by Donnie Hurt | Apr 1, 2017 | BLOCK WORK

THE OLD OIL PUMP TRICK When align honing Small or Big Block Chevrolets I always install an old oil pump on the #5 main cap. The added stress can change the main bore up to .001” to allow for distortion of the bore when the engine is fully assembled. Joe Foellmer...

by Donnie Hurt | Apr 1, 2017 | TOOLING

OLD PARTS AS STANDARDS Here is a quick way to double check you settings on your Dial Bore Gauge or Sunnen AG-300 Rod Gauge. If you have an engine you work on all the time, make a simple standard from old parts to make sure you are set up correctly. I took a couple...

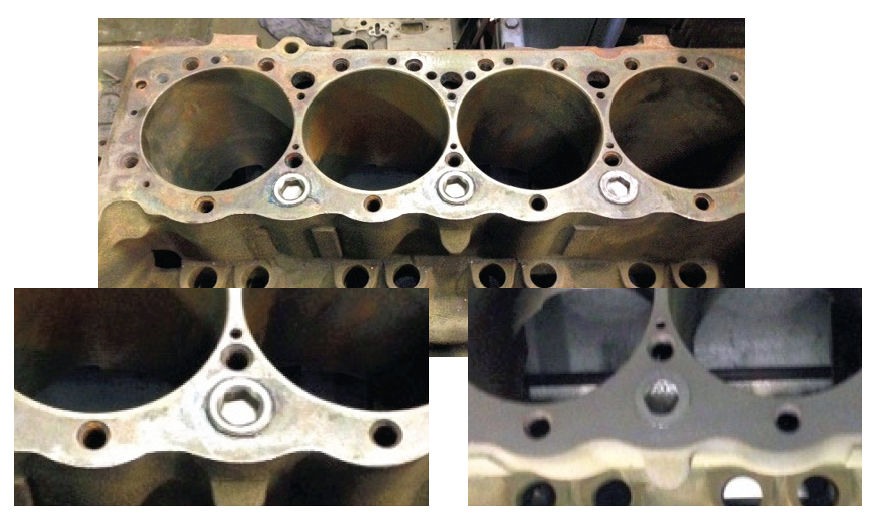

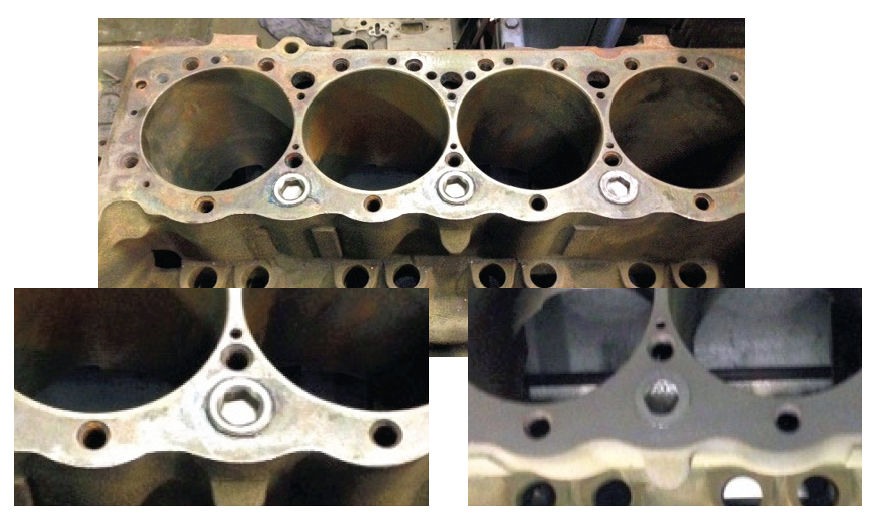

by Donnie Hurt | Mar 3, 2017 | BLOCK WORK

BLOCK CRACK FIX On 400 SB Chevy blocks, the deck is the weak link. They have a tendency to crack between the water holes. I have found a successful fix for this. I drill and tap the water holes for tapered pipe plugs. Once they are sealed and threaded into the block,...

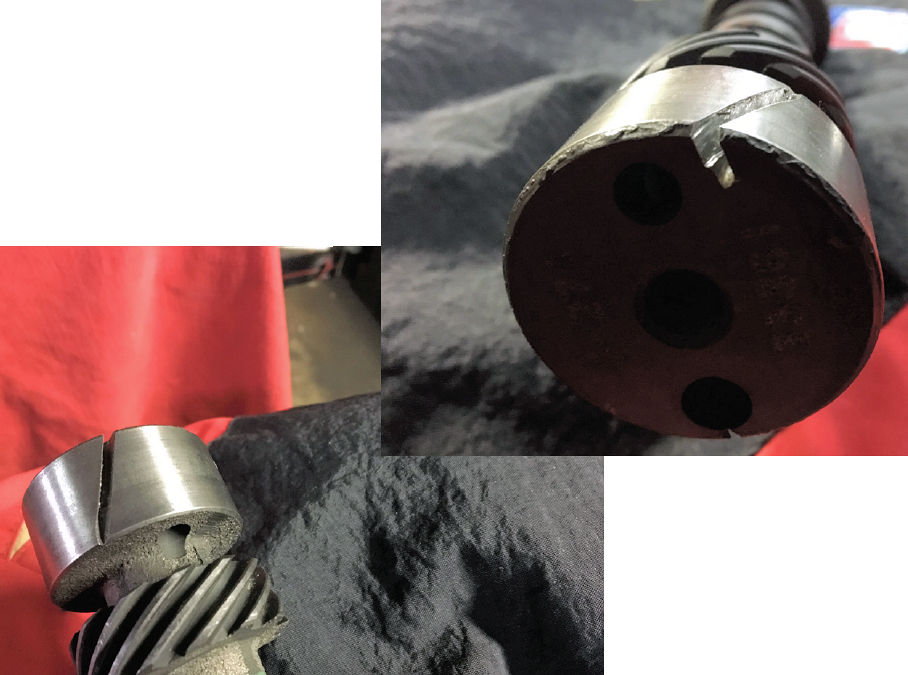

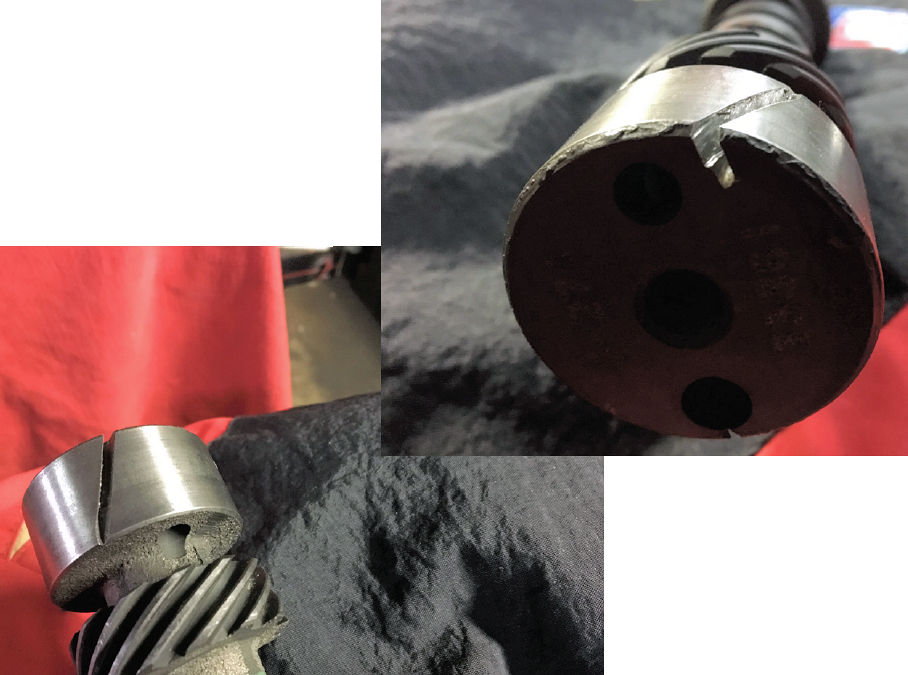

by Donnie Hurt | Mar 3, 2017 | CRANKSHAFTS & CONNECTING RODS

RELUCTOR WHEEL INSTALLATION Many late model engines, like the LS series GM V8’s, use a press fit reluctor wheel as a crankshaft trigger. When the need arises to swap the crankshaft reluctor, some companies sell a tool for approximately $200. Taking one off is as...

by Donnie Hurt | Mar 3, 2017 | BLOCK WORK

CAM BEARING BORING TOOL Camshafts will often times not fit into newly installed cam bearings. Since most factory cam bearings are bored in place, cam bore alignment is not an issue from the factory, but becomes an issue with finish machined bearings. I use an old...