by Donnie Hurt | Mar 1, 2022 | DISASSEMBLY & CLEANING

BACK TRACKING To save my old shoulders and back I had to come up with a way to get the big diesel blocks in and out of the spray washer. This track, with short pieces of angle iron welded on, catches on a brace. It lets me pry them in and out until the chain hoist can...

by Donnie Hurt | Mar 1, 2022 | TOOLING

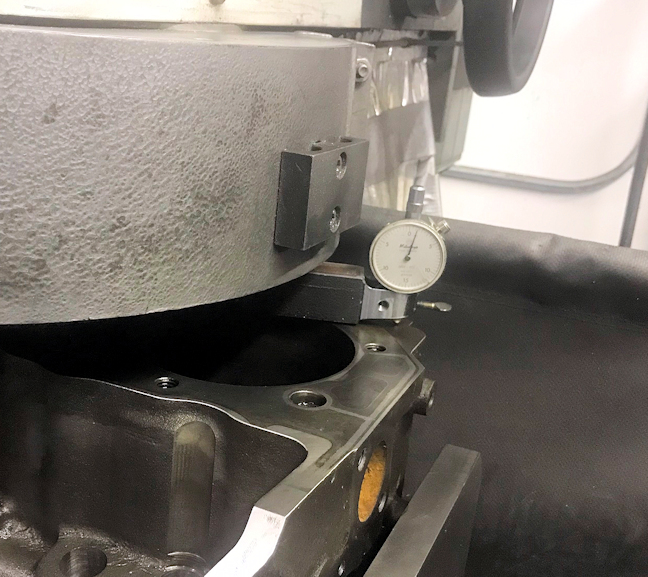

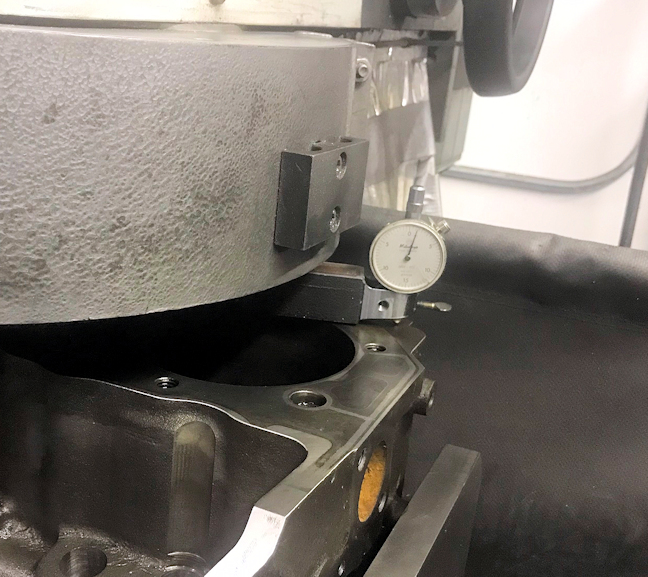

MAGNETIC INDICATOR On my surfacer, I use a simple popular universal magnetic base with a dial indicator to tram my work piece or index fixture. This dials the actual head in dead-on and works great for machines without an indicator rail. It also allows you to tram...

by Donnie Hurt | Mar 1, 2022 | CRANKSHAFTS & CONNECTING RODS

PRIMING PUMP You can make a GM-LS engine priming tool using just about any oil pump. I used a new big block Chevy M77 pump that I already had. I tapped the inlet and outlet to NPT threads and installed fittings to adapt to rubber hoses. The pressure side needs to...

by Donnie Hurt | Mar 1, 2022 | CYLINDER HEADS

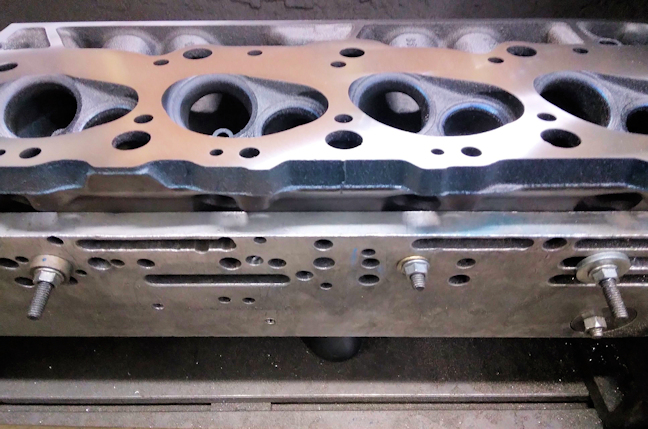

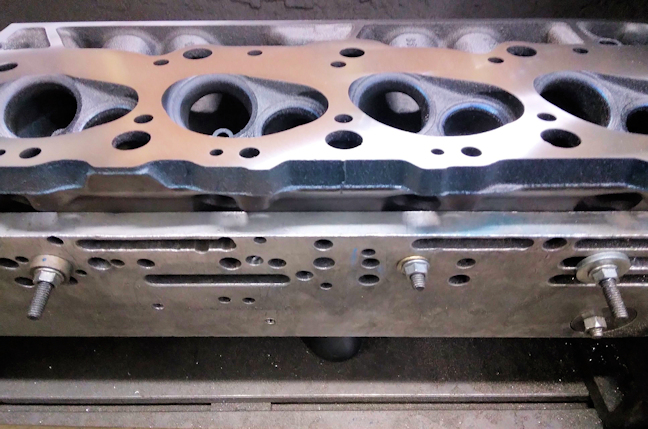

USE THOSE HOLES Most people use just the outer two bolt holes when fastening a cylinder head to a mounting fixture. If there are additional holes in the plate that line up with the threads in the fixture, then consider using the extra threads for increased rigidity. ...

by Donnie Hurt | Mar 1, 2022 | OPERATIONS

CATALOG SIX-PACK I know catalogs are online, but most of us would rather use paper catalogs. So, hang on to those old catalogs, because some companies are not printing them anymore. Our solution is to use beer boxes to file them. They are available for free at any...