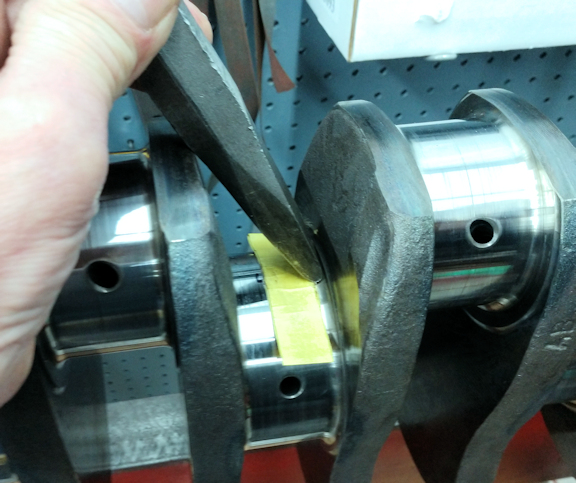

NO BOUNCE Most everyone straightens camshafts with a rounded chisel. Your efforts are more productive by supporting the cam. I lay it on a piece of carpet runner, and it makes it quicker and easier. I used to do it on the V -blocks, but this is much more effective....