by Donnie Hurt | Mar 2, 2026 | OPERATIONS

I often use one of my shop carts to lay out tooling for a machine job, like on the seat and guide machine, as shown. As you all know, it’s often a lot of pieces. To prevent anything from rolling off the table, I place a couple of shop towels down and use welding...

by Donnie Hurt | Feb 23, 2026 | CYLINDER HEADS

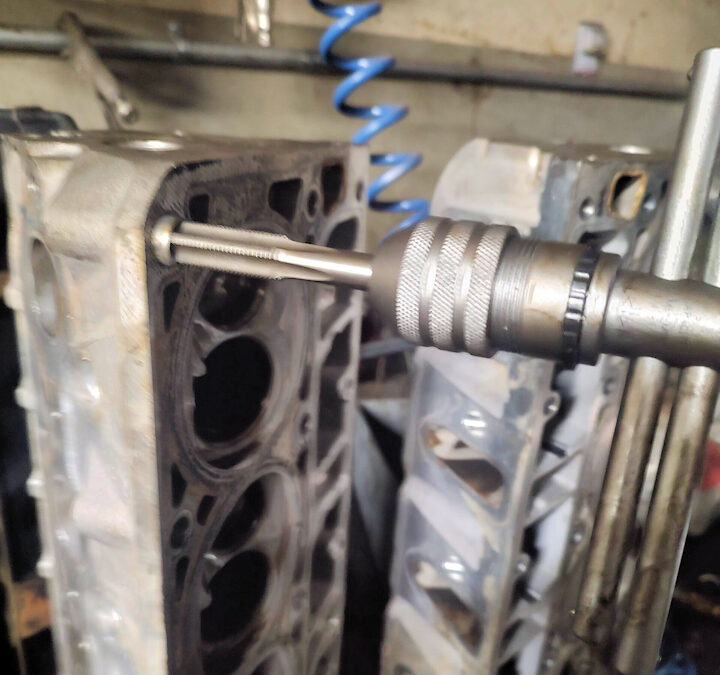

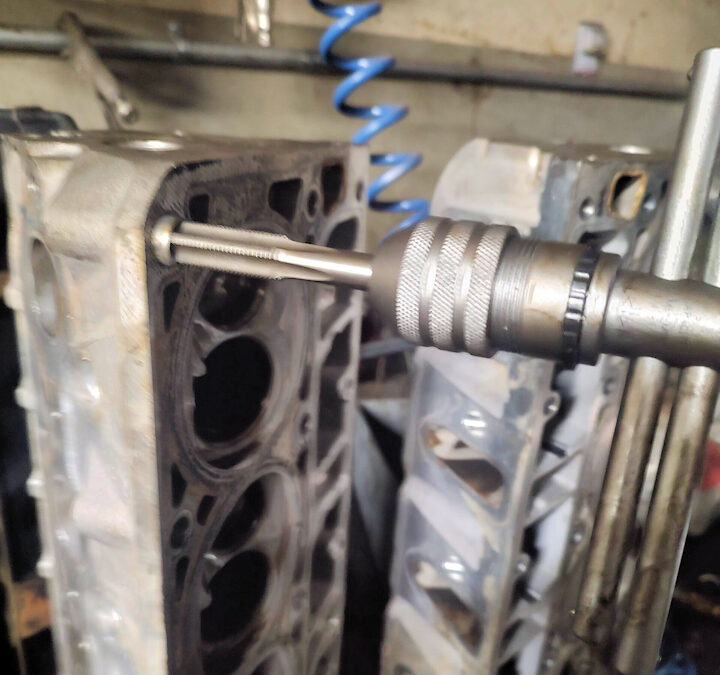

The hardest issue in dealing with LS heads is that most mechanics leave the head dowels inserted in position, and they’re extremely hard to remove. A simple solution is to insert a 14mm, tap in the dowels and twist as if you are going to tap. You can see that it...

by Donnie Hurt | Feb 10, 2026 | TOOLING

Up against a deadline to ship engines, we elected to machine the 20 chrome water necks to fit, rather than return them and order more. To securely hold the water necks in our lathe, we needed a custom-sized expanding arbor. I made the arbor from a 4″ length of...

by Donnie Hurt | Feb 10, 2026 | TOOLING

If you ever tried to get the locating dowels out of the Cummins main caps, you know that using a straight drift doesn’t work. The bolt holes are tighter on the opposite side of the dowel end. I made an expandable driver spud that allows the removal end to be...

by Donnie Hurt | Jan 26, 2026 | CRANKSHAFTS & CONNECTING RODS

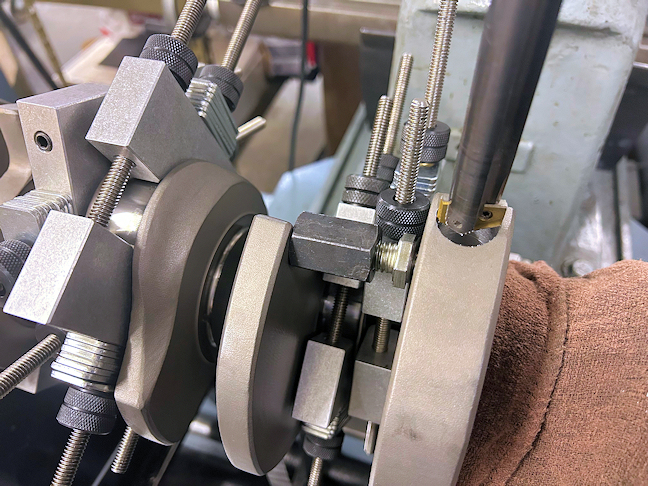

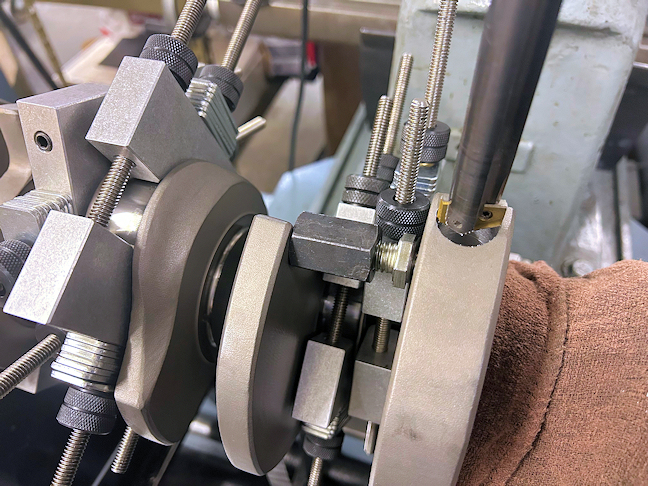

When drilling on cranks for balancing, install a simple jackscrew between the counterweights to eliminate flex at the rod journal. I use the same ones for drilling in line with the crank for heavy metal install, if the counterweight is unsupported on the drill...