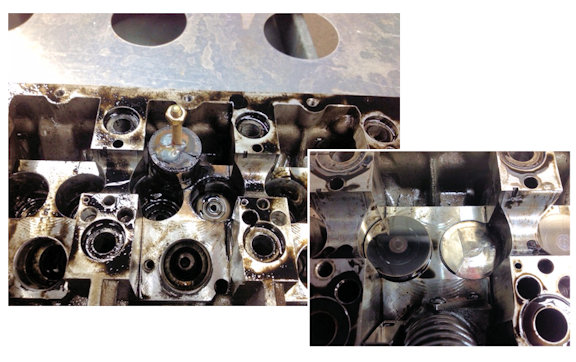

EXHAUST MANIFOLD SURFACING I grind exhaust manifolds on a dry belt surface grinder. Before I grind them, I bead blast the manifold surfaces to clean off the hard rust and carbon build up first. By doing this the manifolds grind easier and the belts last longer. Wes...