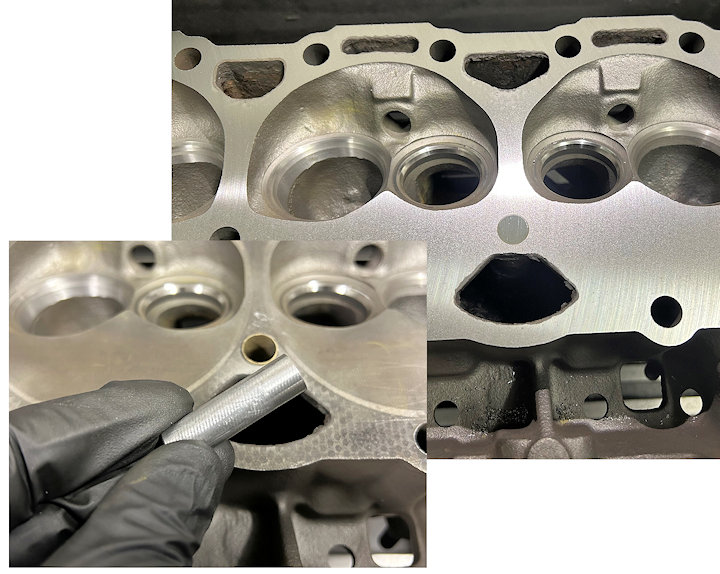

by Donnie Hurt | Dec 9, 2025 | CYLINDER HEADS

When surfacing heads that have had brass tubes installed in head bolt or pushrod holes, I slip snug aluminum plugs in the tube to support them while cutting. This prevents the cutter bit from grabbing the tube and folding inward. This works great on any application...

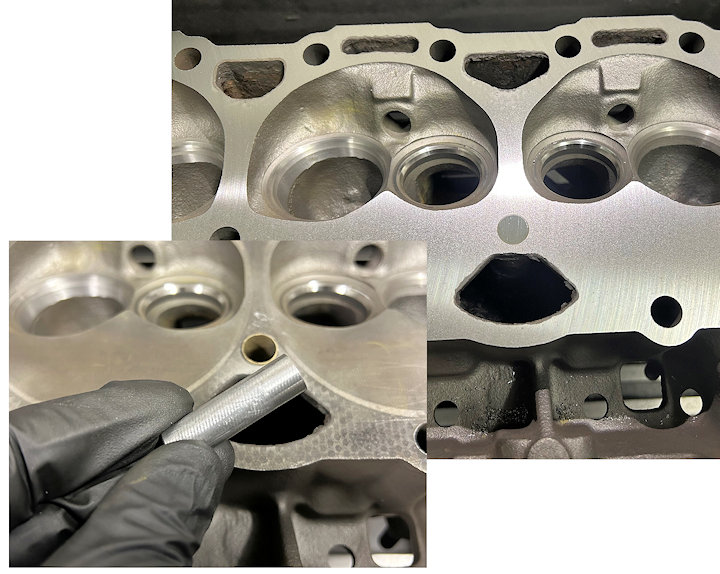

by Donnie Hurt | Aug 1, 2025 | CYLINDER HEADS

We just modified a Lisle keeper removal tool to help with multi-groove keepers. I had to turn down the top on the lathe so it would fit into a ¾” collet. The hammer method doesn’t work well on 3 and 4-groove applications, and it’s not fun trying to...

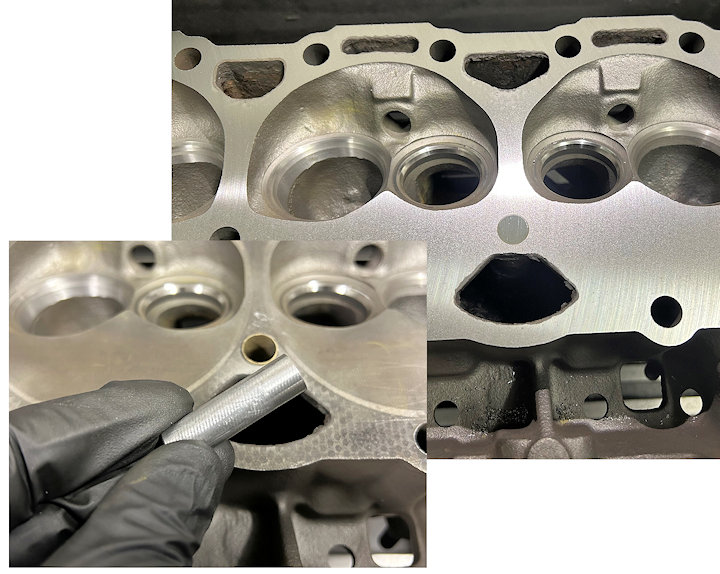

by Donnie Hurt | Jul 21, 2025 | CYLINDER HEADS

Over the years we’ve all had to do screw-in stud conversions on small block Chevs. I made up a pilot by milling flats to fit the pushrod slot width and turned two different diameters to fit the two slot lengths they have. I used a 7/16 rod and milled the flat...

by Donnie Hurt | Jun 4, 2025 | CYLINDER HEADS, UNCATEGORIZED

The person who taught me to broach bronze liners used hose clamps, but sometimes they crack. More often it’s when it has had a .502” service guide installed. So instead of hose clamps, I bought some inexpensive split collars for 1/2″. A person could machine them...

by Donnie Hurt | Jan 15, 2025 | CYLINDER HEADS

On race engine cylinder heads that have exotic seat angles, I like to leave myself notes for future reference on freshen ups. I do keep a lot of notes in my folders and build sheets, but I found it handy to scribe the valve seat angles under the cylinder heads (kind...