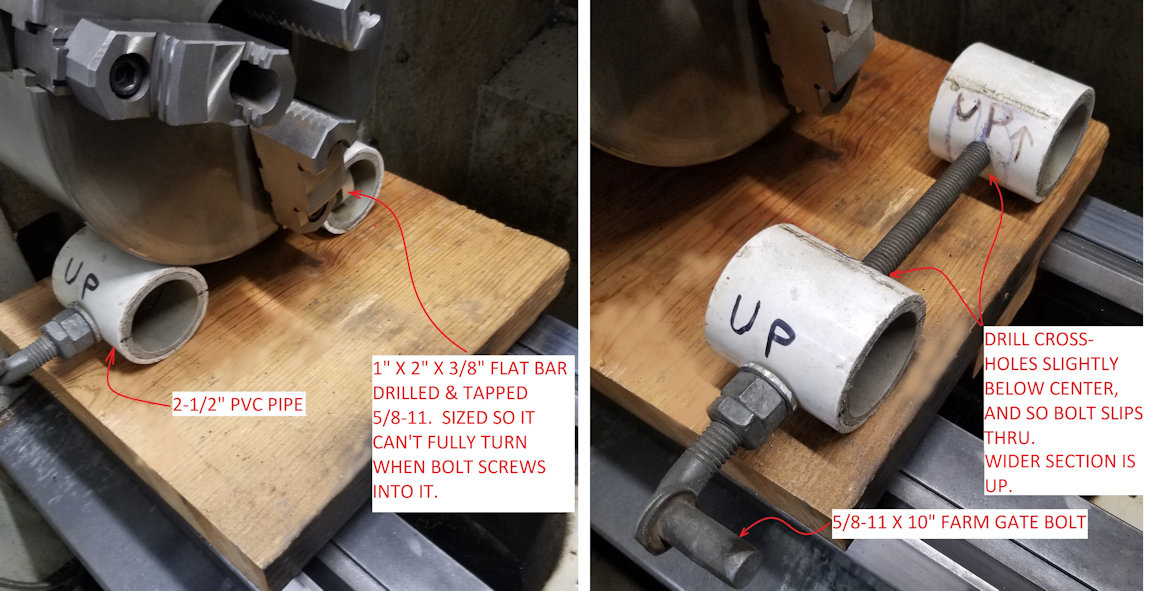

CHUCK SUPPORT I made this simple chuck support to help make changing chucks on my lathe & crank grinder much easier. Made from PVC pipe, a farm gate post bolt (or all-thread rod), and hardware, this adjustable chuck support lets the chuck slide off and on the spindle...