by Donnie Hurt | Apr 15, 2025 | BLOCK WORK

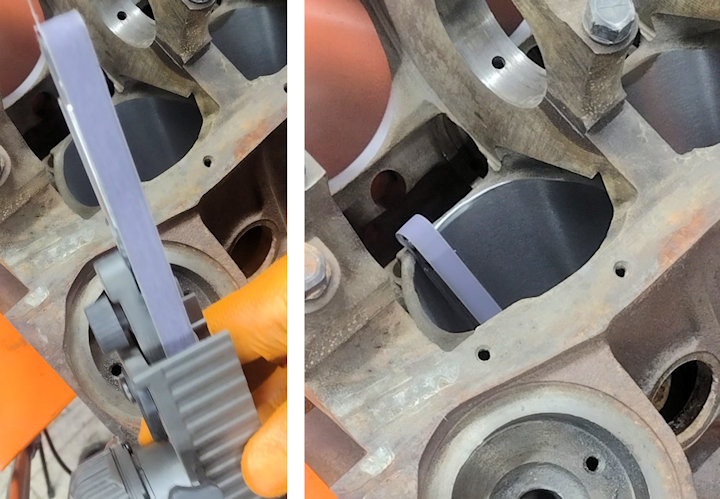

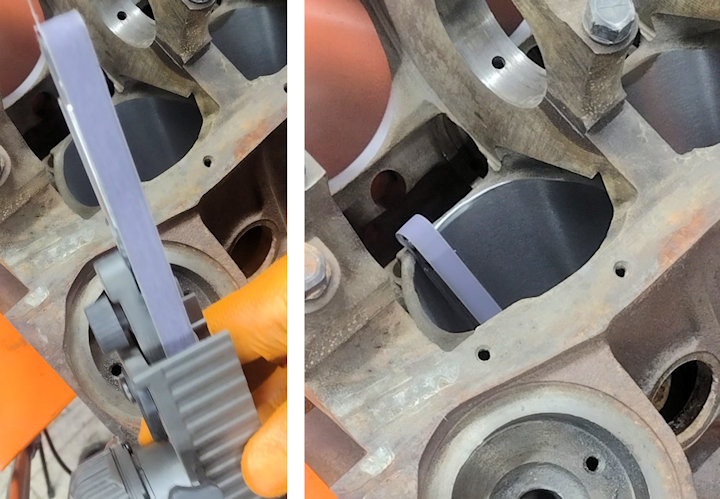

Freshly bored blocks leave a sharp edge on the bottom where the skirts protrude. I’ve found one of these little belt sanders are perfect to break that edge and add a chamfer. The outboard side I do from the crankcase and the Inboard side I put the sander through...

by Donnie Hurt | Apr 1, 2025 | BLOCK WORK

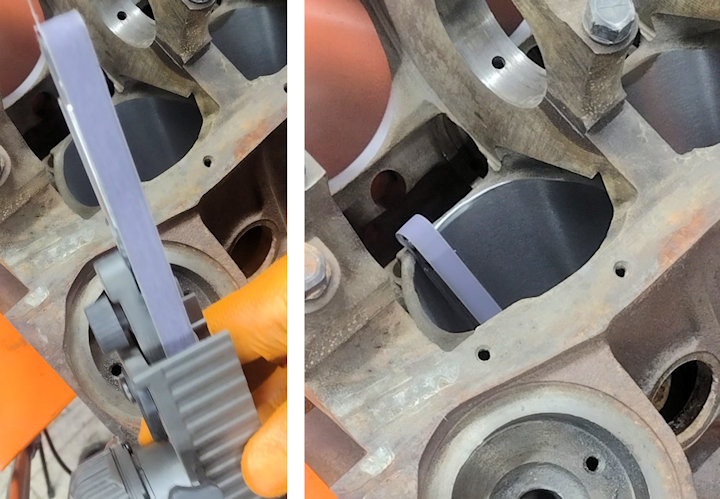

Sometimes when chasing the head bolt holes on Chevy blocks, you’ll hit a casting knob. Then you think, will the bolt thread in far enough. I use a 7/16 valve guide and some washers to mimic the cylinder head thickness. This saves time by not having to measure...

by Donnie Hurt | Mar 4, 2025 | GASKETS & SEALING

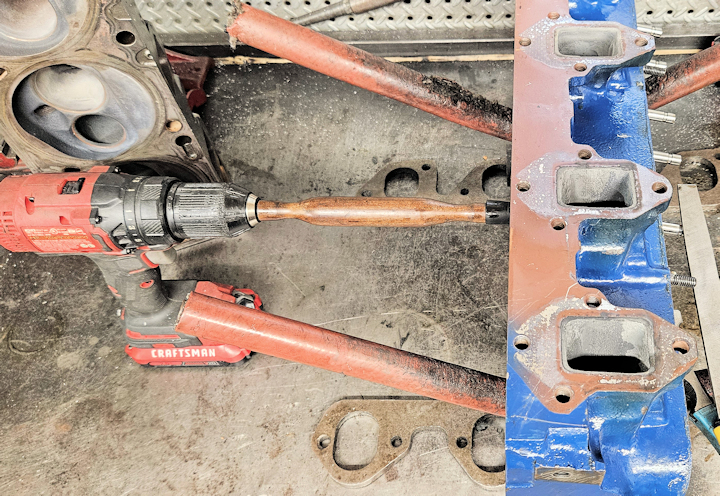

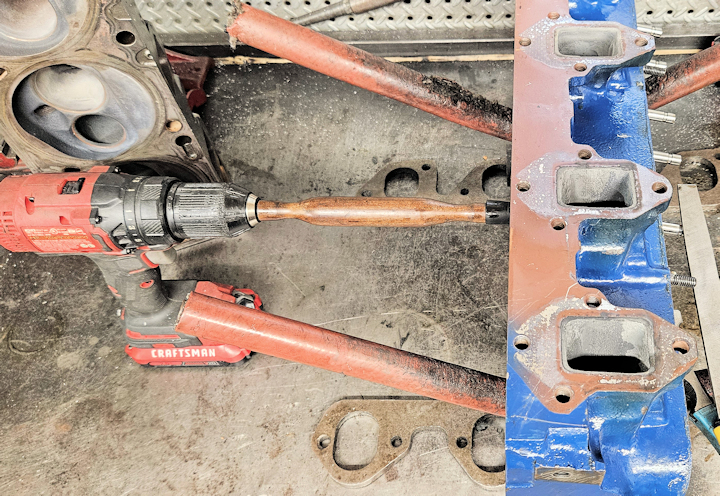

When deciding how much to mill an intake manifold for “fit”, I use cardboard shims. Most gaskets are .060 compressed, and if the intake fits great with, say, a .020 shim, then a .040 removal is needed. At that point, I also check the ends for fit. Machine once, wash...

by Donnie Hurt | Feb 1, 2025 | BLOCK WORK, UNCATEGORIZED

On blocks and heads that have “suspect areas”, I have a “quick check” before I commit to bolting on the pressure test plates. I simply use my blow gun with a brake line attached, and blow air behind the questionable area, with some soap or bubble spray on the face...

by Donnie Hurt | Feb 1, 2025 | CYLINDER HEADS

I had some FE heads with some pretty decent burrs on the valve tips. Instead of slowly turning the valves by hand to file the burrs off, I grabbed an old valve lapping stick and chucked it up in the drill to spin the valves. It went really quickly, and I was able to...