BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

BROACHING THE SUBJECT

May 1, 2021 | OTHER SHOP WORK

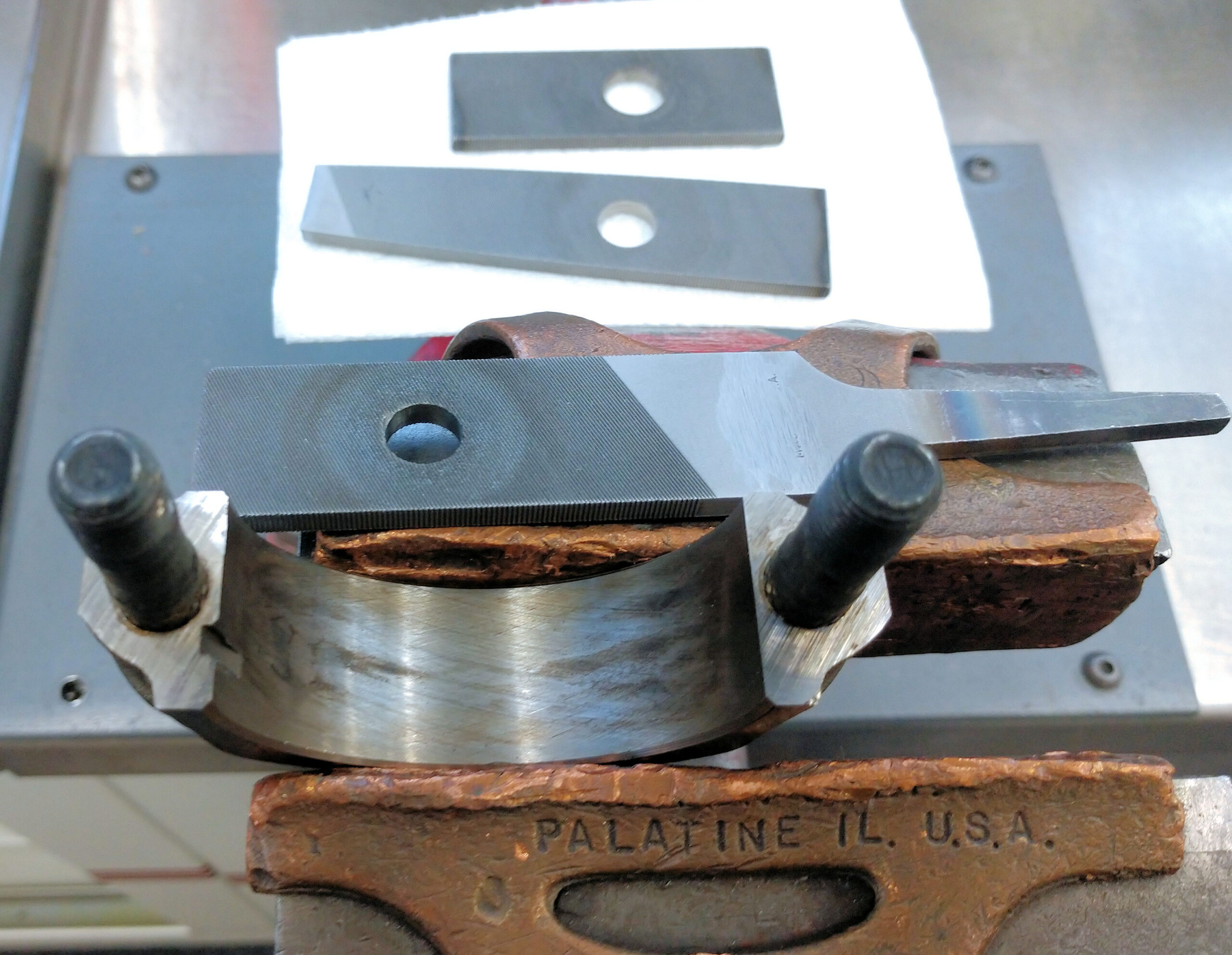

BROACHING THE SUBJECT When broaching a keyway in a relatively thin part, such as this modified gear cut from a Chevy camshaft or a narrow pulley, I use an aluminum spacer to hold the broach guide bushing up and out of the work piece. This will help hold the broach...

EASY ROD DEBURR

May 1, 2021 | CRANKSHAFTS & CONNECTING RODS

EASY ROD DEBURR I have an easy way to deburr a connecting rod with the bolt still in and even performance rods with the dowels in. I had some file pieces drilled by my buddy at a tool shop. He drilled them about .005 over with Carbide drills. I have 3/8”, 7/16” and ½”...

ANOTHER SILLY HEAT TRICK

Apr 1, 2021 | DISASSEMBLY & CLEANING

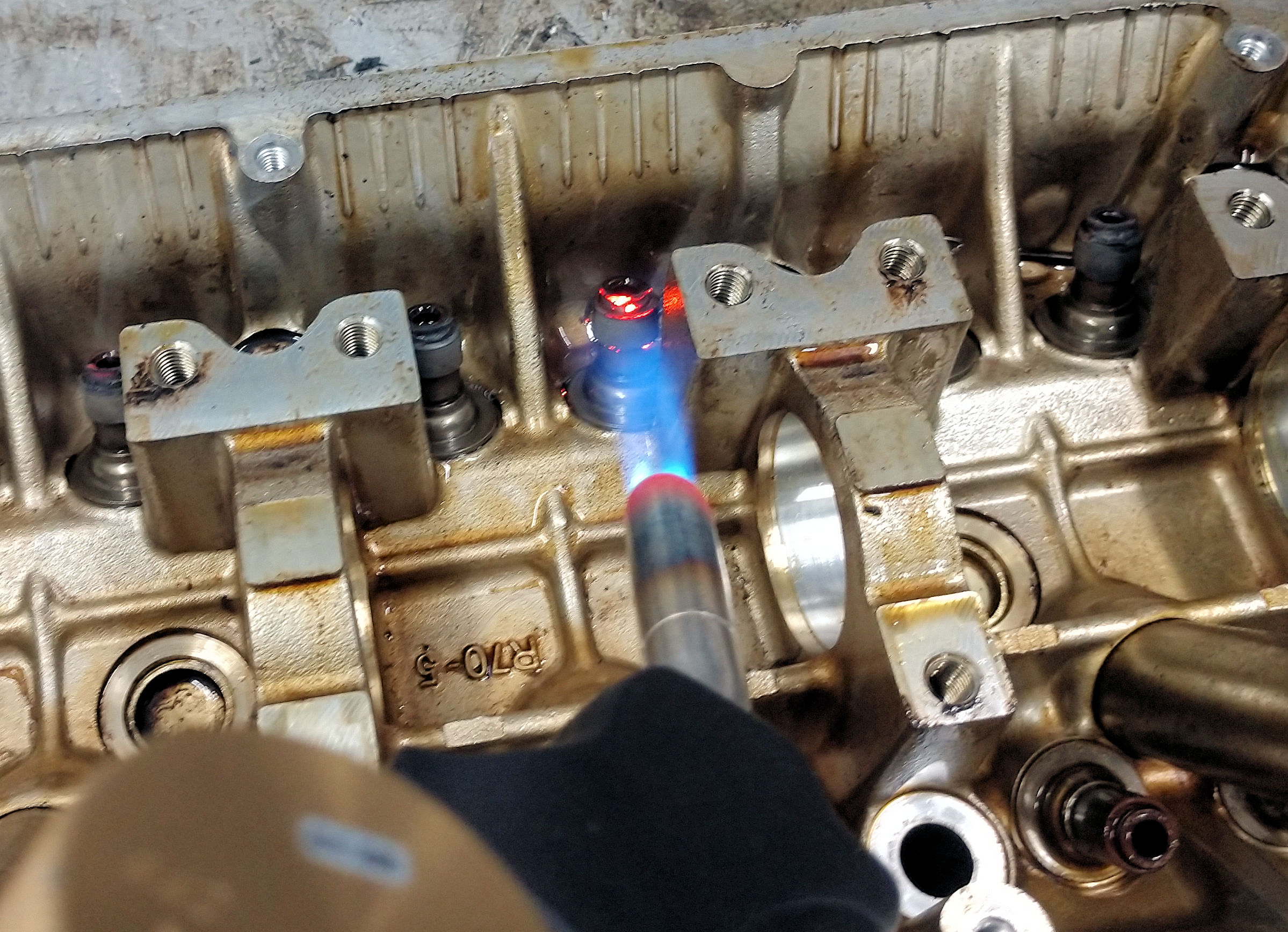

ANOTHER SILLY HEAT TRICK We all heat our oil plugs, studs and bolts to free them up. I found another heat solution, removing stubborn valve seals. I just warm them up with a propane torch to soften the rubber and they pull right off. This works great! Randy Torvinen...

A DIFFERENT CAM BEARING FIT

Apr 1, 2021 | BLOCK WORK

A DIFFERENT CAM BEARING FIT Most if not all OEM blocks were fitted with semi-finished cam bearings and then the I.D.”s were bored in place. Many suffer from poor factory size issues. This situation can lead to tight or no bearing clearance when finished cam bearings...

MEASURE ONCE, CUT TWICE

Apr 1, 2021 | OPERATIONS

MEASURE ONCE, CUT TWICE Yes, we’ve all made that mistake, measure once and you better hope you cut it long, so the second cut will be on spec. Otherwise you’ve ruined the work. The proper phrase, measure twice… seems to apply to many things we do around the shop. ...

SIGHTING IN YOUR CAM BEARINGS

Apr 1, 2021 | BLOCK WORK

SIGHTING IN YOUR CAM BEARINGS We all know that some cam bearings can be a bear to install with their holes lining up correctly. To help ease the installation, we milled a .125” slot down the center of our cam bearings tool. By aligning the hole in the bearing with the...