by Donnie Hurt | Apr 1, 2024 | DISASSEMBLY & CLEANING

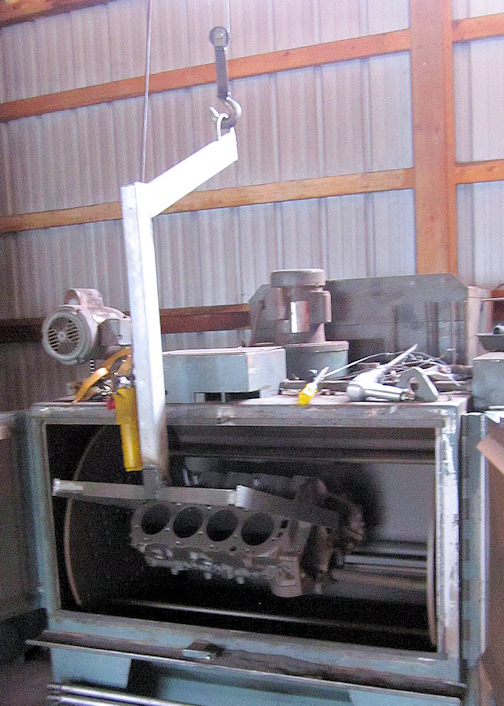

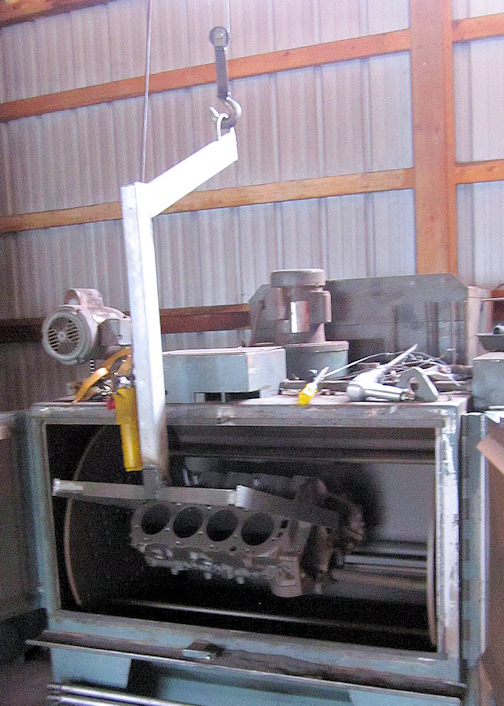

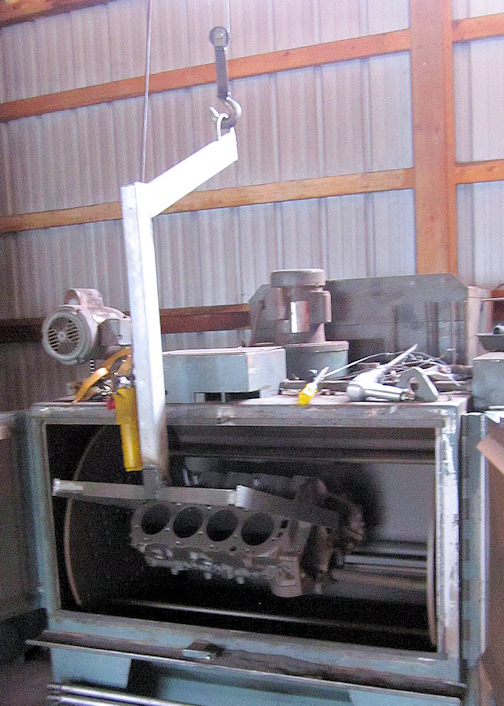

LOAD BLOCKS WITH EASE I have an older thermal cleaning system by Peterson. The shot blaster is designed more for cylinder heads than blocks as it is a side loading machine. To wrestle blocks into the machine was not reasonable so I came up with this simple solution to...

by Donnie Hurt | Apr 1, 2024 | PISTONS & RINGS

LS PISTON PIN SIZE Stock GM LS full floating connecting rods use a .943″ pin and stock LS press rods use a .945″ pin. Some aftermarket forged pistons designed to use a stock LS 6.098″ length rods come with the .945″ pin type. Pistons can be...

by Donnie Hurt | Apr 1, 2024 | TOOLING

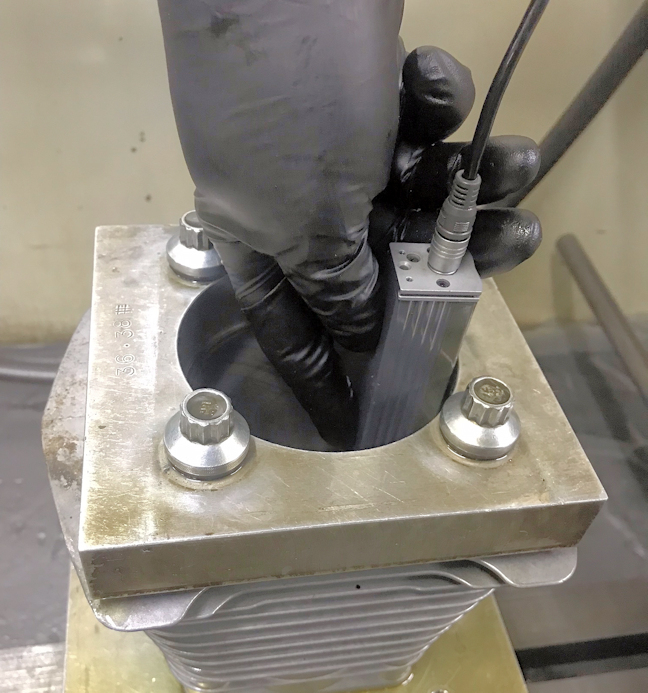

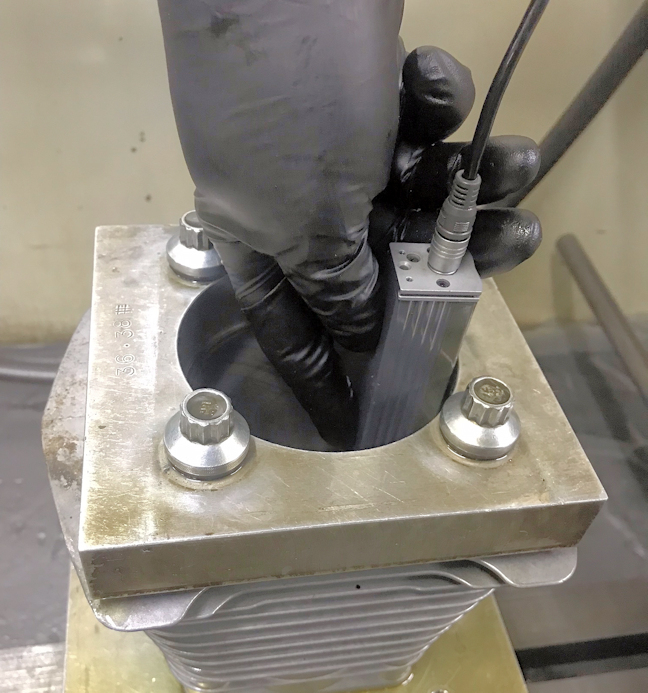

DIAMONDS AREN’T ALWAYS FOREVER When using my profilometer for bore and surface readings, I hold the drive on the workpiece until the stylus has retracted and recorded it’s reading. Then, I lift it off and let it retract without touching the workpiece. This...

by Donnie Hurt | Apr 1, 2024 | TOOLING

A SIMPLE REMINDER Even well-regarded brand name dial indicators typically have a +/- accuracy equal to 1X to 2X their resolution and can read +/- 0.0005″ after 2 to 3+ revolutions. For example, a Mitutoyo 0.5″ range, 0.0001″ resolution indicator has...

by Donnie Hurt | Mar 1, 2024 | CYLINDER HEADS

ASSEMBLY LUBE I keep a container of engine assembly lube at my cylinder head work bench. A good dab of assembly lube holds spring cups and or shims in place during cylinder head assembly. Too many times the shims came off and got mixed up, so I started doing this and...