by Donnie Hurt | Feb 1, 2024 | DISASSEMBLY & CLEANING

MAKE IT TALLER Frustrated with my dowel pin puller not always working to remove the stubborn deck pins, I will put a few tack welds on an old rocker stud placed on top of the dowel pin. Anything would work, though a length of all thread might be best. Then I take a...

by Donnie Hurt | Jan 1, 2024 | BLOCK WORK

KNOCKING OFF THE EDGES Before installing cam bearings, make sure to chamfer any oil holes and clean up back grooves of any sharp edges. This is especially critical with aluminum blocks. I like to give these areas a little buff on the mounted wheel to finish. This will...

by Donnie Hurt | Jan 1, 2024 | TOOLING

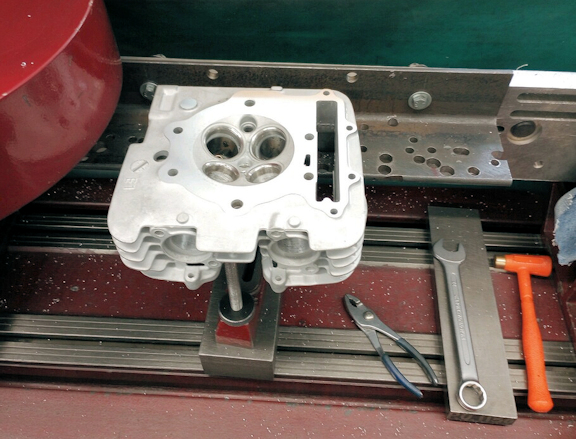

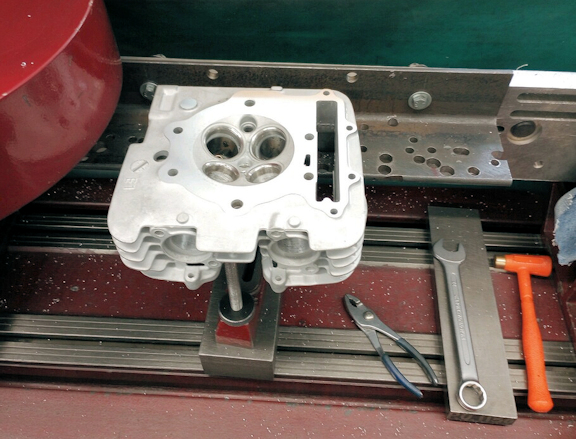

EASY MOUNTING When I need to mill something that’s hard to set-up and hold, I use this 19″ 3″x4″ 3/8″ thick angle iron. I just bolt on the head, ex manifold or whatever won’t work out on the machine’s mounting plate....

by Donnie Hurt | Jan 1, 2024 | TOOLING

LUG STUD DRILL GUIDE I made this drill guide to quickly center existing lug stud holes when upgrading to larger lug studs in axles. To begin, the round bar needs to be approximately 2″ long, and approximately 1/4″ larger in diameter than the drill...

by Donnie Hurt | Jan 1, 2024 | CRANKSHAFTS & CONNECTING RODS

RELUCTOR WHEEL INSTALLATION TOOL We made our own reluctor wheel installation tool for LS engines, and it works like a charm. We used junk materials from around the shop, including an old valve stem, and have about 2 hours of labor into making it. A chunk of 1/2″...