BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

TAKING CAM BREAK IN SERIOUSLY

Oct 6, 2025 | CAMSHAFTS & VALVE TRAIN

When breaking in flat tappet cams, I place these Rare Earth Magnets on the top of the outer head bolts, and I'll use break-in rocker arms when the open pressure is high. These and a magnet on the drain plug let me keep an immediate eye on ferrous metal, and I send off...

CRANK DRIVEN PUMP TEST

Oct 1, 2025 | LUBRICATION & COOLING, TOOLING

It's hard to trust many parts today. We've seen new oil pumps with issues right out of the box. We always take them apart to clean and inspect, lube up the pressure relief valve, and put them back together. Old style shaft driven pumps are pretty easy to bench test,...

CRANKSHAFT TURNING ADAPTOR

Oct 1, 2025 | TOOLING

To turn a small block Chevy crank with the damper on, I cut off an old crank snout and remove a few thousandths from the diameter so it would slide inside the damper. Than I can use it along with my crank-turning socket. Sylvain Tremblay Les Ateliers de Moteur...

SECONDARY RETENTION

Sep 22, 2025 | CRANKSHAFTS & CONNECTING RODS

If you find yourself having to fill a counterweight hole when balancing, here’s a tip. Once your piece of metal is installed, drill and tap for a tapered crack repair plug, as a secondary retention procedure. This, along with the press fit, gives you absolute...

MILLING HACKS

Sep 15, 2025 | OTHER SHOP WORK

Here are three simple CNC milling hacks. 1.) Slip a zip-lock bag over a dripping coolant nozzle while loading and unloading a part or cleaning up the machine. This’ll save you some aggravation. 2.) Secure floppy C-clamp handles with a rubber band to save time, and a...

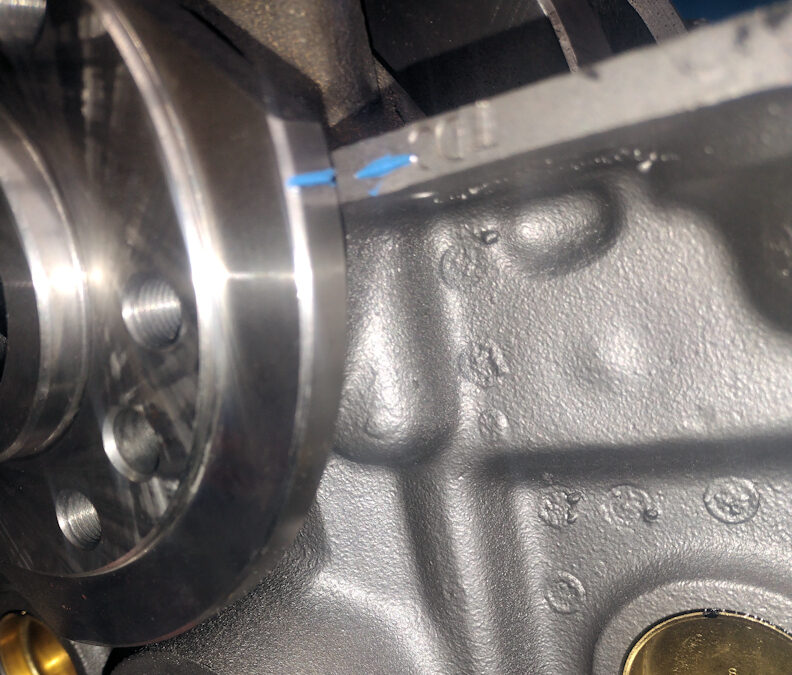

REAR TDC MARK

Sep 8, 2025 | ASSEMBLY

After I have established true TDC and I’m getting ready to degree my camshaft, I will take a sharp chisel and put a small mark on the back of the block and the crank. It helps to find TDC in the future should someone slip a balancer or change something up, causing us...