BROWSE BY CATEGORY

BROWSE ALL SHOP SOLUTIONS

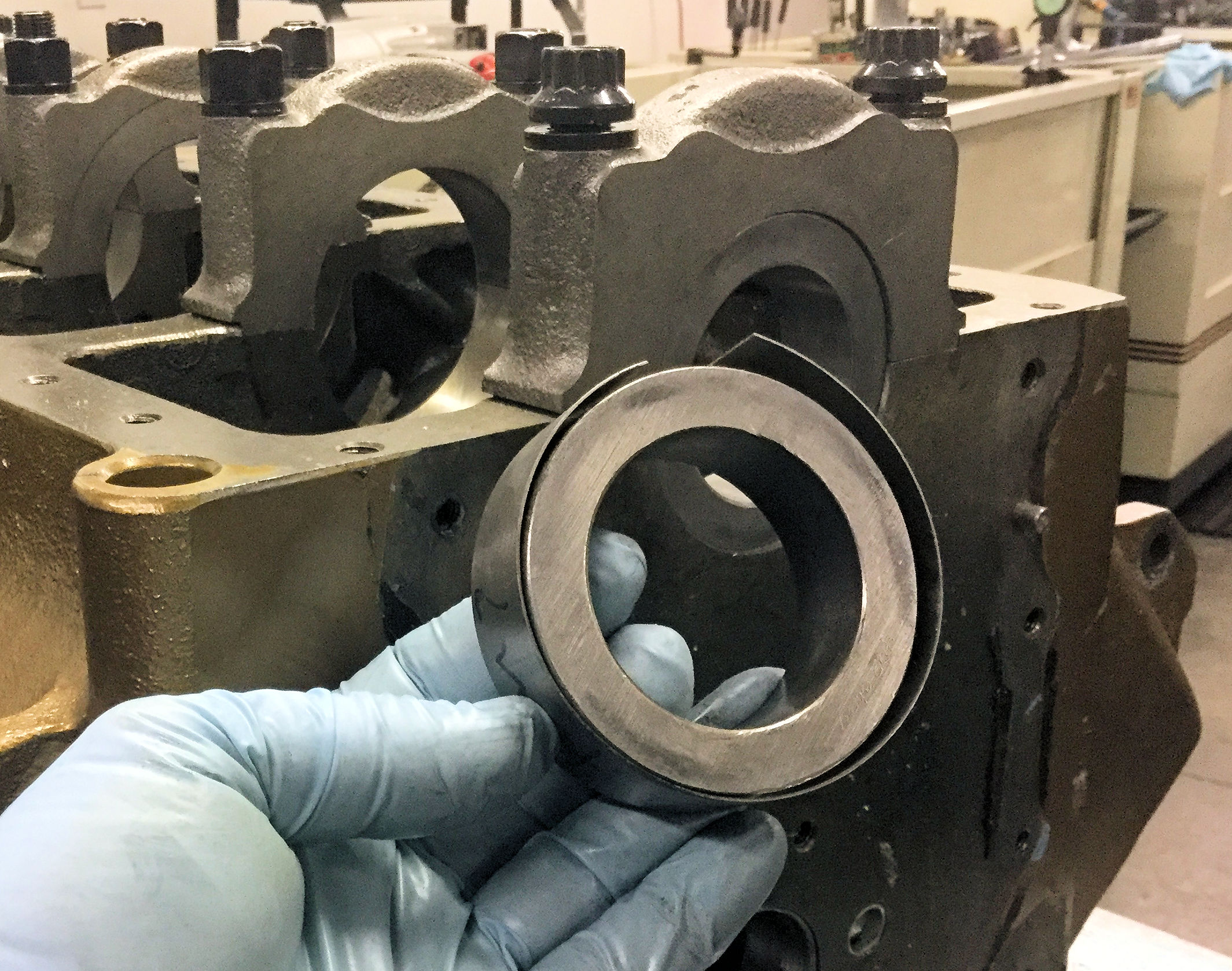

MAIN RING CHEAT

Apr 1, 2020 | BLOCK WORK

MAIN RING CHEAT On some blocks that you may not have Main Bar Rings for there is often one that is very close to one you do have. I simply make precision spacers from shim stock and run them through slip roll to make them round. For example, the 400 Chevy ring plus a...

YOUR BIGGEST FAN

Apr 1, 2020 | OTHER SHOP WORK

YOUR BIGGEST FAN We made our drum fans serve a dual purpose. There are no more 12-volt fans with switches and wiring for our engine test stand. Do you need to change a cam or fix a timing cover leak? Just roll the fan/radiator assembly out of the way to make your...

EXPANDING PLUGS

Apr 1, 2020 | ASSEMBLY

EXPANDING PLUGS When I find the need for a little more press on a cup expansion plug I use a modified spring retainer with a taper to lightly expand them in the press. Randy Torvinen Torvinen’s Machine Manahga, MN April, 2020

MANDREL FOR MACHINING OLD RETAINERS

Mar 1, 2020 | CYLINDER HEADS

MANDREL FOR MACHINING OLD RETAINERS I had a different combination of valve stem and spring diameters to work with and I could not find spring retainers to fit. I had previously made these mandrels to hold and modify 7° & 10° retainers, so this job was easy to...

ORGANIZATION FOR EFFICIENCY

Mar 1, 2020 | TOOLING

ORGANIZATION FOR EFFICIENCY I’ve found “1-Buck” store mini muffin tins are great inexpensive parts organizers. I use them for bucket style solid lifters that are found in many late model DOHC heads. They enable me to easily put them back in the original positions. In...

INNER TUBULAR

Mar 1, 2020 | CAMSHAFTS & VALVE TRAIN

INNER TUBULAR For the past 20 years, I have been buying bicycle inner tubes at the local hardware store to replace the neoprene sleeve on our universal cam bearing tool. The inner tube costs range from $5.99-9.99 and will give you more bang for the buck. Cut the inner...