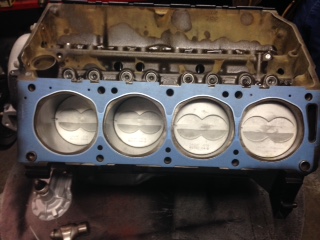

FE FORD I.D. They all say 352 on the side of the block, but this is how to identify which FE Ford block you have. A 352, 390 or 428 is cast in the bottom of the front right side water jacket hole. It’ll take a flash light, but you’ll see it if you look in the bottom...