by Donnie Hurt | Dec 23, 2024 | CRANKSHAFTS & CONNECTING RODS

When checking and correcting rod straightness, I use two bars against each other in the rod vice. Since the vice isn’t mounted to the cabinet strong enough for most correction work, this allows you to use it. I feel the two bars gives me a better feel for how much I’m...

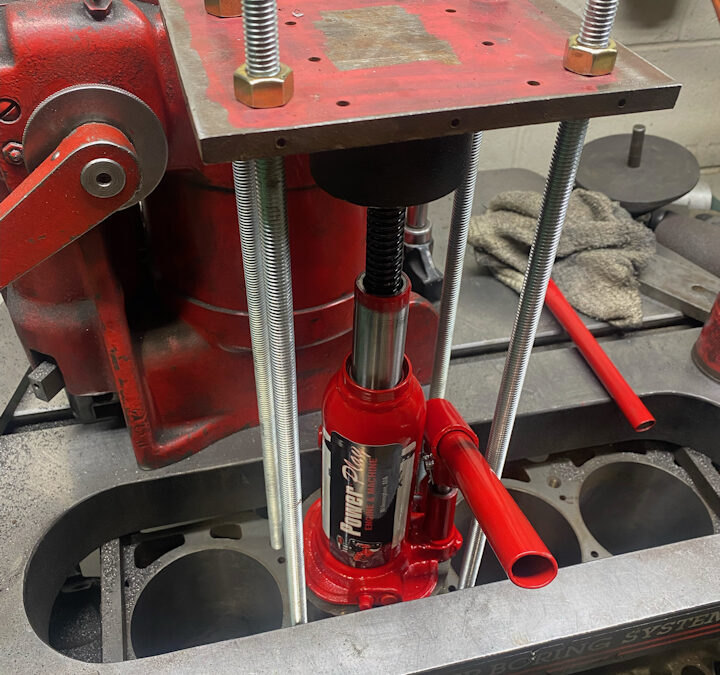

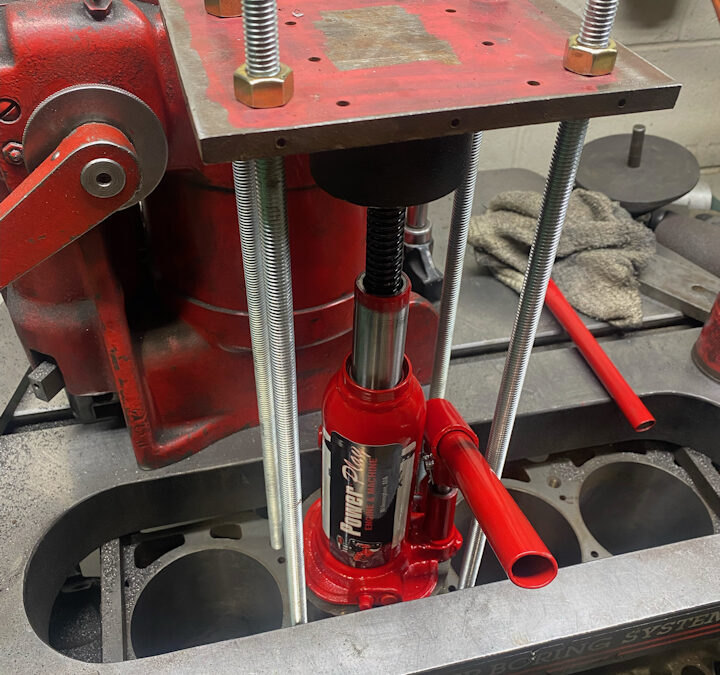

by Donnie Hurt | Dec 18, 2024 | BLOCK WORK

Instead of hammering sleeves in, I made this fixture out of a small bottle jack, threaded rod, and a steel plate. Once the plate is drilled for different blocks it makes the job super-fast, and my arm isn’t sore from swinging the hammer.

by Donnie Hurt | Oct 11, 2024 | OTHER SHOP WORK

Sometimes, we get those cores in the shop where someone had previously attempted to drill out a broken fastener, and they wander way off-center. We often need to install a larger repair insert than we normally would. I like to use a piloted counterbore cutter to drill...

by Donnie Hurt | Oct 8, 2024 | OTHER SHOP WORK

When you need to make a thread repair, and someone has “borrowed” your tap drill size chart, here is a little trick. Subtracting the pitch from the nominal thread O.D. will get you very close to the tap drill size for a 75% thread. Here are some examples:...