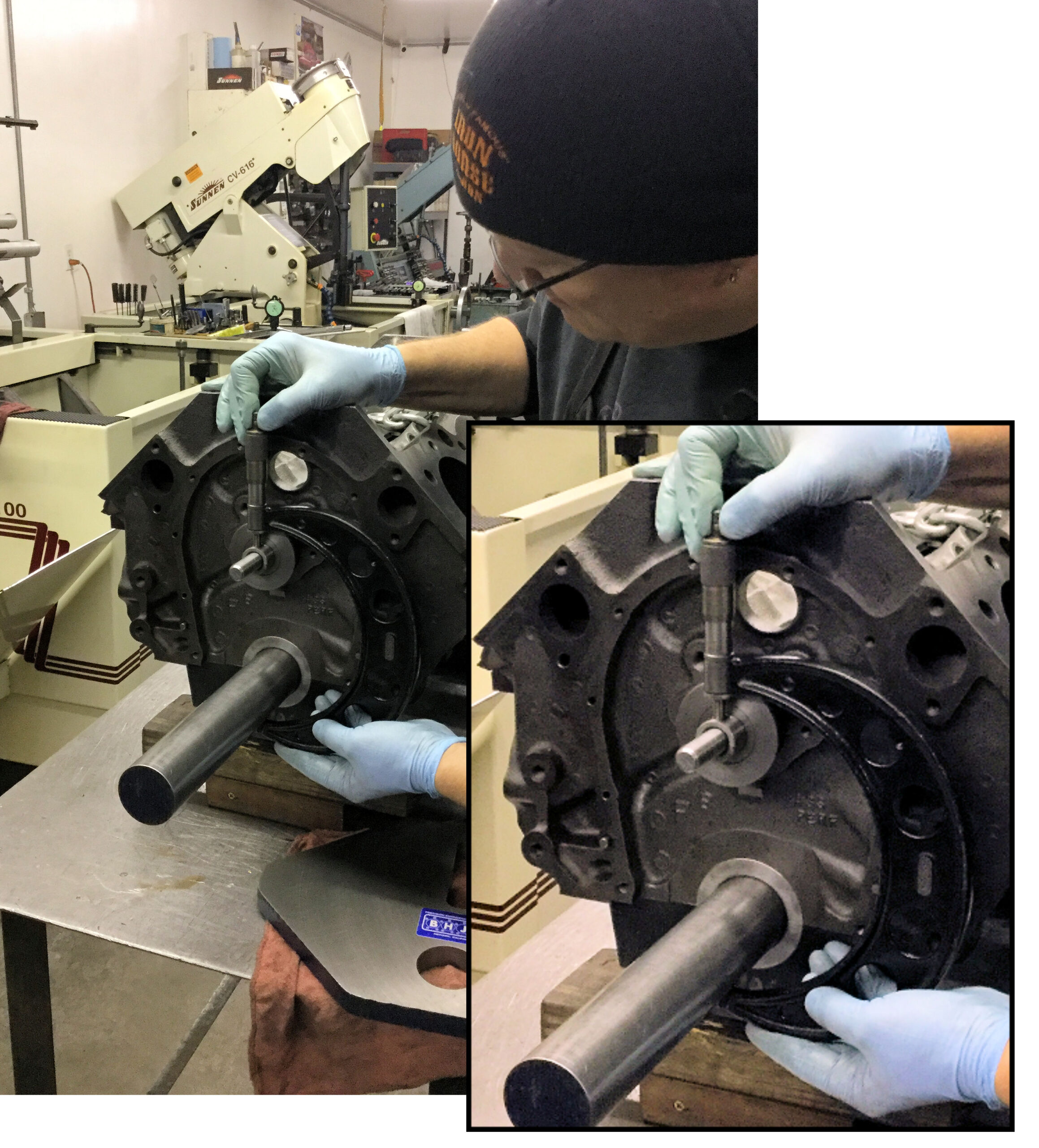

CAM TUNNEL CHECK

This is a quick and accurate way to check cam tunnel to crank centerline accuracy using the common Block Tru fixture. First, mount up the Block Tru fixture, be sure the front cone is flush with the plate and snug both front and rear. Next, remove the front plate and measure the outside dimension of the 1” cam tunnel spud to the 2” main bar, then deduct the radius for both (1-1/2”). That’s the C/C distance. Repeat for the opposite side. Installing a front and rear cam bearing is more accurate if the block has uneven chamfers. To check sway on the cam tunnel with the Block Tru, you have to square the block decks from one end. Next, remove the plate and cam tunnel cone mandrel, then install it on the opposite end of the block, facing the same way as on the previous side. (Note: It’s important that your index plate is very accurate. This can be checked by flipping it 180° after truing the decks and checking their alignment again.) Now sweep the deck to the index plate with the deck mic. If there is front to back sway in the cam tunnel, you’ll see that the decks are no longer parallel to the fixture as they were in the front. This will give you the direction you need to move the cam tunnel over. You can mock it up by shimming the cone to on side to find the exact amount you need to shift the cam tunnel. Ideally, you would correct the cam tunnel before indexing the decks and lifter bores, but if you don’t have the blueprint fixture, this will get you there. Deck the distributor gear end first and correct the cam position from there so you don’t affect gear mesh, unless you know you can or need to reduce some lash. I’ve done this on odd blocks that I don’t have the dedicated cam tunnel alignment tooling adapters for and it works great. You can make dedicated spuds for checking, but the cone allows you to mock up and shim for corrections.

Ron Flood

Cedar Machine

North Branch, MN

November, 2019