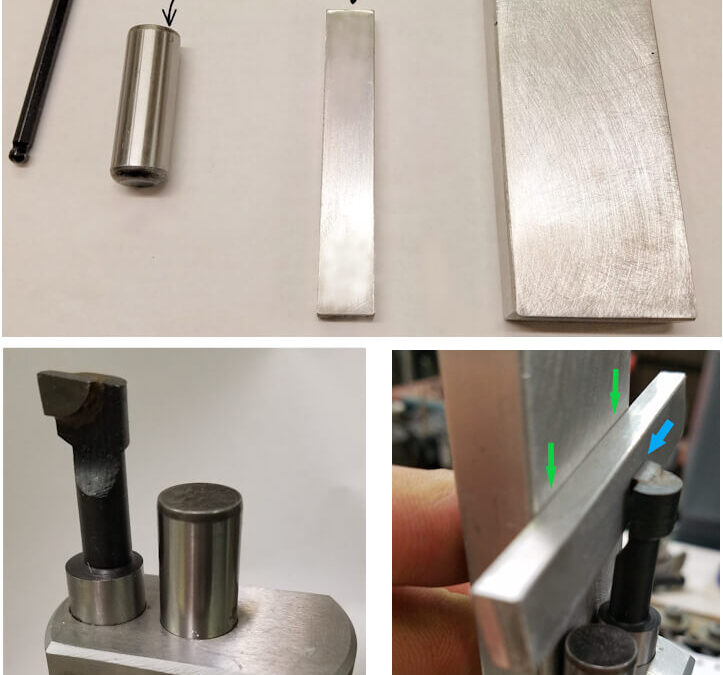

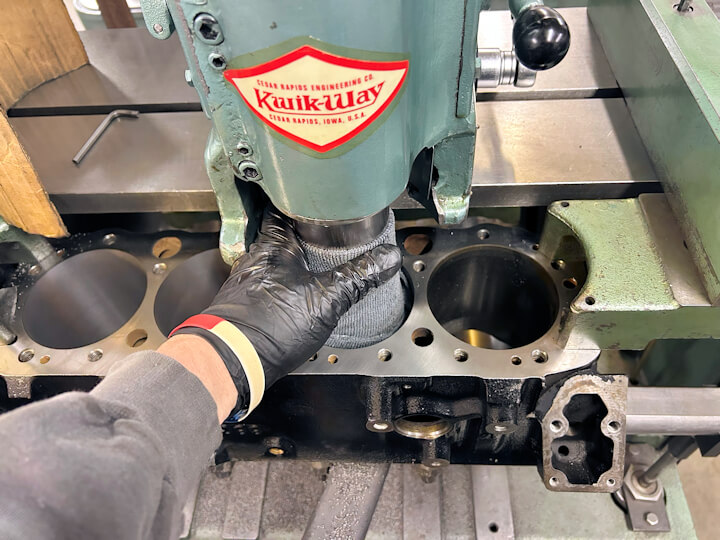

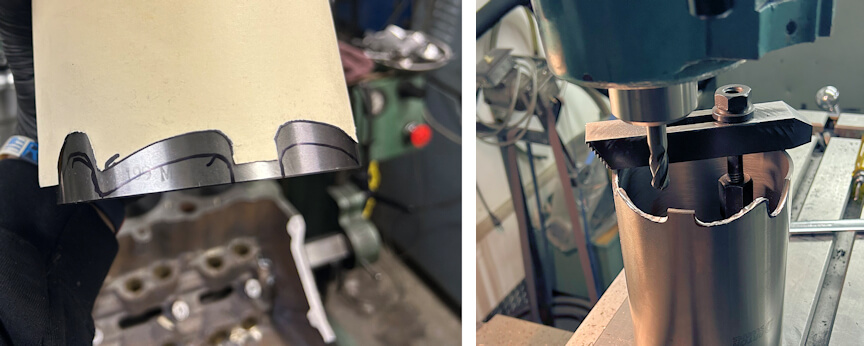

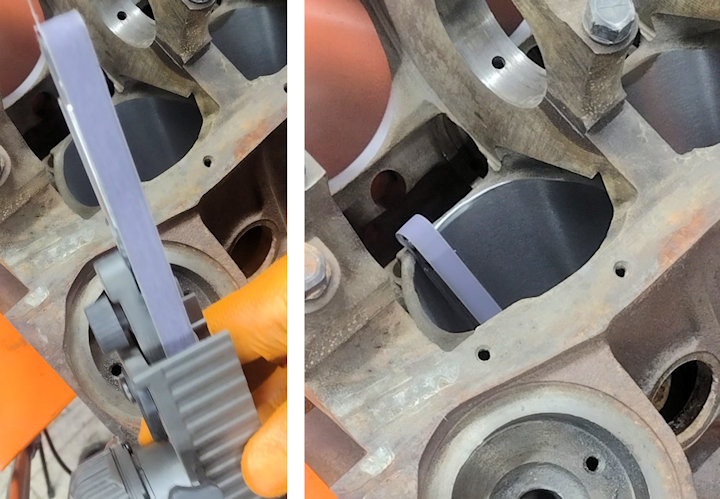

Here's an easy way to precisely align or clock a boring tool in a boring head. You'll need a dowel pin the same size as the tool shank to fit the boring head, a 1/4" thick x 1/2" aluminum flat bar, and a 1-1/2" x 1/2" aluminum flat bar, though the size is not...