NO MORE CAM BEARING ISSUES

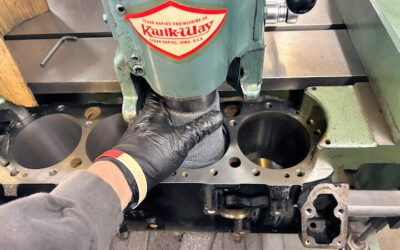

We’ve found that almost all issues related to camshafts being too tight in the bearings are caused by burrs in the cam tunnel which were caused by the original bearing installation at the factory. This is especially true with split cam bearings like an LS or late model Hemi. In our shop, before the block goes in the hot tank, we use a bore polishing flap wheel that’s smaller than the cam bore to very carefully just take the burrs off the big gouges. After that we use a dingle ball hone on a long extension and use honing oil to thoroughly deburr the cam tunnel bores. We started this process on LS Chevrolet’s, but have since been doing it on all blocks and haven’t had one go tight yet. This includes BB Chryslers! As a side note, LS Chevrolets usually have a giant burr at the opening of the cam bearing oil hole. This can be removed with a scrapper knife before running the dingle ball hone through. Now that everything is nicely deburred, those pieces of fractured metal from the burr won’t go through your fresh bearings.

Jake Sampson

Sampson Racing Engines

January, 2019

BORING TOOL ALIGNMENT

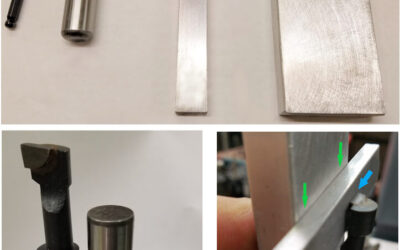

Here's an easy way to precisely align or clock a boring tool in a boring head. You'll need a dowel...