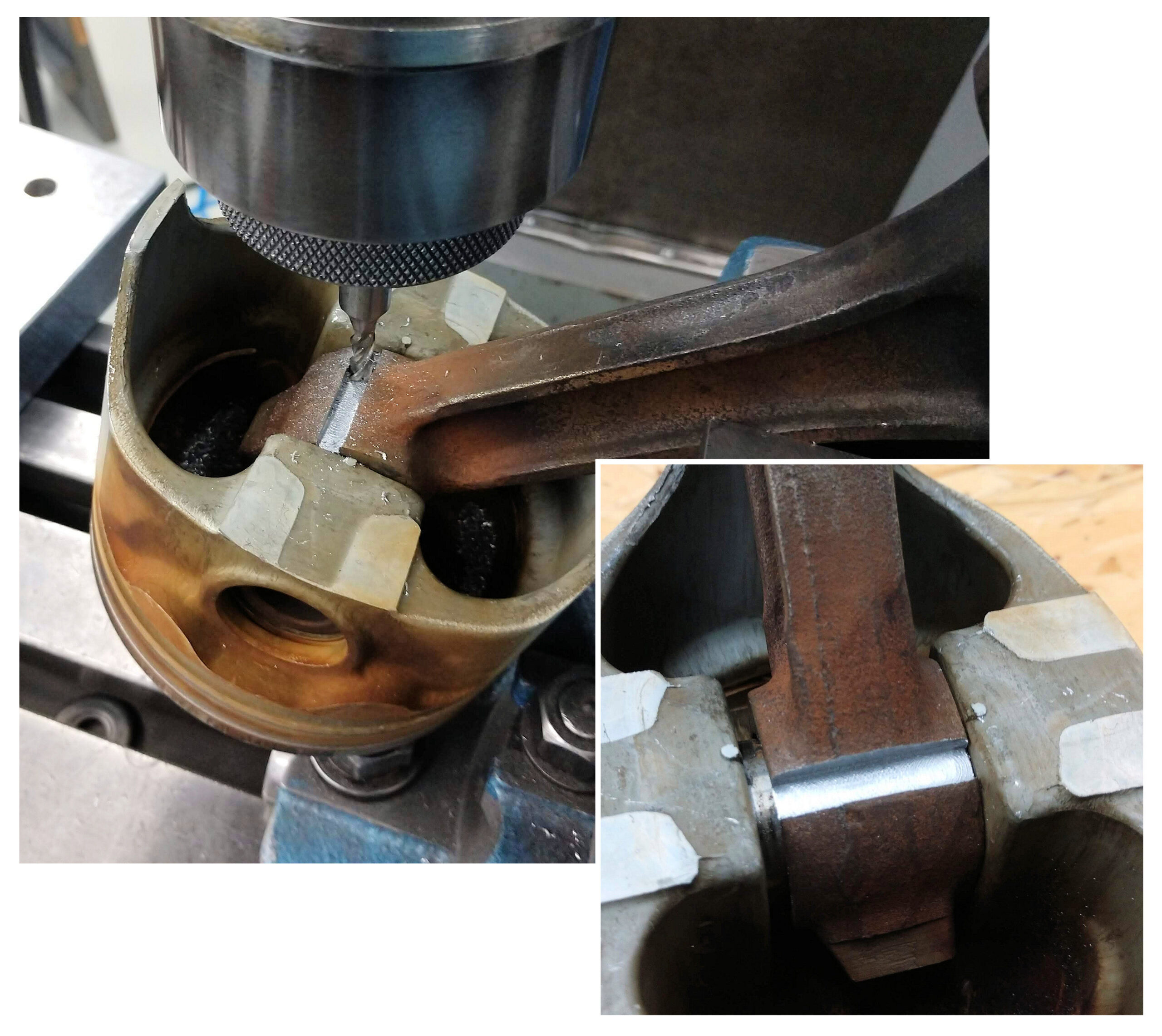

SAVE THAT SPECIAL PISTON When I really need to save a piston that does not have a good way to press it off without wrecking the sides, I mill a slot along the exposed lower side of the pin bore and it will release the pin fit. Then you can just tap the pin out. Randy...