You can use a magnetic base from a dial indicator stand to hold your work while grinding parts like thin cover plates on a disc sander. It saves your fingertips. Tom Nichols Automotive Machine & Supply, Inc Cleburne, TX

You can use a magnetic base from a dial indicator stand to hold your work while grinding parts like thin cover plates on a disc sander. It saves your fingertips. Tom Nichols Automotive Machine & Supply, Inc Cleburne, TX

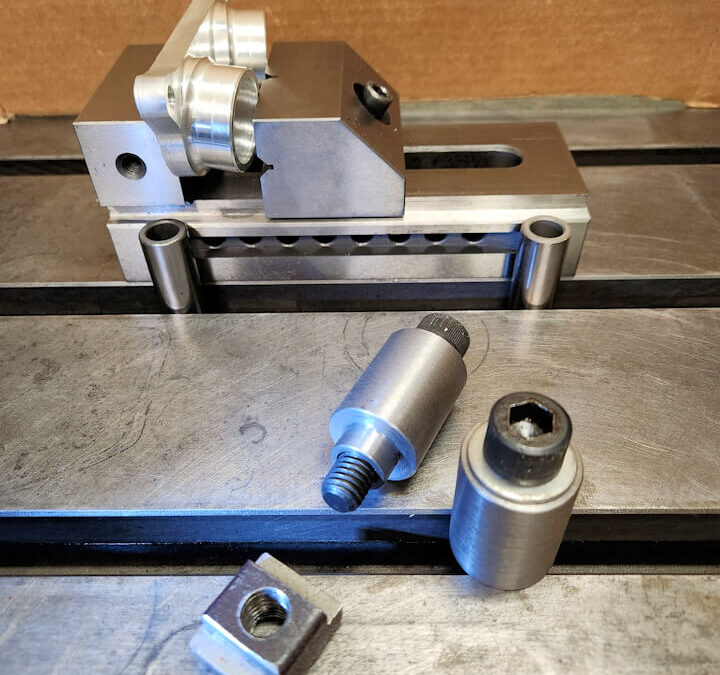

Use dowel pins or wrist pins that fit snug in your mill's T-slots to quickly tram or align a cylinder head, engine block, or vise. (shown using 18mm wrist pins). Also shown above is an alternative method. These simple to machine stepped pins, which fit snug in the...

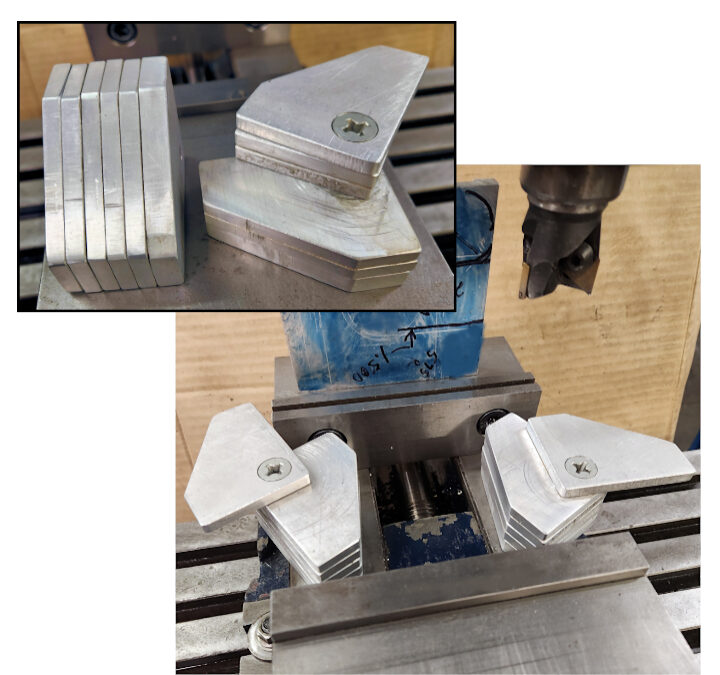

Often it is necessary to space the work piece up in the mill vise or off the machine’s table, when drilling or boring, etc. In addition to typical set of milling parallels, these shop-made variable height fixtures have proven to be very handy. Tom Nichols Automotive...

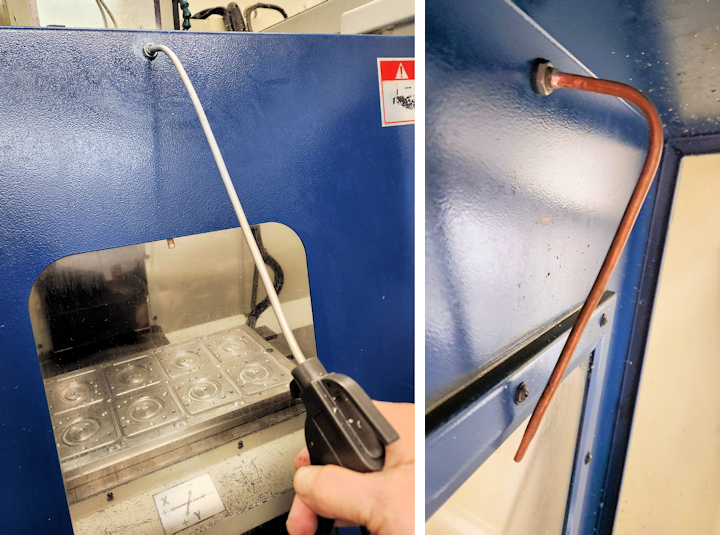

Often, you cannot see through your CNC mill's cabinet window because coolant is splashing on the inside of the window. Rather than create a mess by opening the door to take a peek, install this simple window air blast tube. Your parts list will include a 12" piece of...

Time is money and it helps to know where your tooling cuts, especially when it’s some that isn’t used every day. I use note cards, the back of my business cards, or tape to write myself notes for the next time I grab that tooling. Randy Torvinen Torvinen’s Machine...

Instead of using a file card/brush to clean pips & dirt from file teeth, flatten one end of a 6" to 8" length of 3/8" copper tubing. Use the copper tubing as a scraper to quickly remove debris from the file teeth. Rub chalk into the teeth after cleaning to help...