by Donnie Hurt | Jul 1, 2022 | ASSEMBLY

MORE ON BALANCER HUBS I have several balancer hubs that I’ve honed for slip fit tools. If you have an engine where there is a timing cover index issue from either poor dowel pin alignment or a crank centerline issue, you can still locate it properly. Remove the dowel...

by Donnie Hurt | Jun 1, 2022 | TOOLING

DON’T FAKE IT, MAKE IT The only way to make money in your shop is to be able to do the job quickly and efficiently. This means having the right good equipment and tooling. But when you get caught needing a special tool and there’s no time to wait, just...

by Donnie Hurt | Jun 1, 2022 | CYLINDER HEADS

RECYCLED MEASURING TOOL To install valve guides on my heads, I just make custom fit measuring tools out of the 6″ steel rules I get at the trade shows. I cut them to fit in the lifter bores of the overhead cam engines. It’s quick and simple. Matt Peebles...

by Donnie Hurt | Jun 1, 2022 | PISTONS & RINGS

FILL IT TO THE TOP If you have a piston with a dome volume, you’re unsure of, here’s an easy way to check. Wrap a single layer of thick packing tape around the head land, taller than the dome. It will maintain the full round shape if you’re careful....

by Donnie Hurt | Jun 1, 2022 | CRANKSHAFTS & CONNECTING RODS

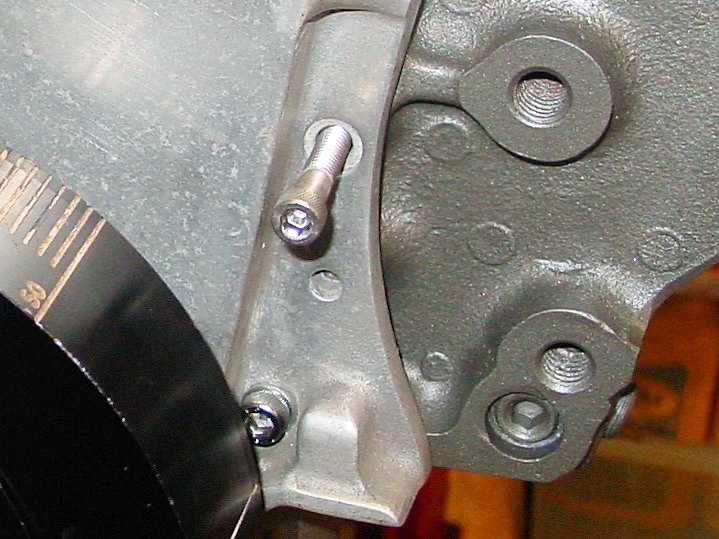

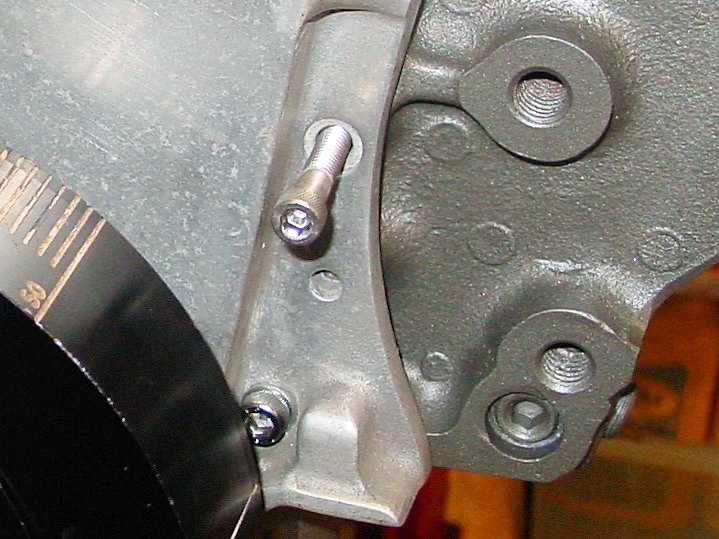

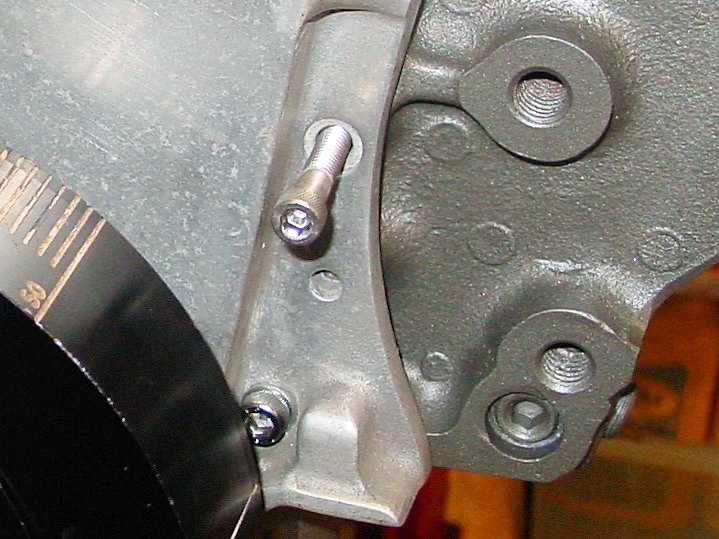

INSTALLATION TOOL TOOL When installing a reluctor wheel on an LS crankshaft, using the brand name alignment tool, use a piece of 4.5″ pipe, notched and with a bar welded on the back to take the hammer blows. I can avoid banging on the tool and this provides a...