by Donnie Hurt | Apr 1, 2023 | CYLINDER HEADS

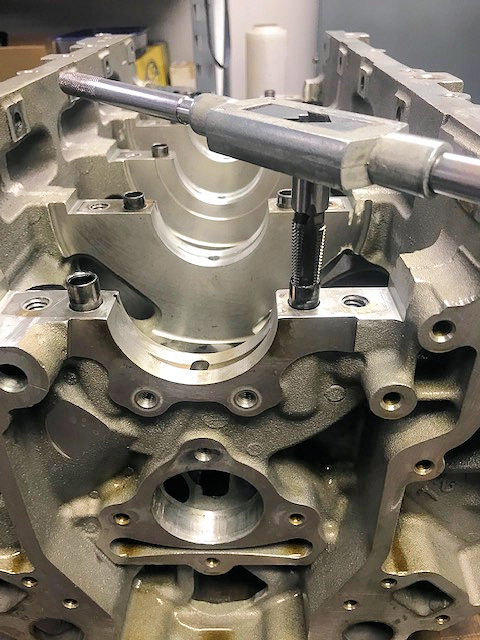

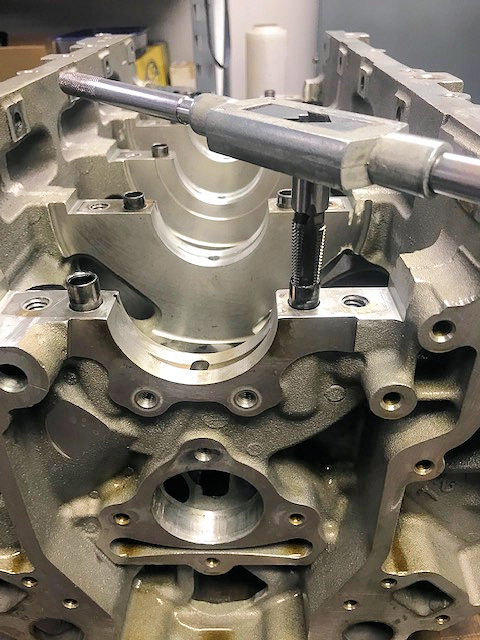

DAMPER/VALVE GUIDE INSTALL TOOL We are a two-man shop, so sometimes wrestling a head this size in the shop press is a bit sketchy. To reduce risk of injury or damage, we installed the guides using our harmonic damper installation tool. It may not be the quickest...

by Donnie Hurt | Apr 1, 2023 | TOOLING

ADD A MAGNETIC TOOL HOLDER I’ve had this inexpensive magnetic welder’s square for years and have never found a good use for it, until now. This red magnetic square save time spent bending over to retrieve the tools off the floor after blowing off chips...

by Donnie Hurt | Apr 1, 2023 | DISASSEMBLY & CLEANING

FLASH IN THE DRAIN PAN I see a lot of people struggle with iron parts flash rusting after spray washing and rinsing with hot water. If you finish rinse with cold water, and blow it off, it pretty much stops the flash rust before it can start. You can then spray some...

by Donnie Hurt | Apr 1, 2023 | BLOCK WORK

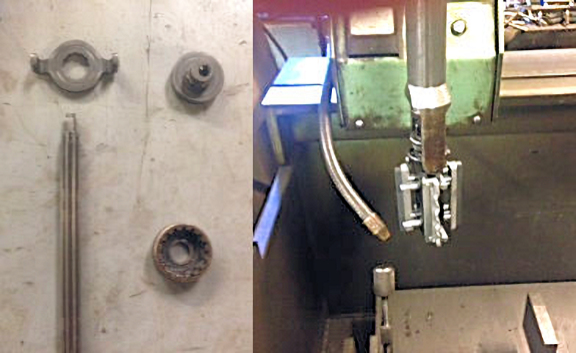

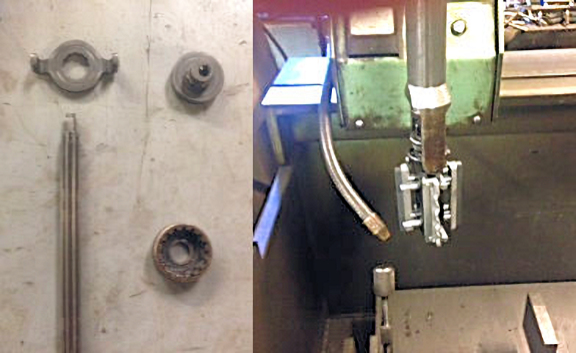

ROTTLER HM3 HONE REPAIR Here is how you can repair your Rottler hone head since Rottler does not service this any longer. Use a Regis part number RSI218. You will need to drill out the top of pinion to remove the expander nut. Then cut the top of the shaft and drill...

by Donnie Hurt | Feb 1, 2023 | DISASSEMBLY & CLEANING

DOWEL REMOVAL This is an easy and clean way to remove hollow dowel pins found in connecting rods or mains. Start tapping the I.D of the dowel with an NPT tap. Once it starts to cut it will spin the dowel and with upward pressure the dowel can be removed and reused....