by Donnie Hurt | Jul 5, 2018 | OPERATIONS

LUBRICATING WAYS When we use our resurfacing machines we usually let it travel just far enough to machine the length of the head or block that we are machining. This practice can cause a lack of lubrication to the Ways of one end of the machine. Once per day I let it...

by Donnie Hurt | Jul 5, 2018 | BLOCK WORK

FORD FE OIL TUBE REPAIR After reading the article on building Ford FE engines in the May issue of Engine Builder, I was reminded of a solution I came up with to repair cracked Ford FE blocks. It was not uncommon in their hay-day to see some oil in the cooling system...

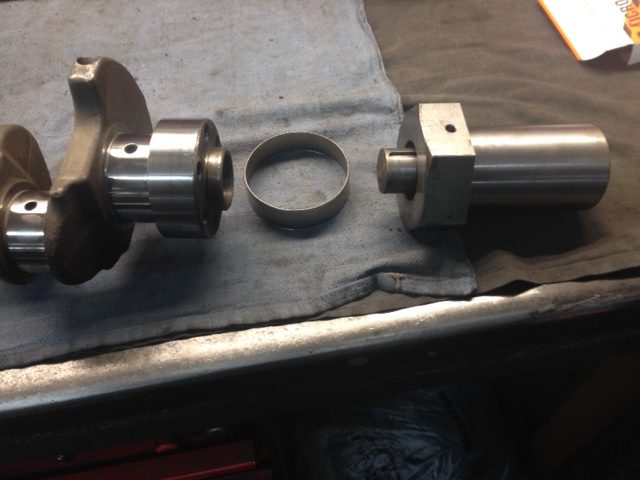

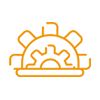

by Donnie Hurt | Jun 13, 2018 | CRANKSHAFTS & CONNECTING RODS

22R SPEEDY SLEEVE TOOL Installing a speedy sleeve on a 22R Toyota crank can be difficult because of the flywheel pilot flange sticking out of the back of the crank. I used a piece of tool steel, drilled a hole in it then installed a spring and a pin to hold it to the...

by Donnie Hurt | Jun 8, 2018 | OTHER SHOP WORK

REAR END SETUP MADE EASIER After I read the article about the 12-bolt rear end in the last issue, I wanter to share a solution to easily set pinion depth, without the hassle of pressing the bearings on and off. When rebuilding integral carrier type differential such...

by Donnie Hurt | Jun 7, 2018 | TOOLING

RECLAIMED TOOL Do you have a balancer puller with stripped out threads? Don’t throw it away! You can make a universal engine turning tool out of it. We turned a 1/2″ drive extension down in the lathe to fit the inside the bore of the tool, cut it to fit...