by Donnie Hurt | Mar 1, 2021 | ASSEMBLY

STUD INSTALLER We use an old roller rocker arm adjuster nut and put a used rod bolt in place of the Allen jam bolt. I use this assembly to install main and head studs when they do not have a hex in them. Terry Dowker Dowker Engines Charlotte, MI MARCH,...

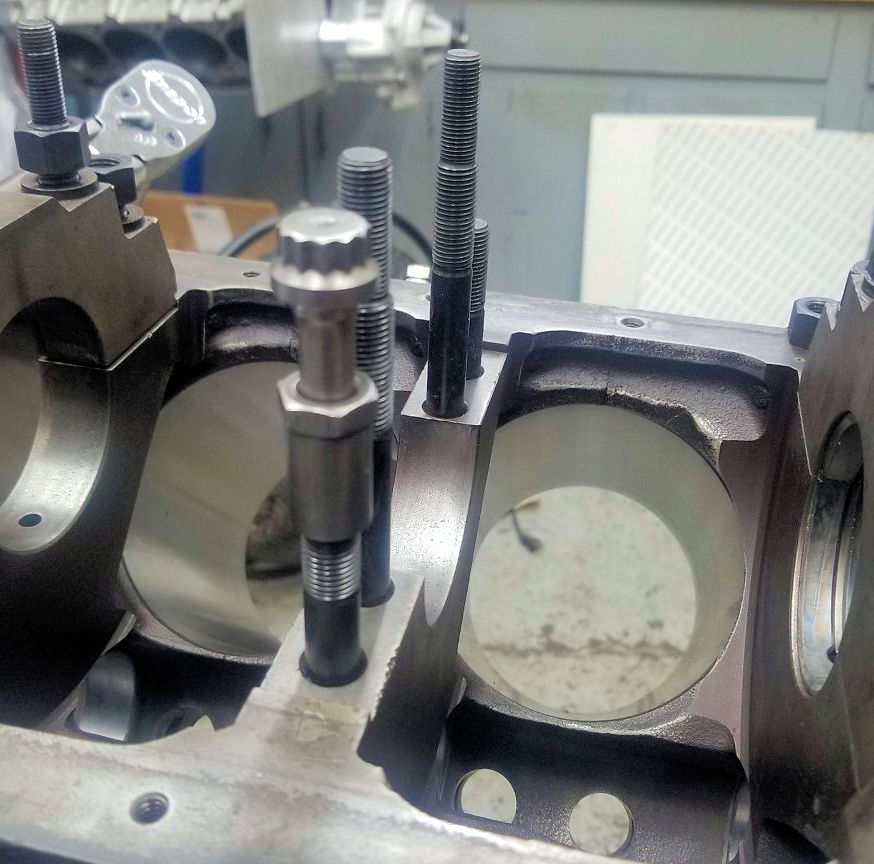

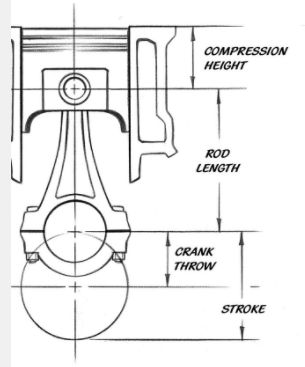

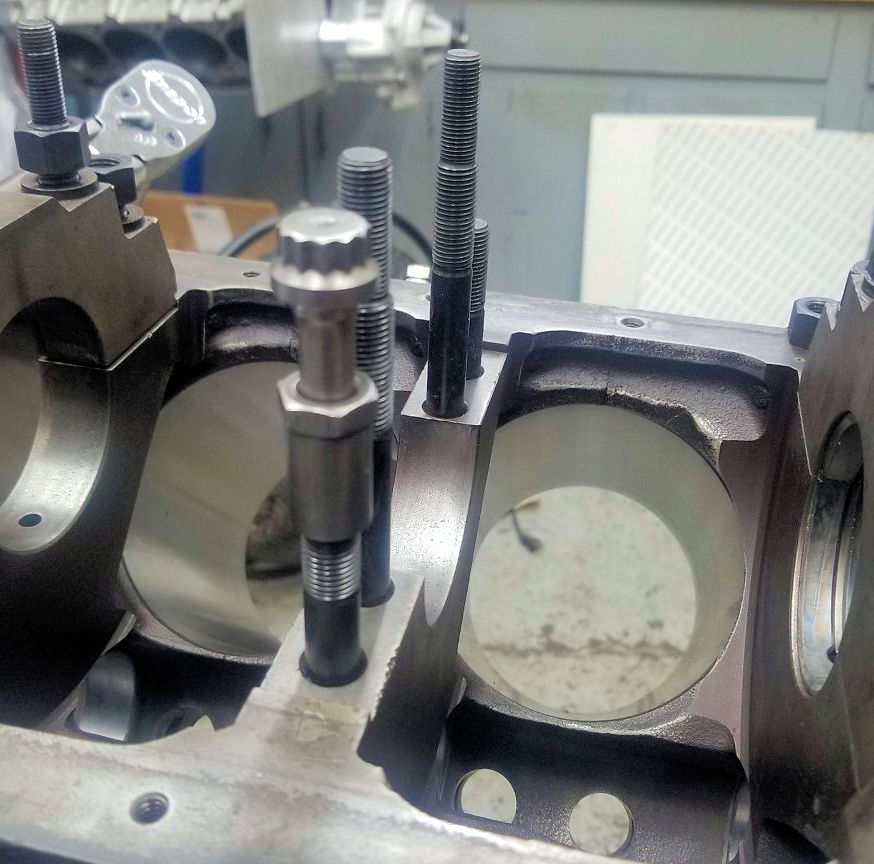

by Donnie Hurt | Mar 1, 2021 | BLOCK WORK

CAP MILLING I like to mill my main caps instead of grinding them, when possible. The milling process gets them very flat with accurate stock removal. This “Vice Adjuster” makes it quick to set tilt and I use a precision level along with an indicator to dial-in side to...

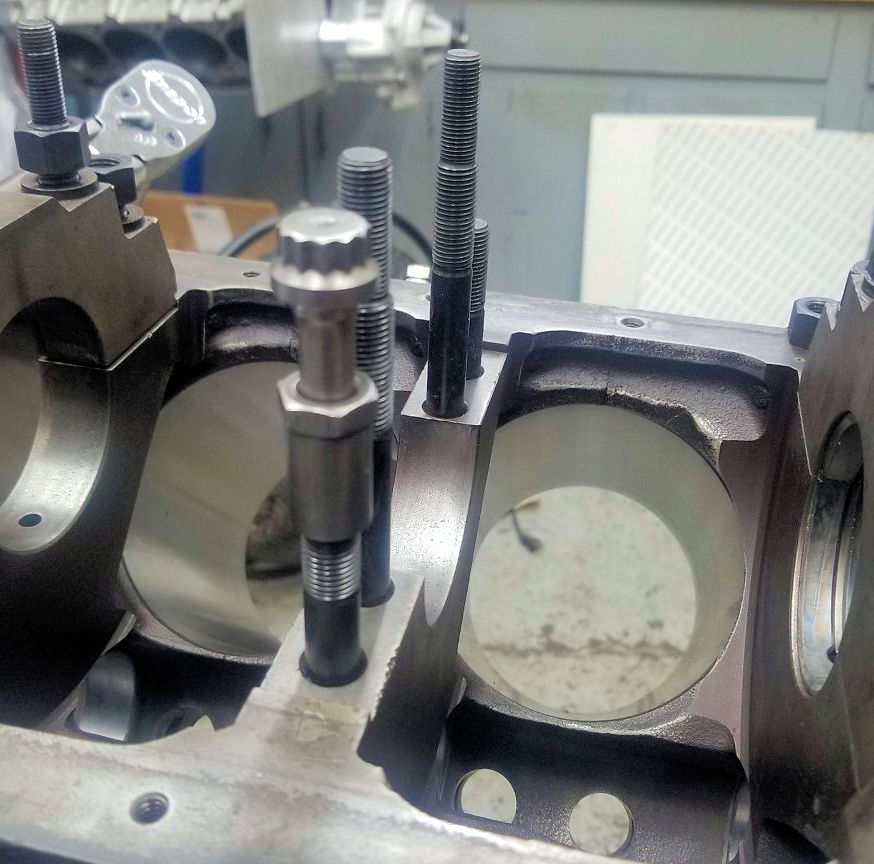

by Donnie Hurt | Mar 1, 2021 | OTHER SHOP WORK

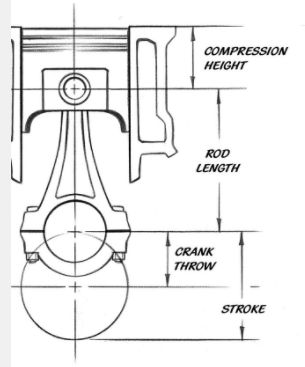

MAKE IT BIGGER Some engines are harder to increase the compression ratio on than others. Sometimes we are limited in cylinder head chamber size and sometimes higher compression pistons are not available or effective for certain engines. Increasing the crankshaft...

by Donnie Hurt | Mar 1, 2021 | CRANKSHAFTS & CONNECTING RODS

HEAVY METAL When adding heavy metal to crankshafts, you always want a nice clean installation. I start with a slightly heavier slug than required and machine the center of the tungsten like a barbell to bring the crank into balance, instead of running it short in the...

by Donnie Hurt | Feb 1, 2021 | CRANKSHAFTS & CONNECTING RODS

CRANK TURNING SOCKET I took a BB Chev crank socket and drilled and taped (3) ¼”-20 holes for set screws, 120 degrees apart. You can now use it on Mopar, Pontiac or just about any crankshaft with a 3/16” keyway. Paul Pionessa Pionessa Automotive Lancaster NY February,...