by Donnie Hurt | Oct 6, 2025 | OTHER SHOP WORK

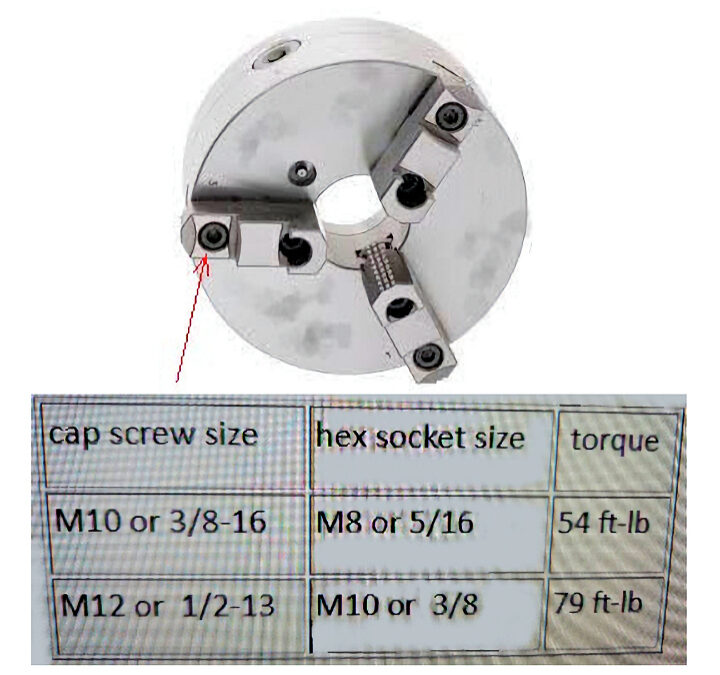

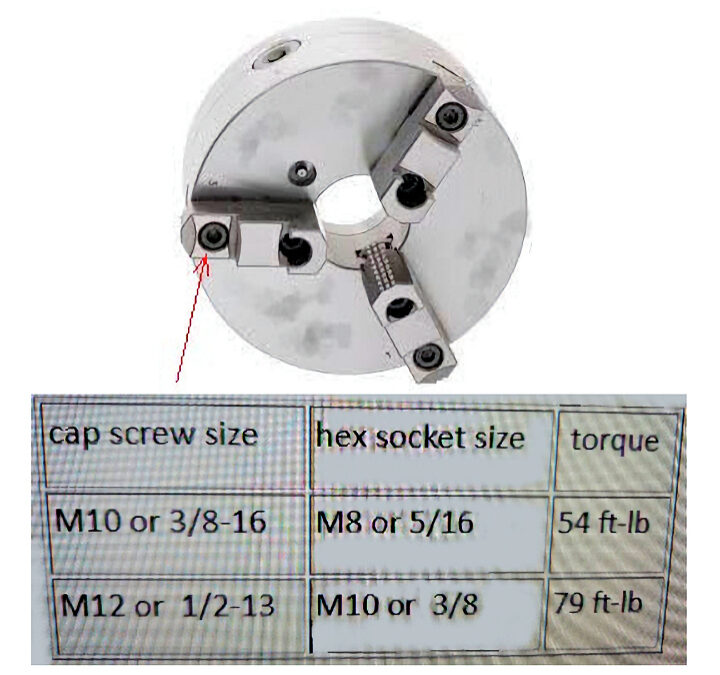

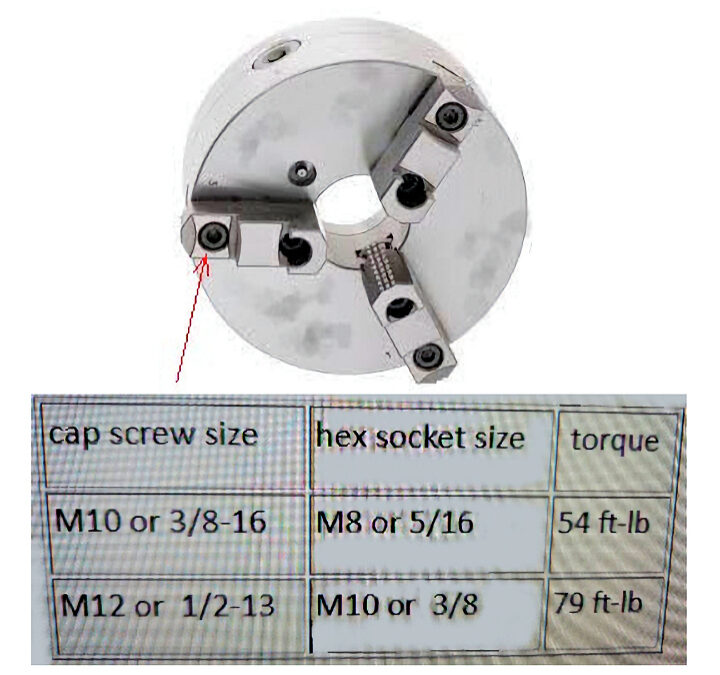

A small reduction of run-out on lathe or crankshaft grinder chucks, with bolt on top jaws, can often be achieved by an even torque of the socket head cap screws that attach the top jaws. I’ve included the proper torque, by cap screw size, for the more common American...

by Donnie Hurt | Oct 1, 2025 | TOOLING

To turn a small block Chevy crank with the damper on, I cut off an old crank snout and remove a few thousandths from the diameter so it would slide inside the damper. Than I can use it along with my crank-turning socket. Sylvain Tremblay Les Ateliers de Moteur...

by Donnie Hurt | Sep 15, 2025 | OTHER SHOP WORK

Here are three simple CNC milling hacks. 1.) Slip a zip-lock bag over a dripping coolant nozzle while loading and unloading a part or cleaning up the machine. This’ll save you some aggravation. 2.) Secure floppy C-clamp handles with a rubber band to save time, and a...

by Donnie Hurt | Sep 8, 2025 | CRANKSHAFTS & CONNECTING RODS

I hone the I.D. of an old harmonic balancer to slide on the crank, so it works as a stabilizer when removing and installing tone wheels. Arus Kinney AK’s Engine and Machining Covington, GA

by Donnie Hurt | Sep 2, 2025 | CRANKSHAFTS & CONNECTING RODS

A guy can’t buy everything so when a new type of tapered bushing connecting rod comes in, I make my own installer. It’s easy enough to remove the old bushing with an appropriate size bushing driver or turn one out. Remove the taper from one side of an old...