by Donnie Hurt | Nov 1, 2017 | BLOCK WORK

OIL GALLEY FIX Priming the engine with a 1⁄2-drill and getting oil to all rockers without this mod takes 36 minutes. After the mod it takes less than a minute. Here’s what I do on Dart blocks. I’ve attached some pics as a visual guide. The lifter galley hole is 7/16...

by Donnie Hurt | Oct 1, 2017 | TOOLING

BOLTS AS HANDLES Sometimes, the simplest thing can become the perfect tool. To properly install a camshaft doesn’t need an expensive special tool. A long bolt or 2 can make a great camshaft installation tool. Stack a pile of fender washers on your bolt for a...

by Donnie Hurt | Oct 1, 2017 | GASKETS & SEALING

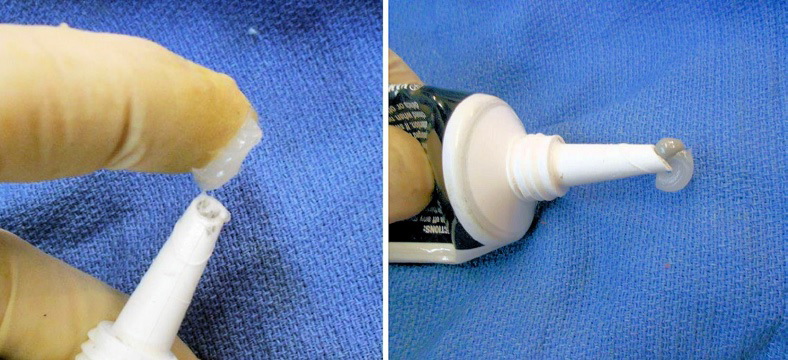

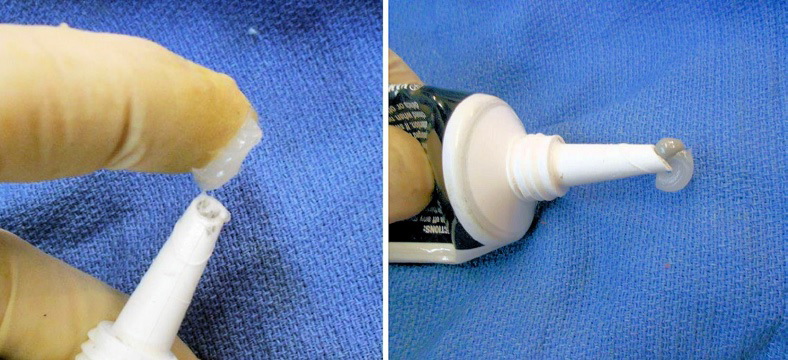

CAP-ILLARY SEAL The screw on caps for many sealants do nothing to prevent the sealant from drying in the nozzle. I used to hate digging out the dried Sealant. Not anymore. My co-worker told me to pack a 1/4 of the nozzle with lube. If no air gets to the sealant, it...

by Donnie Hurt | Oct 1, 2017 | BLOCK WORK

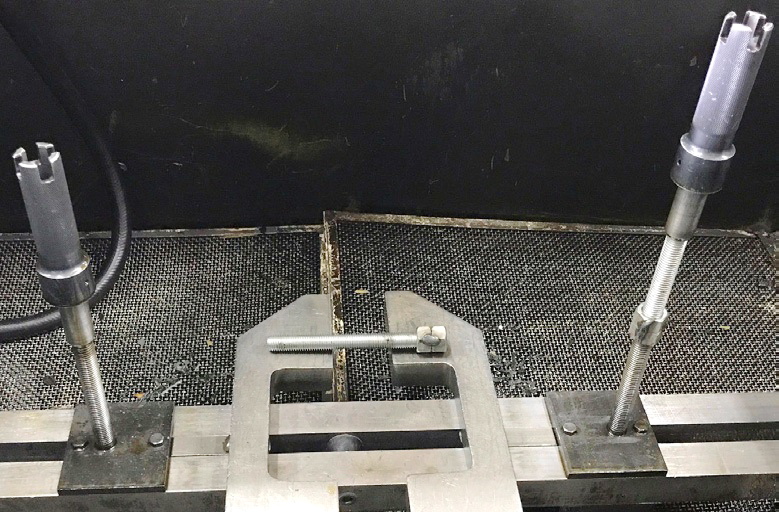

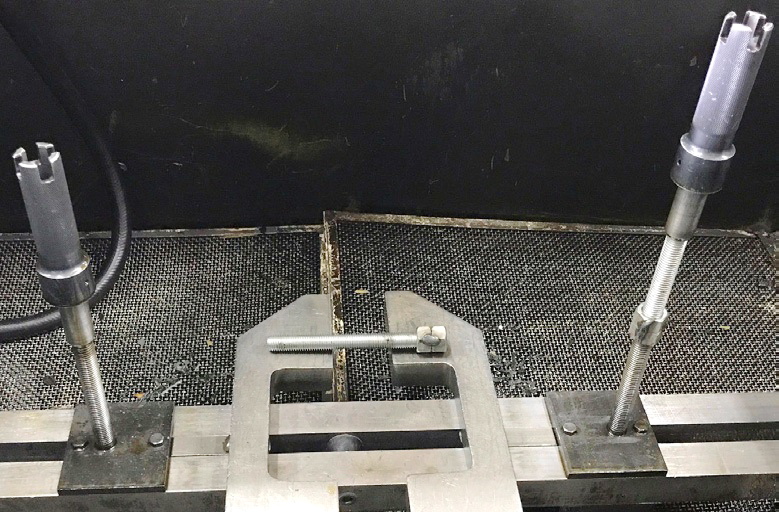

SUNNEN POWER HONE EXTENSIONS Because Sunnen’s hold downs are limited in their length, we made extensions to hold down various components. I use 3⁄4 -10 all-thread for the extensions and I can mount various work pieces with existing Sunnen threaded hole downs. This has...

by Donnie Hurt | Oct 1, 2017 | CYLINDER HEADS

SURFACE PLATE ADAPTER Some cylinder heads, like small block Mopars, have the intake manifold bolt holes at a slight angle from the manifold flange. This makes it hard to mount on our surfacing machine milling plate because, when you tighten up the mounting studs...