by Donnie Hurt | Feb 1, 2022 | BLOCK WORK

DIALED IN When setting up a block for surfacing, depending on the machine used, it may not be possible to use the dial indicator that’s attached to the head of the surfacer (if there even is one). Creating a bar shaped like an L as pictured and mounting a cheap...

by Donnie Hurt | Feb 1, 2022 | CYLINDER HEADS

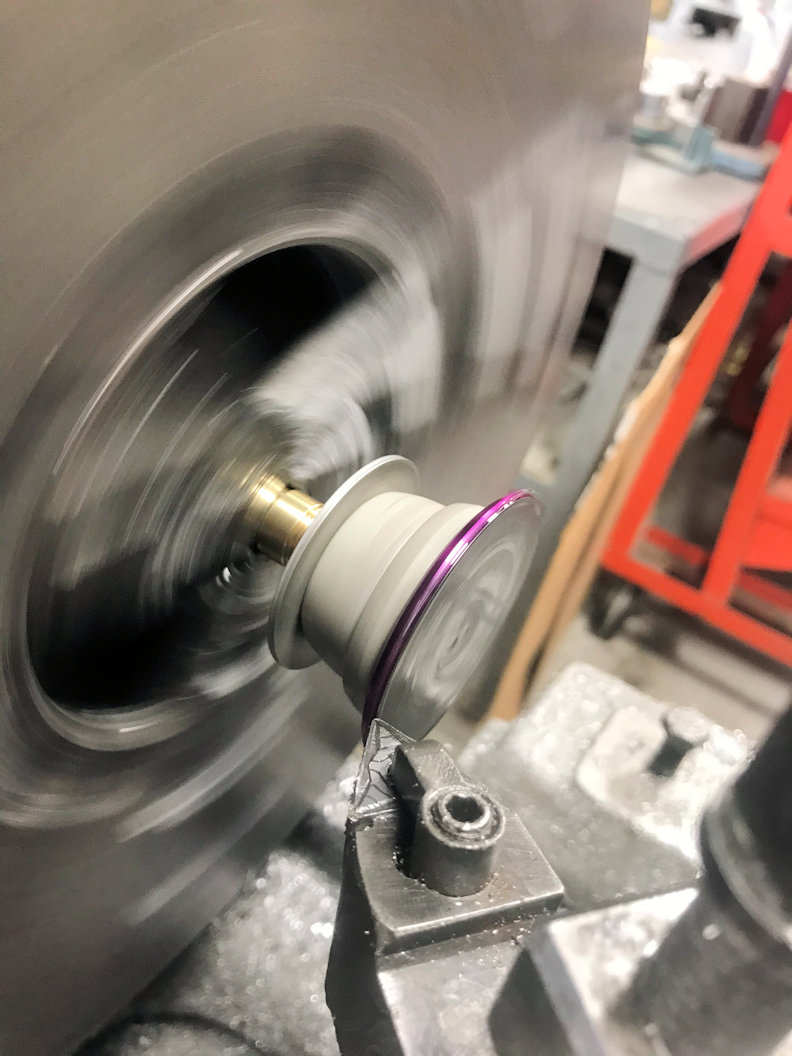

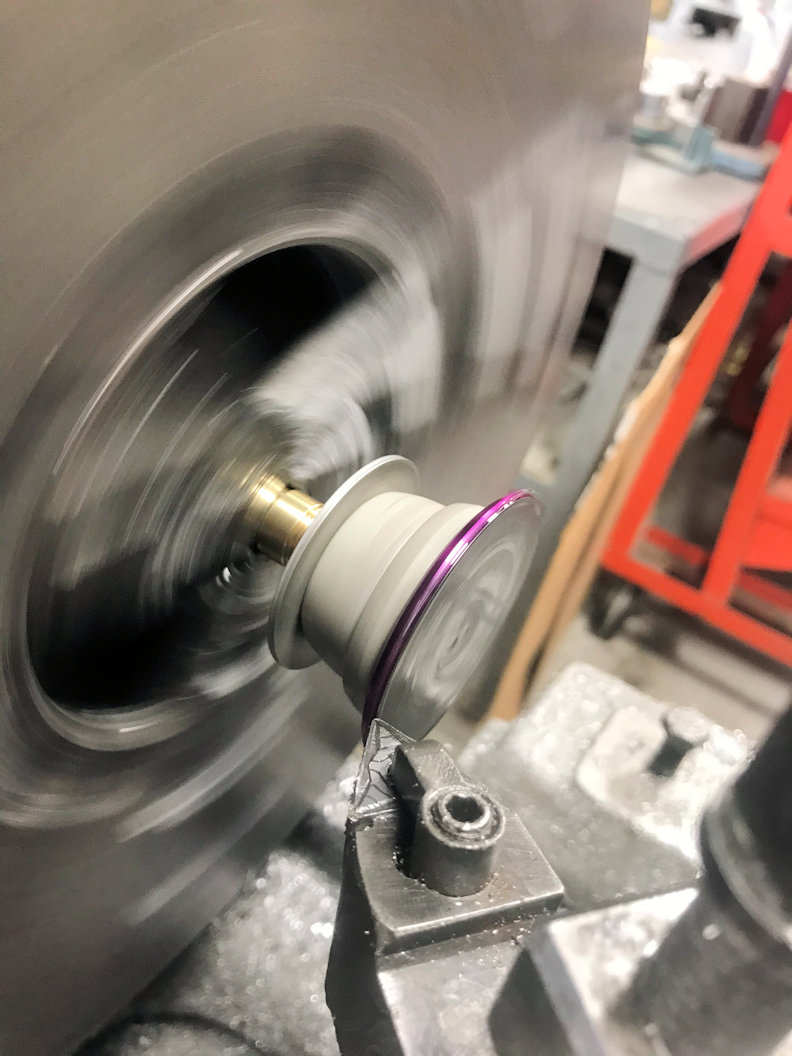

DOORSTOP DAMPER When cutting valve margins down, we use this simple rubber doorstop as a damper to help reduce chatter as we cut the face. We keep various size guides, and washers with it to clamp the valve in the lathe. Using the tail stock, you can press the valve...

by Donnie Hurt | Feb 1, 2022 | TOOLING

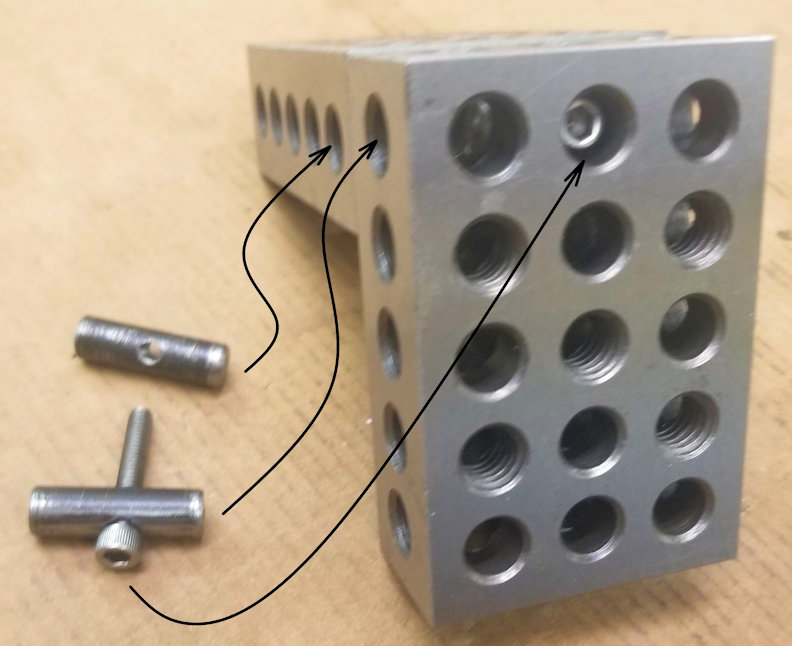

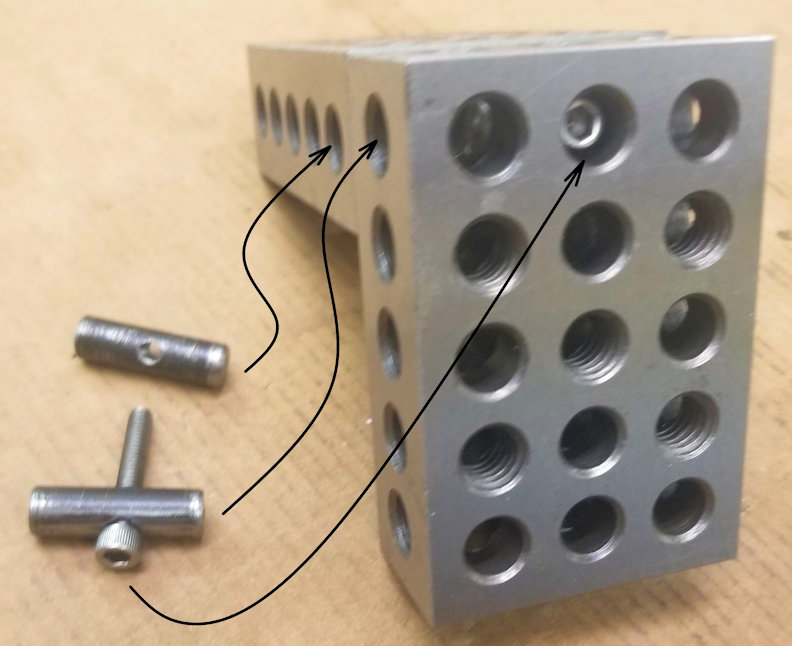

1-2-3 BLOCKING BUILDING Using 1-2-3 blocks to fixture manifolds or heads on a Bridgeport Mill may sometimes require joining a pair of 1-2-3 Blocks. While some 1-2-3 Blocks have a few threaded holes, these thread holes don’t always line up where needed. These...

by Donnie Hurt | Feb 1, 2022 | TOOLING

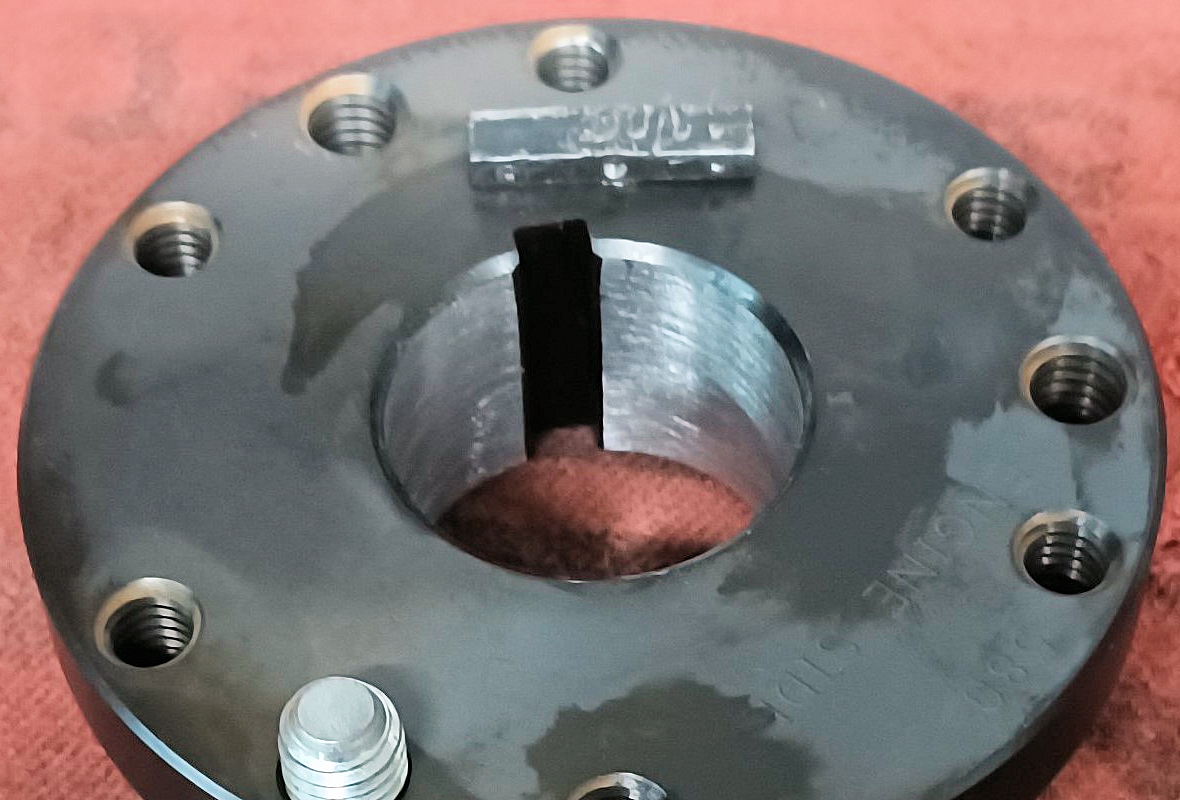

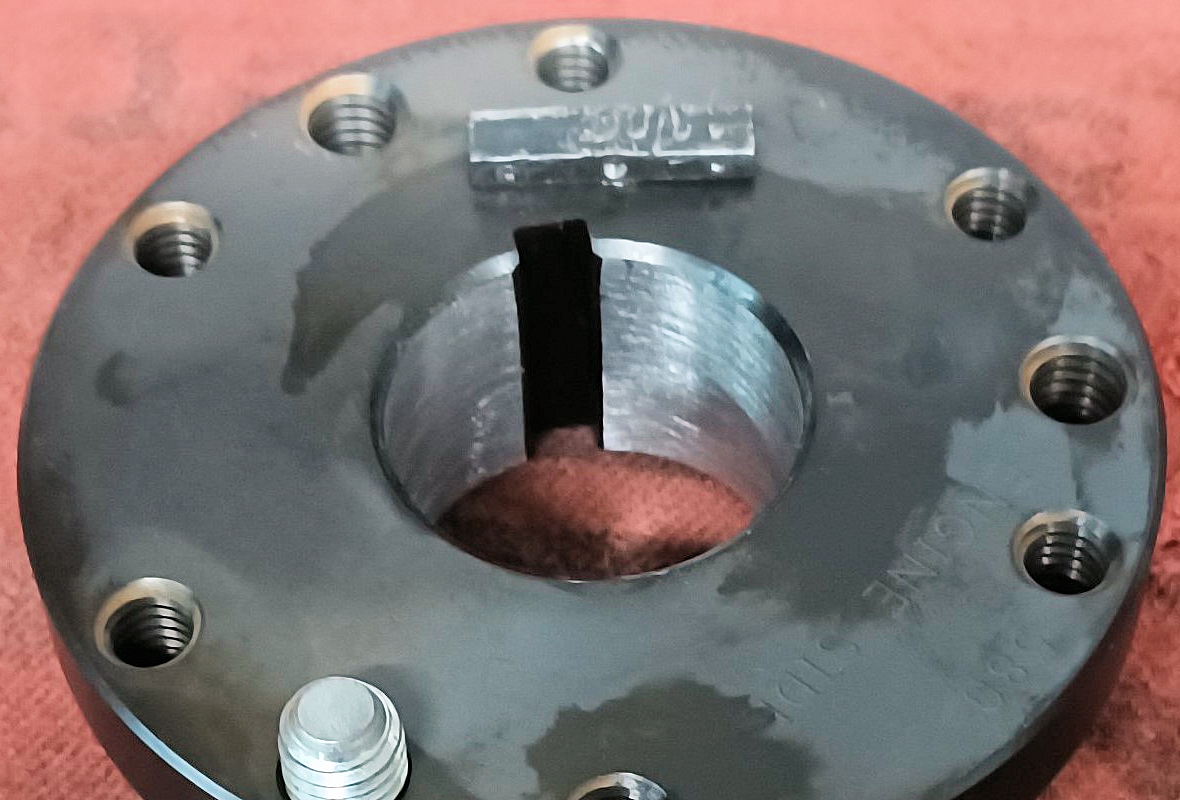

STICKY SITUATION This trick got me through a job that I didn’t have the correct tooling for. I don’t have a keyway rod hone mandrel in 1.375″ so I cut a piece of 1/4″ key stock in half to keep the shoes and stone on my mandrel from catching and...

by Donnie Hurt | Feb 1, 2022 | TOOLING

PROTECT YOUR INVESTMENT Whether you own a shop or work in a shop, take care of your investment in measuring tools. If you’ve ever damaged one you know what I mean. I always set them on shop rags in an old valve box while using them. They stay cleaner and...