by Donnie Hurt | Apr 5, 2018 | CYLINDER HEADS

SEAT CUTTING TIPS When cutting in valve seats with a single, multi angle blade, especially new ones, try to do the least amount of work with the profile tool as possible. For instance, if the bottom angle is 75°, cut as much of the seat away as you can with that...

by Donnie Hurt | Apr 4, 2018 | ASSEMBLY

AFM DELETE THE RIGHT WAY When performing a performance camshaft upgrade on a LS engine that is originally equipped with the Active Fuel Management system (AKA: AFM or DOD) it is advised to remove the AFM solenoid assembly from the engine and convert the engine to a...

by Donnie Hurt | Mar 23, 2018 | CYLINDER HEADS

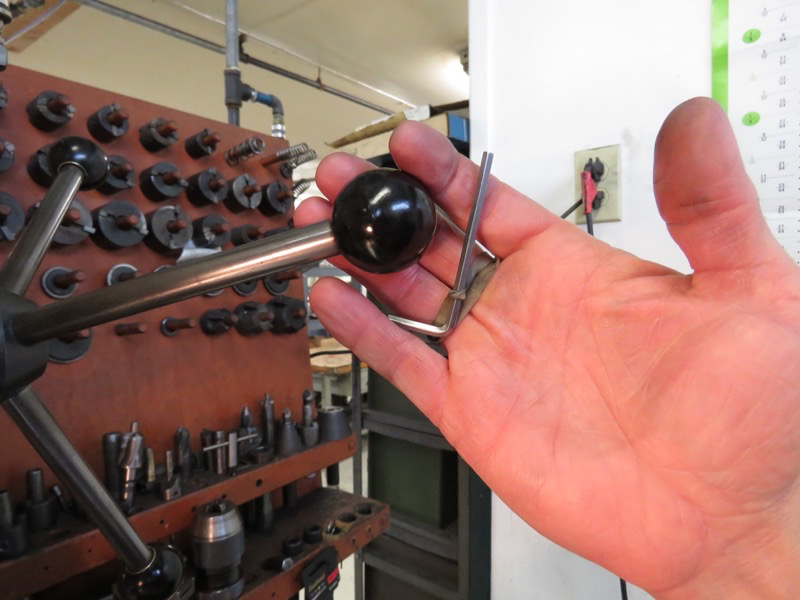

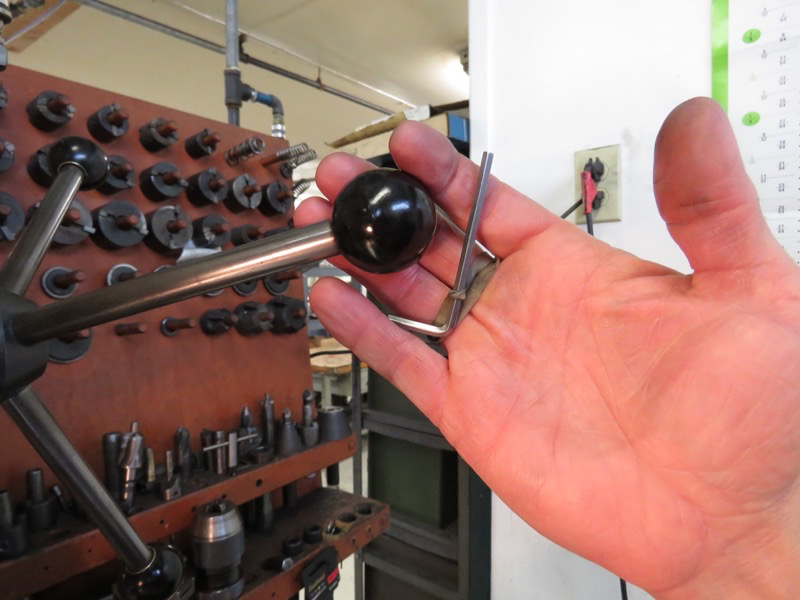

ELIMINATE WASTED MOTION I use an 1/8” allen wrench to insert and extract the pilot while doing valve jobs on cylinder heads. I would frequently misplace this little tool between seats, so I started using a rubber band to keep it attached to the palm of my hand. This...

by Donnie Hurt | Mar 17, 2018 | TOOLING

CHERRYHOPPER I took an old Grasshopper mower and made a power zero turn cherry picker out of it. The thing I really like about it is how maneuverable it is around the shop and outside. Another advantage is no legs sticking out front, I can drive right up to a machine...

by Donnie Hurt | Mar 15, 2018 | TOOLING

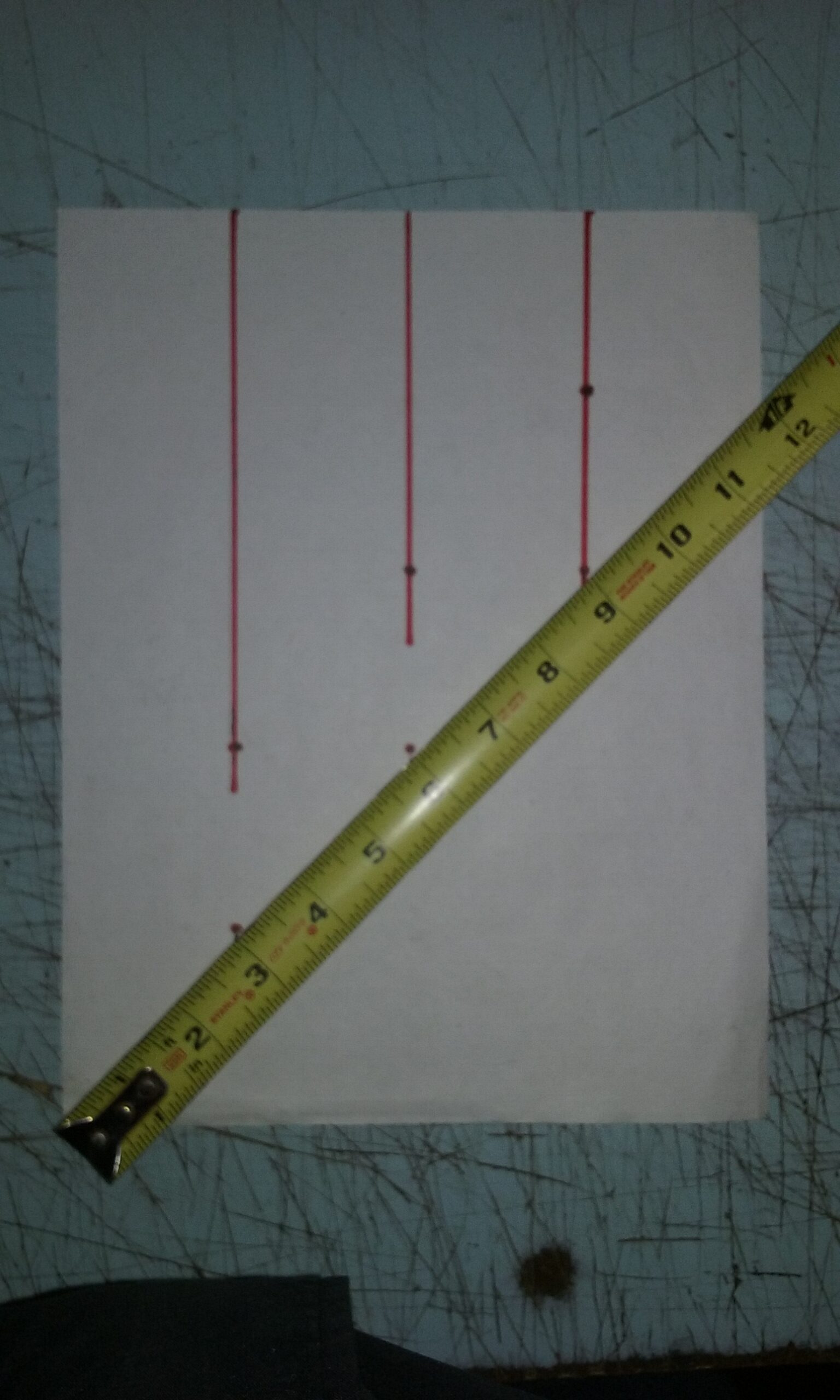

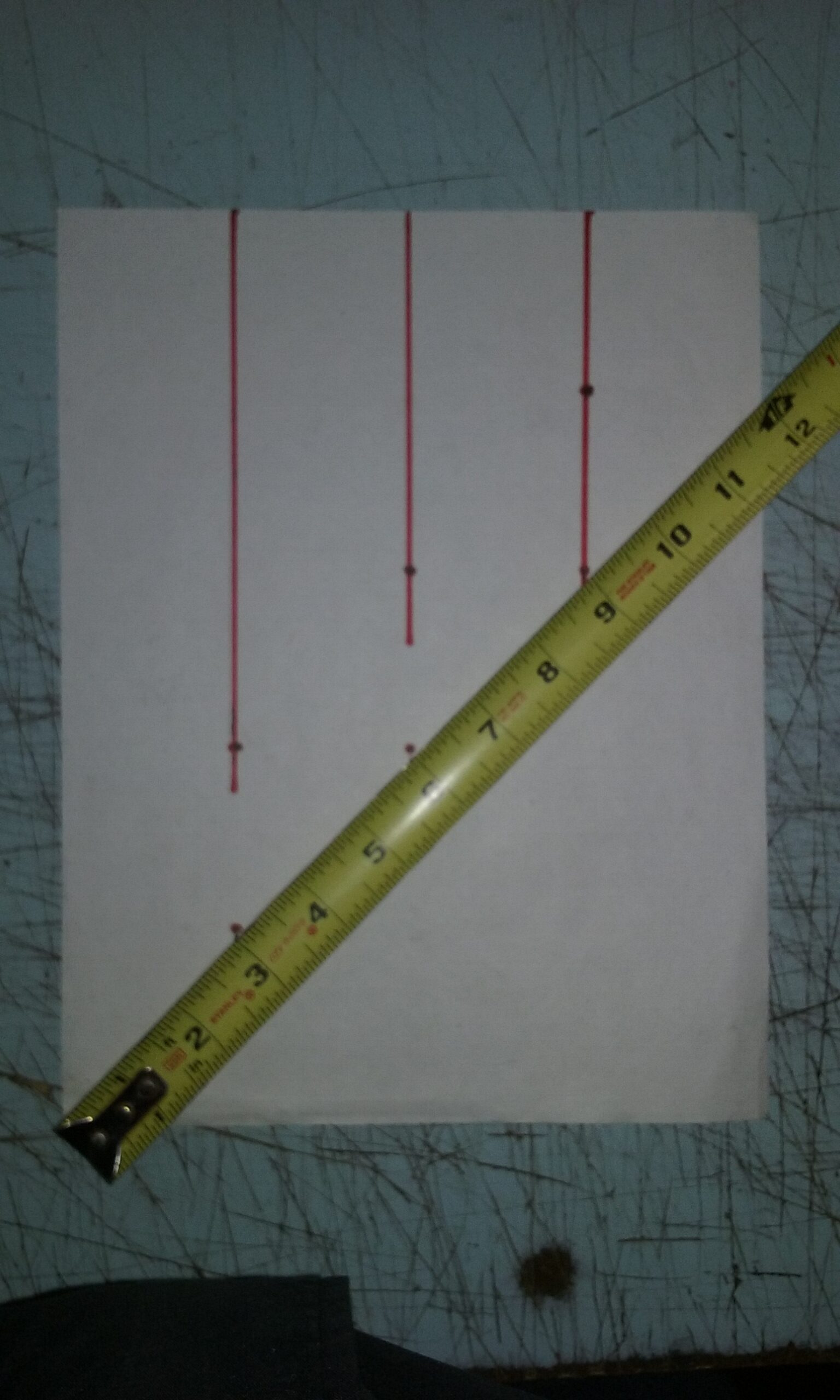

EASY WAY TO DIVIDE EVENLY If you need to divide an item into an even number of segments, there is no need to do mathematical calculations. Take your measuring device and angle it across your work so that it is set on a number divisible by the number of segments you...