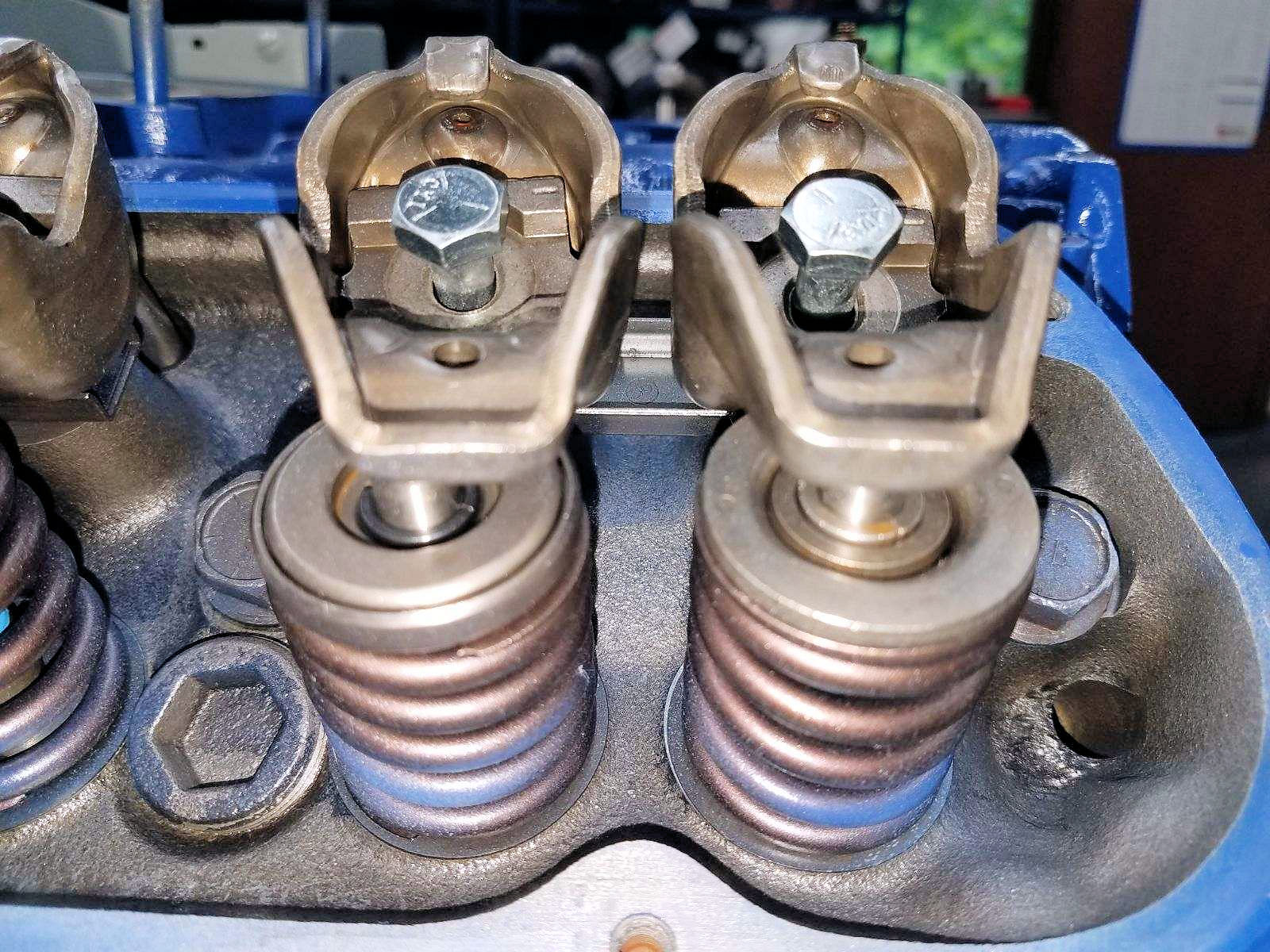

EASY CAM CHANGE I had need to change out the cam in a new build 351W. I used sixteen 1/2” longer 5/16” rocker arm bolts and left the lifters and pushrods in place. I rolled the engine upside down and turned the cam around once. I pulled the cam out with the engine...