by Donnie Hurt | Oct 6, 2025 | OTHER SHOP WORK

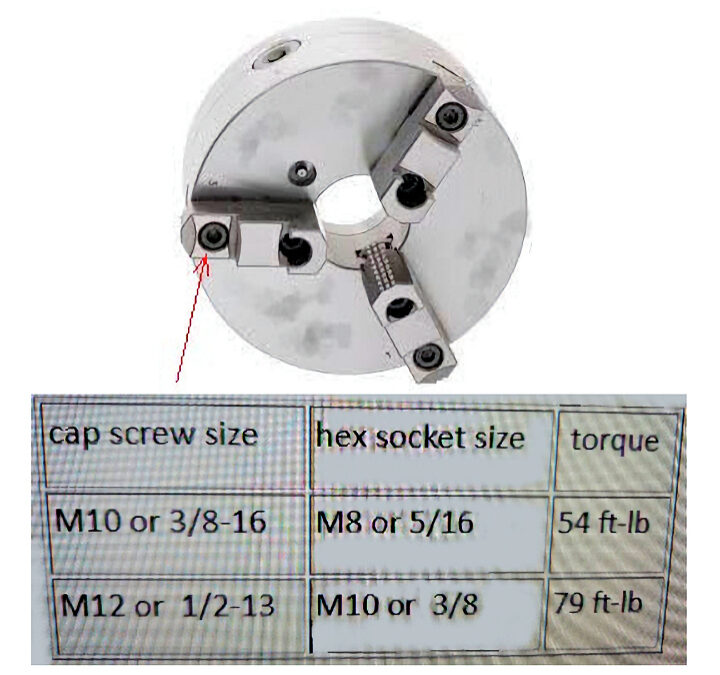

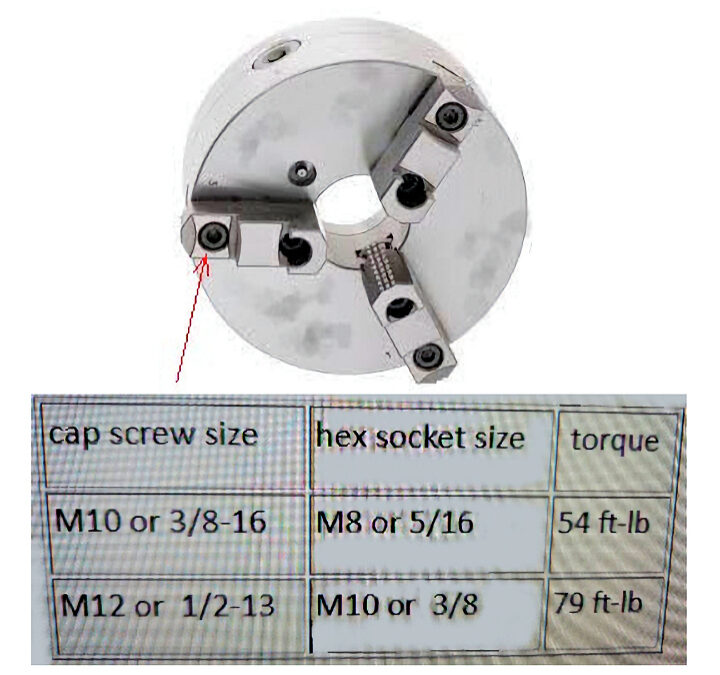

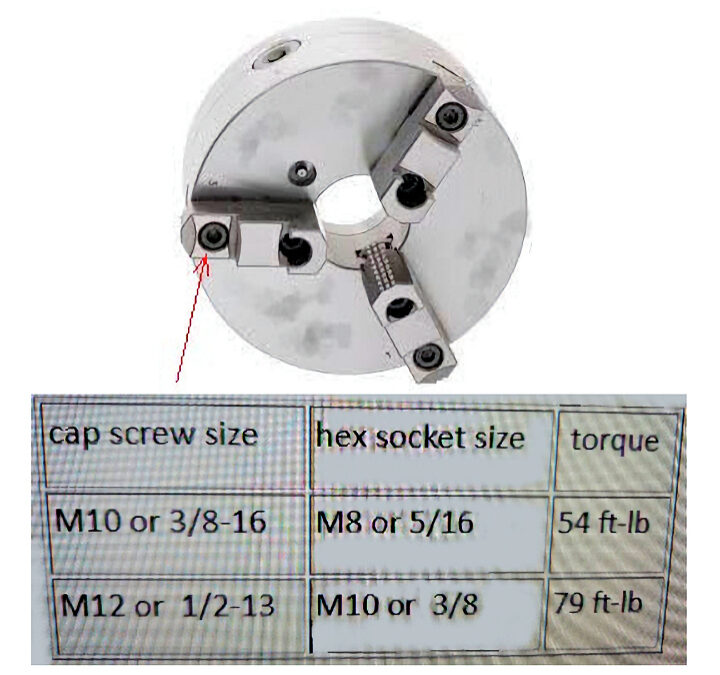

A small reduction of run-out on lathe or crankshaft grinder chucks, with bolt on top jaws, can often be achieved by an even torque of the socket head cap screws that attach the top jaws. I’ve included the proper torque, by cap screw size, for the more common American...

by Donnie Hurt | Oct 6, 2025 | CAMSHAFTS & VALVE TRAIN

When breaking in flat tappet cams, I place these Rare Earth Magnets on the top of the outer head bolts, and I’ll use break-in rocker arms when the open pressure is high. These and a magnet on the drain plug let me keep an immediate eye on ferrous metal, and I...

by Donnie Hurt | Oct 1, 2025 | LUBRICATION & COOLING, TOOLING

It’s hard to trust many parts today. We’ve seen new oil pumps with issues right out of the box. We always take them apart to clean and inspect, lube up the pressure relief valve, and put them back together. Old style shaft driven pumps are pretty easy to...

by Donnie Hurt | Oct 1, 2025 | TOOLING

To turn a small block Chevy crank with the damper on, I cut off an old crank snout and remove a few thousandths from the diameter so it would slide inside the damper. Than I can use it along with my crank-turning socket. Sylvain Tremblay Les Ateliers de Moteur...

by Donnie Hurt | Sep 22, 2025 | CRANKSHAFTS & CONNECTING RODS

If you find yourself having to fill a counterweight hole when balancing, here’s a tip. Once your piece of metal is installed, drill and tap for a tapered crack repair plug, as a secondary retention procedure. This, along with the press fit, gives you absolute...