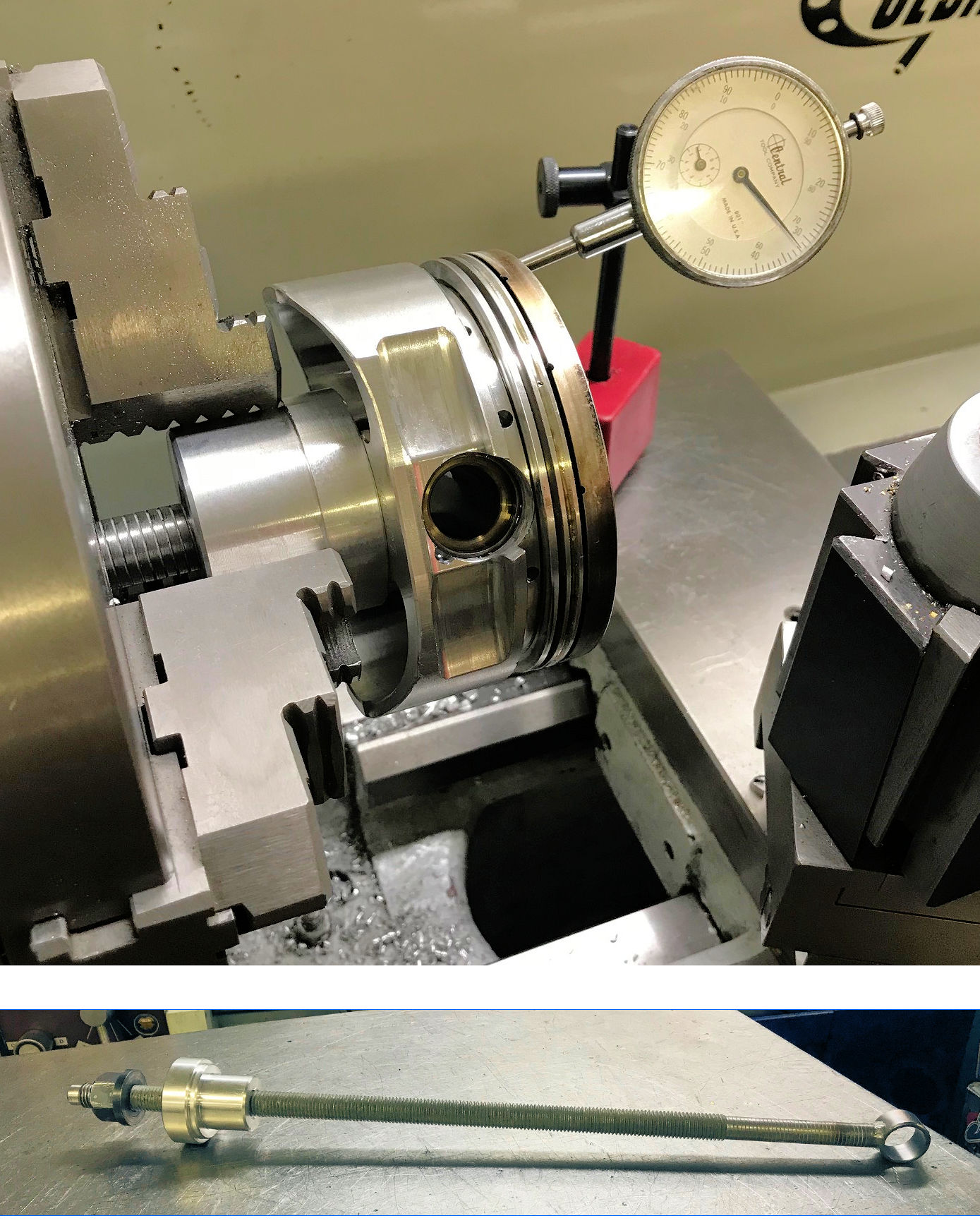

WHICH WAY IS UP When you are not sure which way the 2nd rings go in or cannot figure out the markings, remember, they are oil scrapers and have a tapered face. I hold one down to see which way it leans vs. a square. The side that leans towards the square is the top...