BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

UNDER PRESSURE

Feb 1, 2025 | BLOCK WORK, UNCATEGORIZED

On blocks and heads that have “suspect areas”, I have a “quick check” before I commit to bolting on the pressure test plates. I simply use my blow gun with a brake line attached, and blow air behind the questionable area, with some soap or bubble spray on the face...

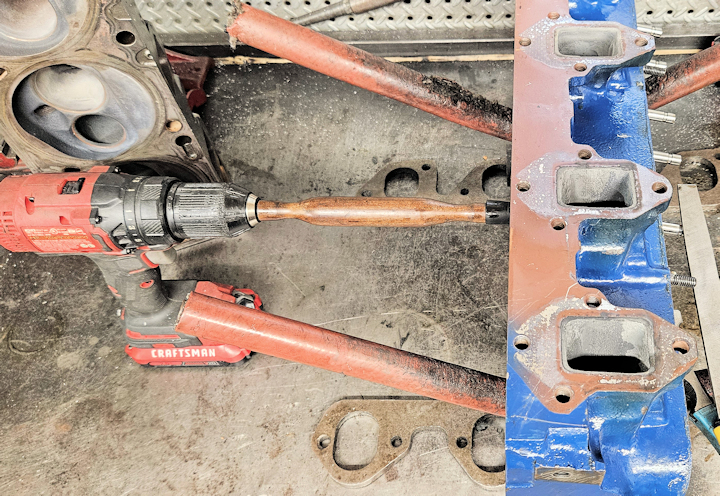

SPIN THEM UP

Feb 1, 2025 | CYLINDER HEADS

I had some FE heads with some pretty decent burrs on the valve tips. Instead of slowly turning the valves by hand to file the burrs off, I grabbed an old valve lapping stick and chucked it up in the drill to spin the valves. It went really quickly, and I was able to...

CLEANER HEATER

Feb 1, 2025 | DISASSEMBLY & CLEANING

My small ultrasonic parts cleaner heating element burned out. Rather than scrapping it, I just dropped an electric charcoal lighter in the solution. It heats up faster than before but, there’s no thermostat, so keep an eye on it. Scott Ouellette Powerplay Engine and...

DISHWASHER RACK

Jan 15, 2025 | DISASSEMBLY & CLEANING

A rack out of your wife's old dishwasher can make a great new home in your parts washer. Parts can be held apart by the tines, like keeping those precious fractured rods safe from dings. The silverware basket works great for smaller items. Josh Mitchell Mitchell...

SCRIBE NOTES

Jan 15, 2025 | CYLINDER HEADS

On race engine cylinder heads that have exotic seat angles, I like to leave myself notes for future reference on freshen ups. I do keep a lot of notes in my folders and build sheets, but I found it handy to scribe the valve seat angles under the cylinder heads (kind...

CHECKING CAM BEARING HOUSING BORES

Jan 15, 2025 | BLOCK WORK

After assembling over 5,000 engines, I have seen just about every conceivable problem that can arise during engine assembly. One particular area of concern was the cam bearing housing bore size in all engines, particularly Ford small block and big block engines,...