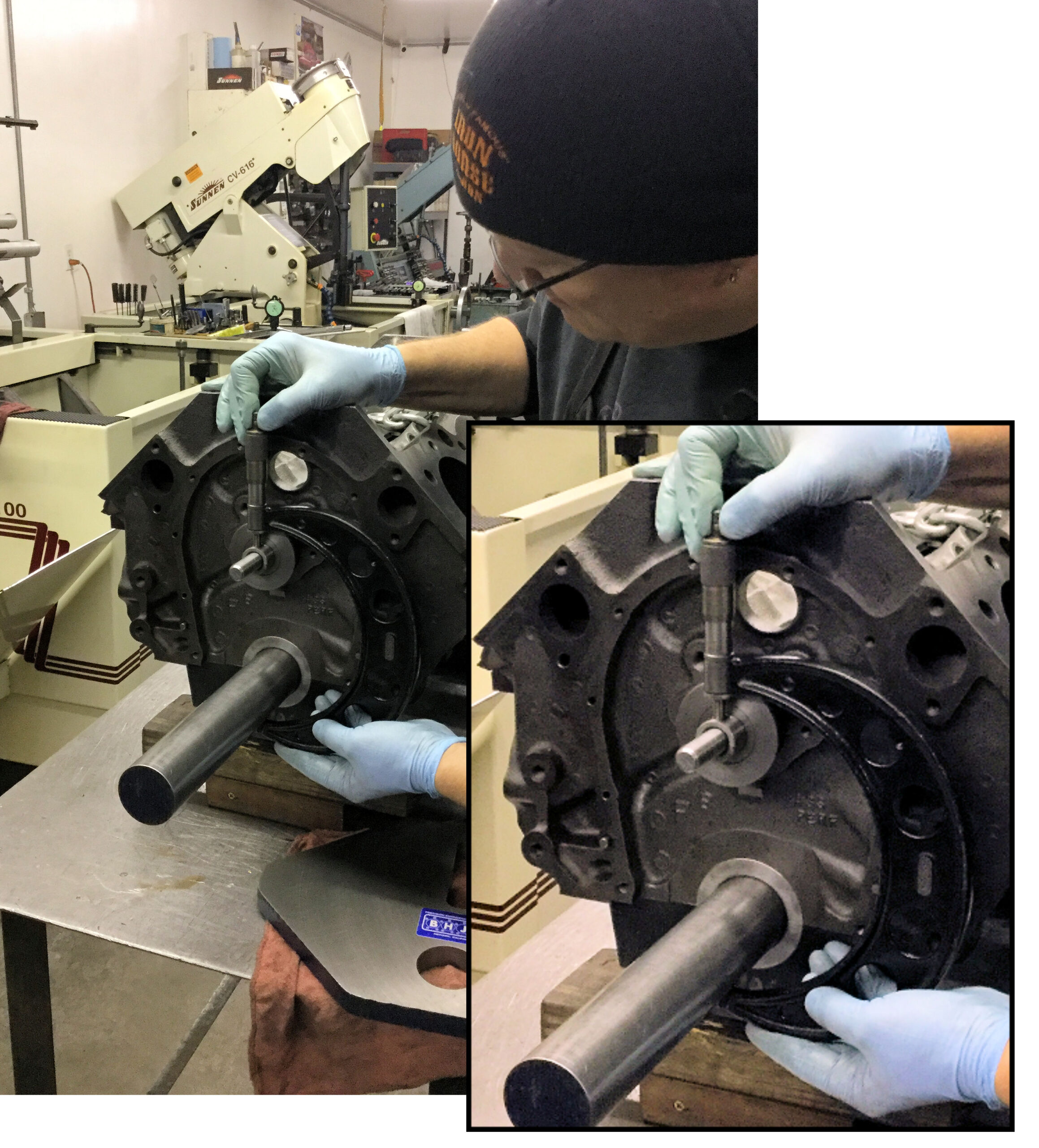

CENTER THE MANDREL This saves a lot of time when centering the mandrel on blocks with bed plates. Using an indicator on the mandrel with stone pressure against the mains, zero the indicator, release pressure with lever. Turn the mandrel 180 degrees, put pressure back...