by Donnie Hurt | Dec 1, 2022 | CRANKSHAFTS & CONNECTING RODS

RECONDITIONING DIESEL CONNECTING RODS The goal when servicing diesel connecting rods is to ensure the full set of rods are straight, on size and of the correct length. They should be machined back to the original OEM specification. Honeable bushings are acceptable if...

by Donnie Hurt | Dec 1, 2022 | CYLINDER HEADS

DRAG MARKS When resurfacing aluminum heads where the seat insert is contacted, sometimes the tool bit can leave tracking or drag marks across the deck surface in that area. To avoid this, you may be able to simply chamfer the seat slightly before the finish cut, so...

by Donnie Hurt | Nov 1, 2022 | TOOLING

LONG TAP EXTENTION Chasing threads at the bottom of deep holes in engine blocks can be done with a pulley tap. Pulley taps are made with an extra-long shank. However, if you do not have a pulley tap, you can make a tap extension. Here’s how: Cut off the threaded...

by Donnie Hurt | Nov 1, 2022 | BLOCK WORK

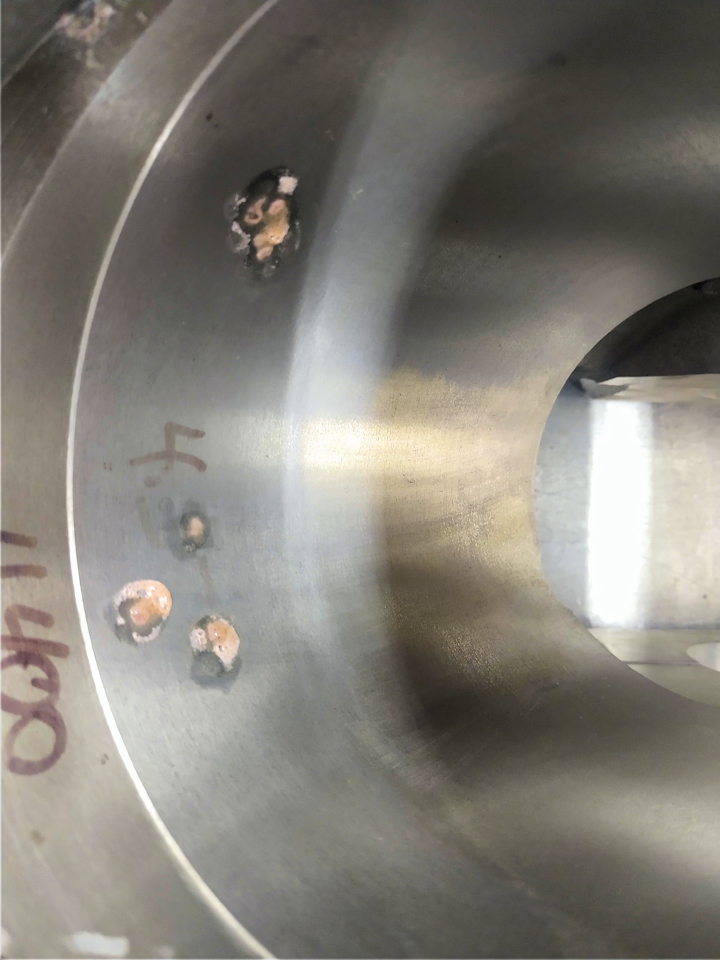

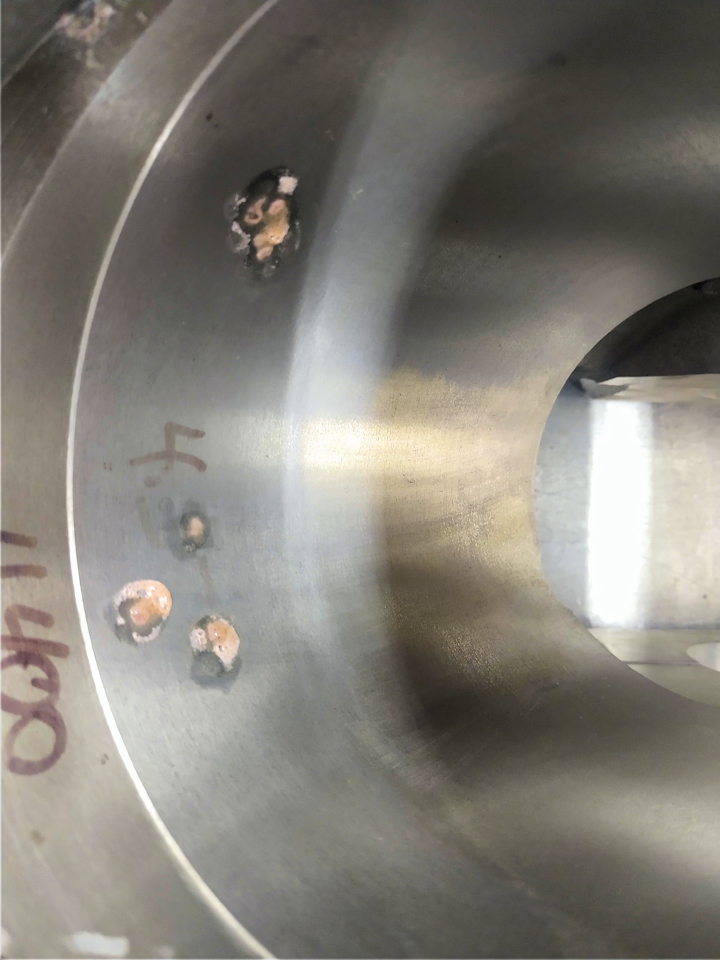

RUST PITS When rebuilding vintage engines, a person must deal with rusty components. When I have rust pits in the cylinders that do not require sleeving, I treat them with rust dissolver jelly right before honing. It may take a few times to get it and a small...

by Donnie Hurt | Nov 1, 2022 | OTHER SHOP WORK

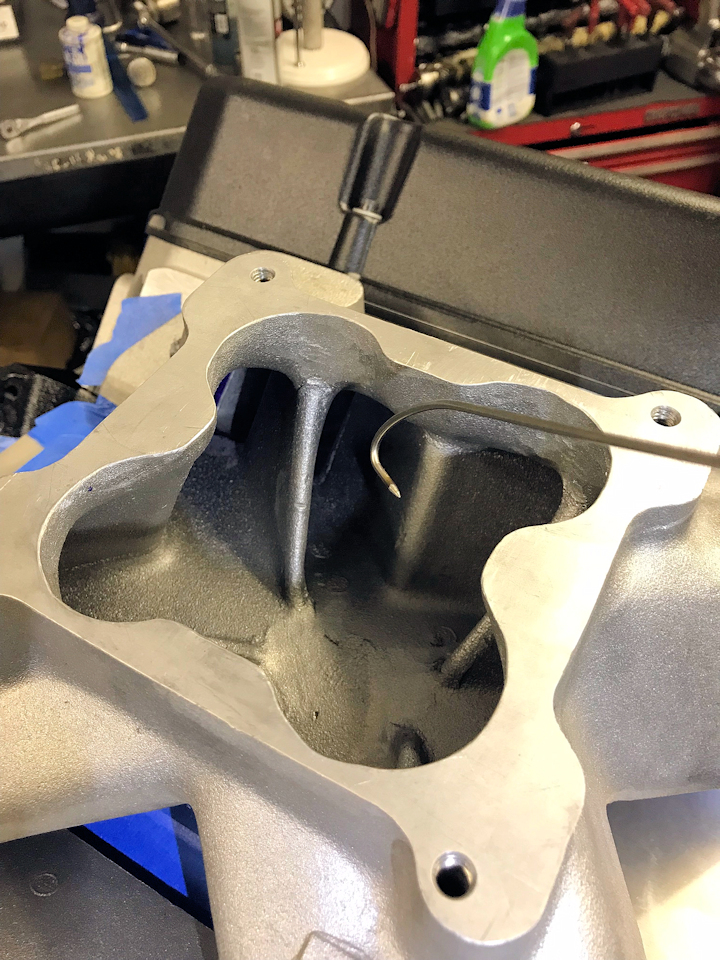

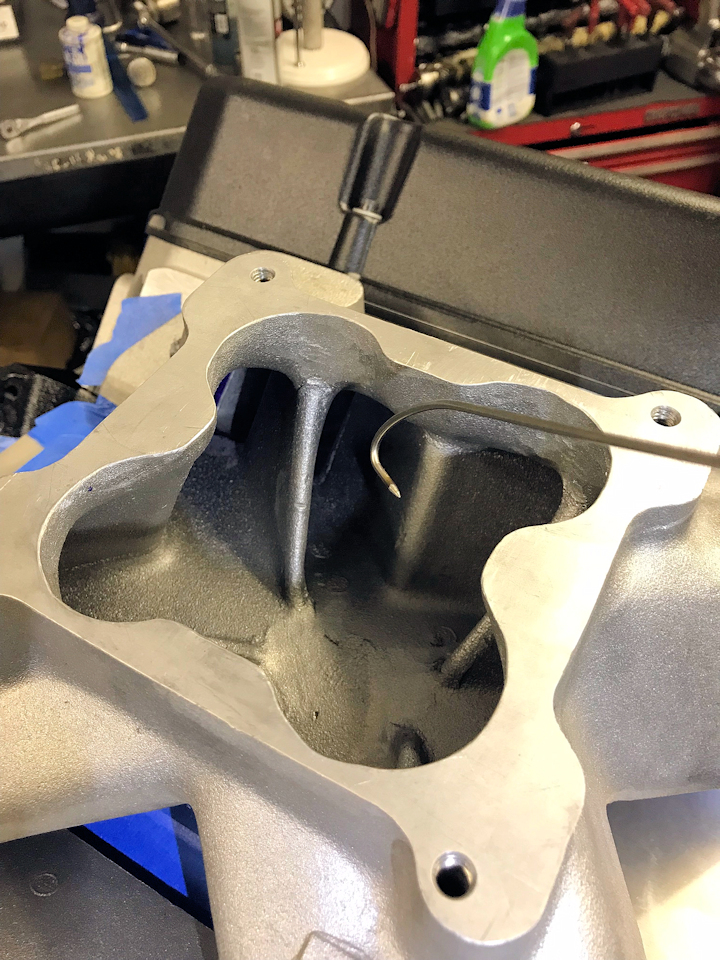

REVERSE SCRIBE TOOL When port matching intake manifolds, I make some different shaped “Reverse Scribes” to get in and scribe mark the dye on the intake manifold flange side. It works great, is often easier than marking and transferring an intake gasket...