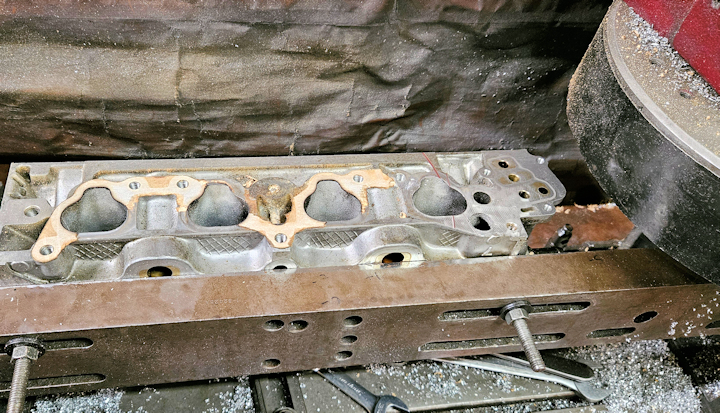

Sometimes assembling heads with beehive springs and retainers can be difficult because of their size. I find it easier to use a spring shim that fits the retainer and large enough to fit the spring compressor jaws. Randy Torvinen Torvinen's Machine Menahga, MN