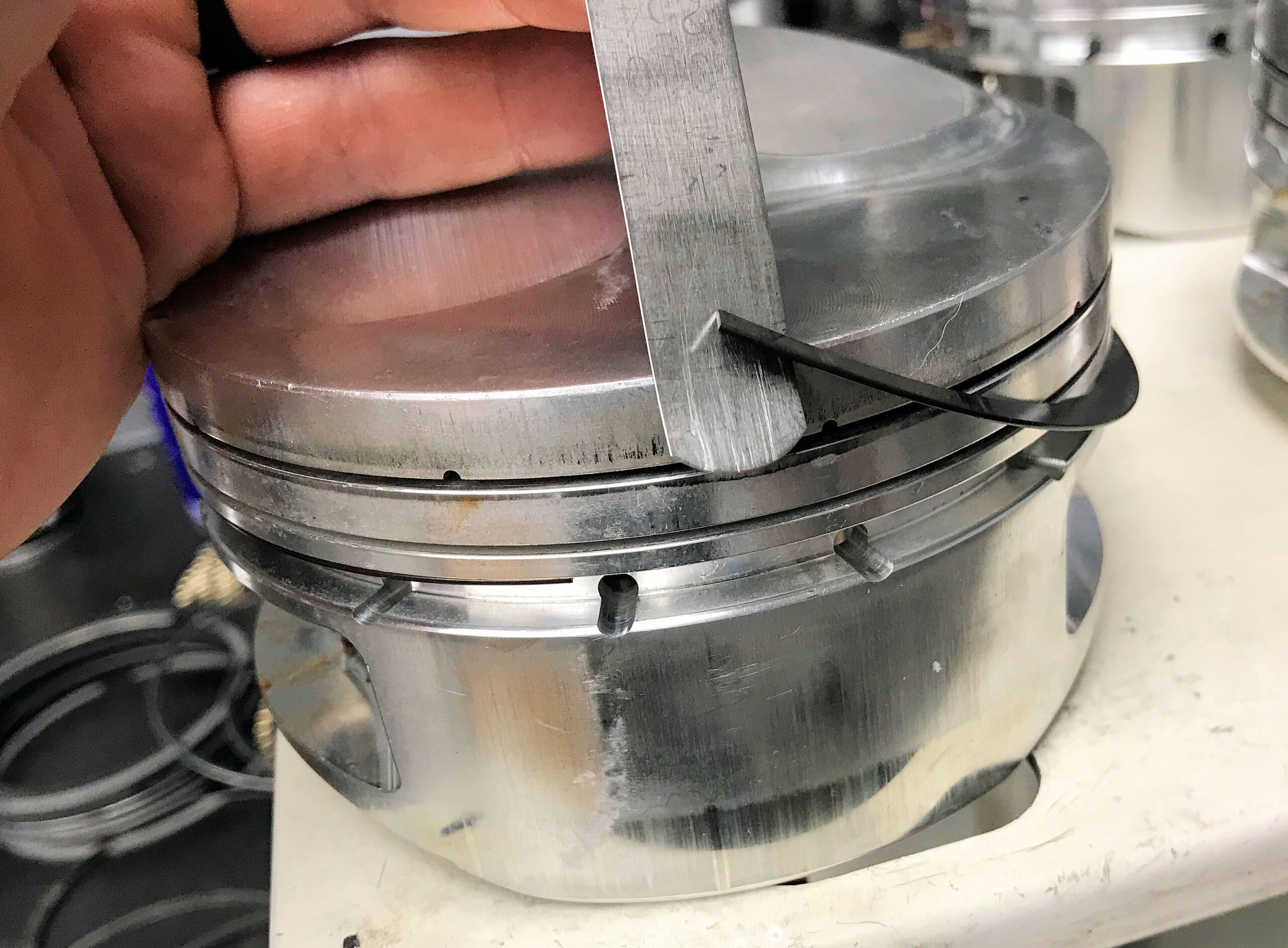

END GAP ESCAPE PATH I often feel that people will gap the top oil ring rail improperly. The top oil ring rail needs to have a gap that is the same as the 2nd (scraper) ring above it, at operating temp. Gapping it the same is a safe adjustment. The tapered second...