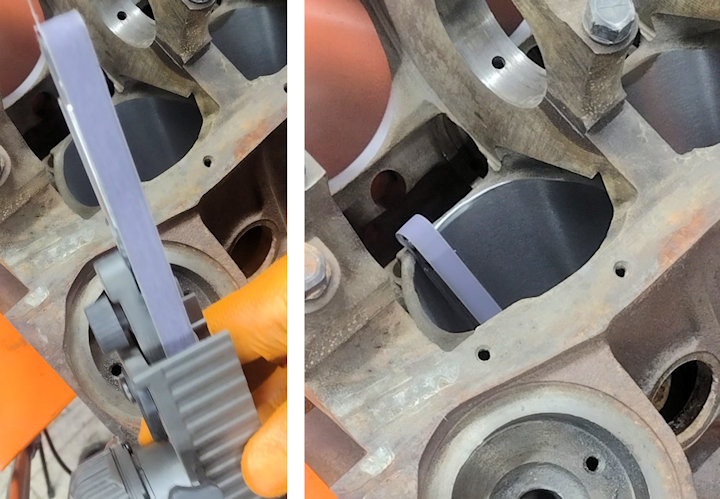

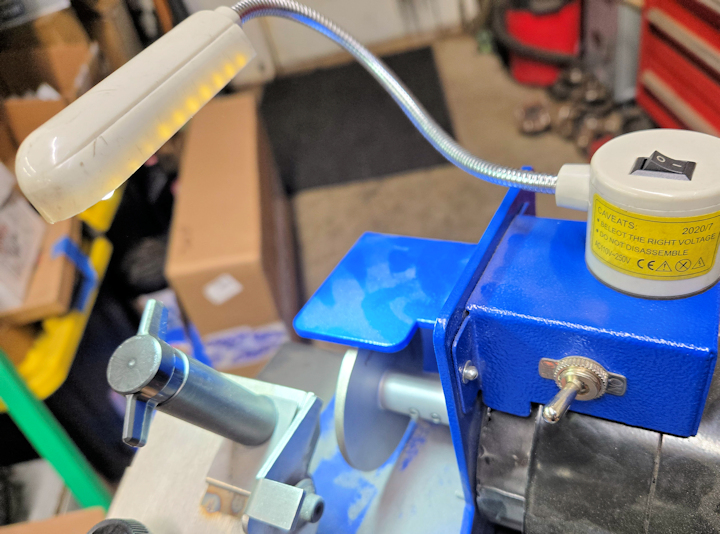

Freshly bored blocks leave a sharp edge on the bottom where the skirts protrude. I've found one of these little belt sanders are perfect to break that edge and add a chamfer. The outboard side I do from the crankcase and the Inboard side I put the sander through the...