by Donnie Hurt | Jan 1, 2022 | CRANKSHAFTS & CONNECTING RODS

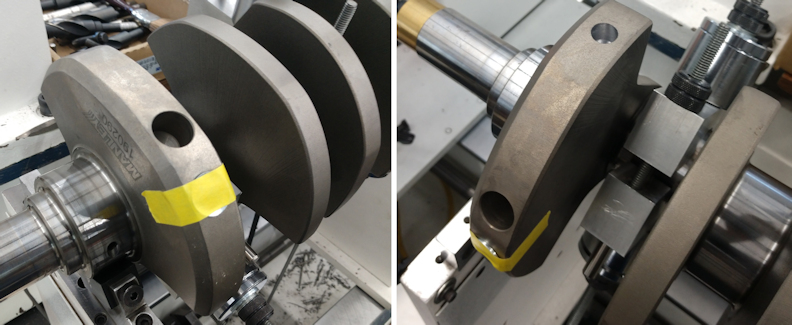

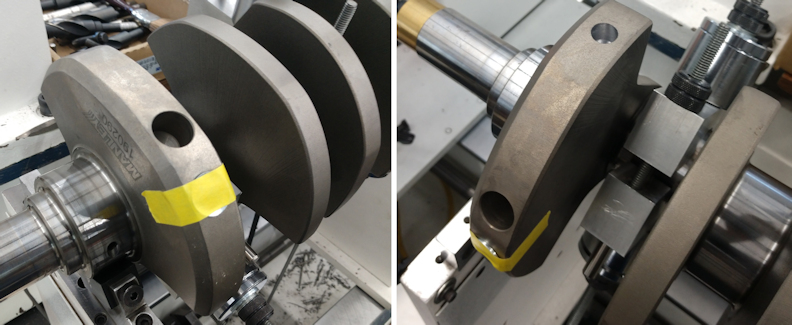

MOVE YOUR SPOT Sometimes when I first spin up a crank, the correction area is off the counterweight. Instead of grinding up by the rod throw, try adding weight to the opposite end if there are balance holes already. I taped in some flat disc plugs until the “spot”...

by Donnie Hurt | Dec 16, 2021 | NEW PRODUCTS

The team at Engine Parts Group brought several new products and additions to the catalog to this year’s PRI Show, including a series of multi-layer steel head gaskets for GM engines and a clever new windage tray for classic Chrysler engines. Read the whole story on...

by Donnie Hurt | Dec 1, 2021 | NEWS

Wheat Ridge, Colo.—Two automotive aftermarket suppliers were recently honored with performance awards by Engine Parts Group, Inc., also known as Engine Pro. The awards were announced at Engine Pro’s annual supplier meeting held in Dallas. Read the whole story on...

by Donnie Hurt | Dec 1, 2021 | TOOLING

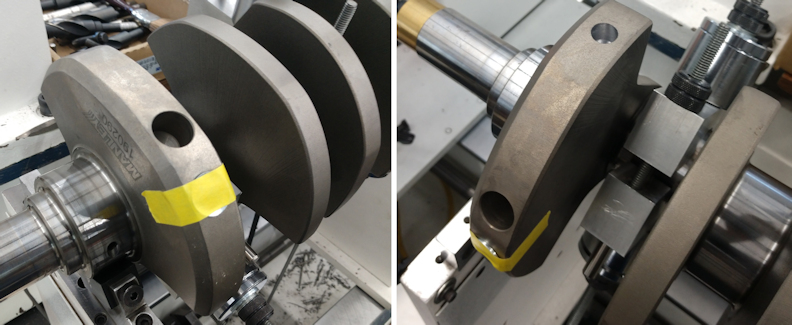

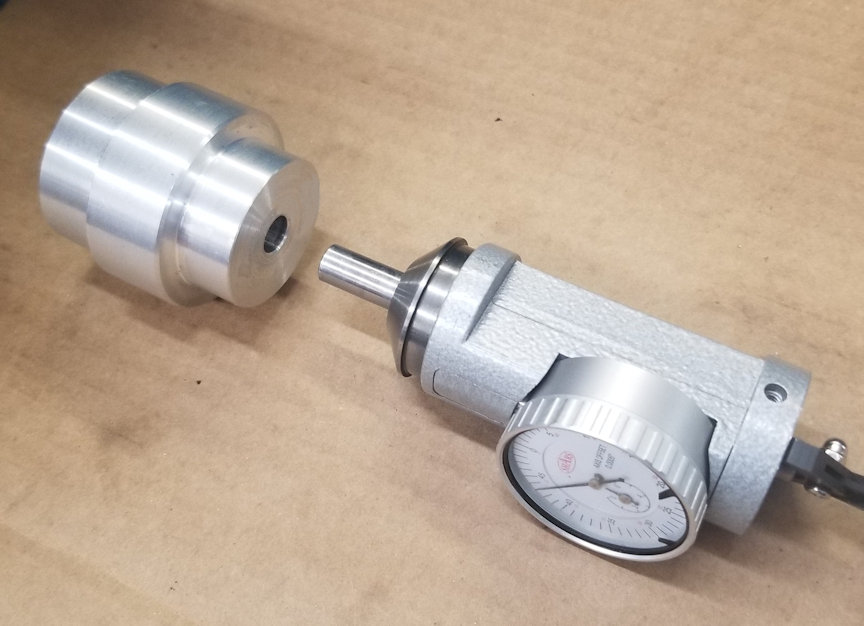

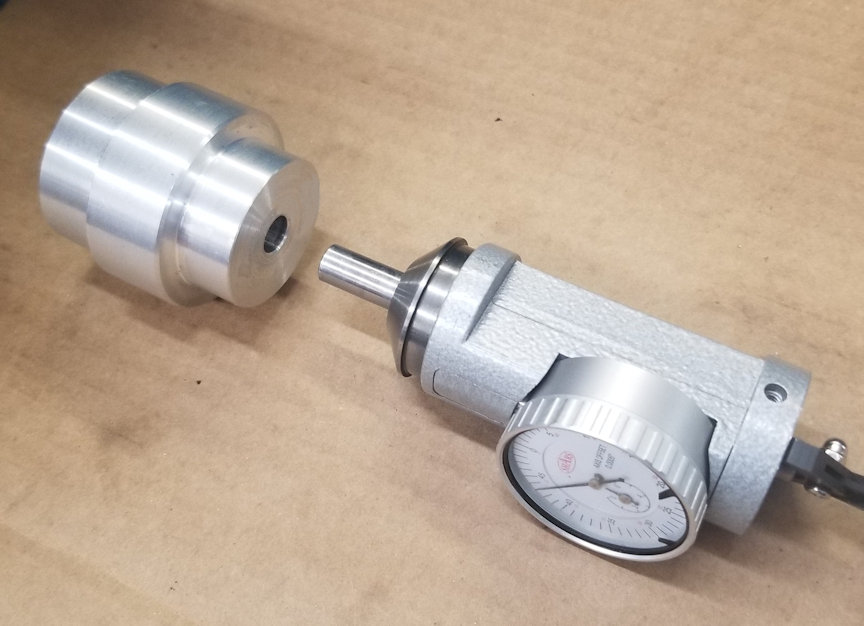

INDICATOR ADAPTER Most Co-Ax indicators have a 3/8″ or 1/2″ diameter stem. Instead of wasting time closing the lathe chuck to hold the indicator and then more time opening it back up to hold a larger diameter work piece, make a simple stepped adapter with...

by Donnie Hurt | Dec 1, 2021 | TOOLING

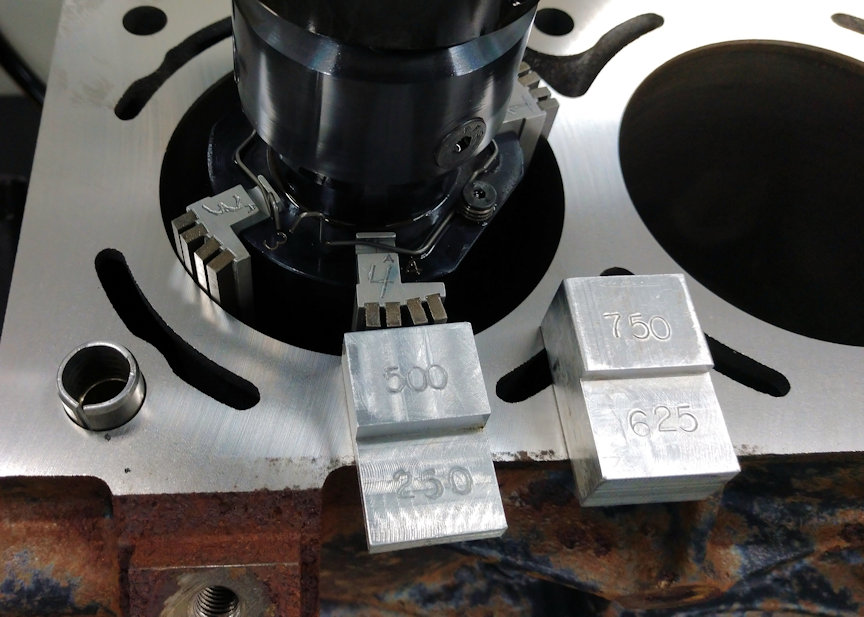

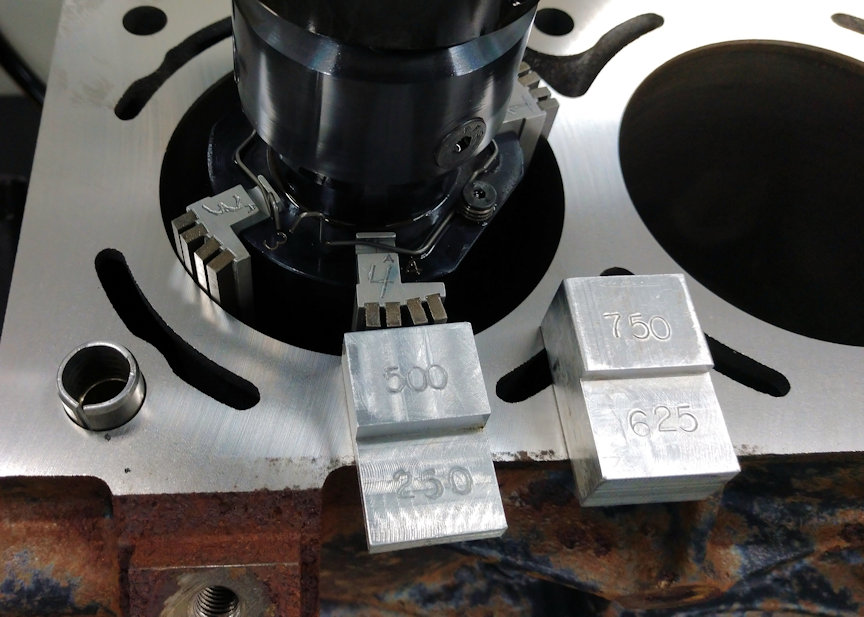

SET UP BLOCKS Keep your tape measure in the toolbox when doing set ups that you repeat time and time again. Make some gauge blocks or fixtures, whatever it takes to save time setting up your machines. Randy Torvinen Torvinen’s Machine Menahga, MN DECEMBER,...