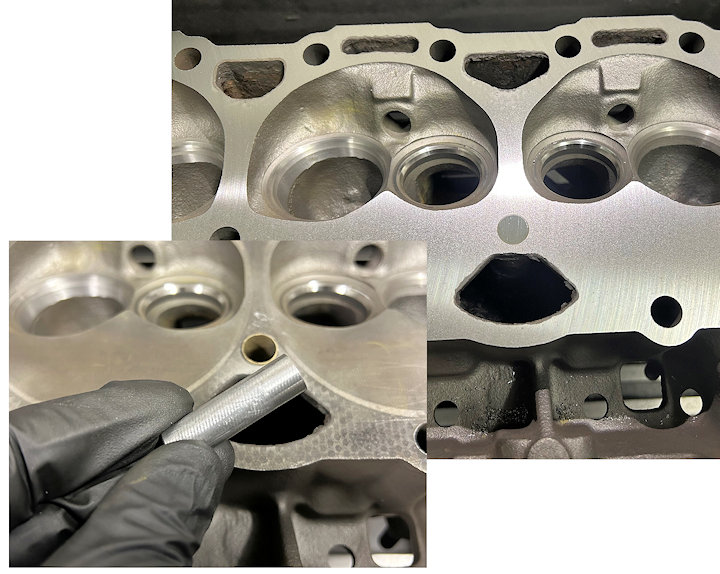

We all use different assembly lubricants for different areas of our projects. Just have many pill bottles with a smaller hole in the cap to prevent spilling if it gets tipped over. Just fill the bottle with a smaller level of lube so it won't pour out the top hole if...