by Donnie Hurt | Oct 1, 2015 | CYLINDER HEADS

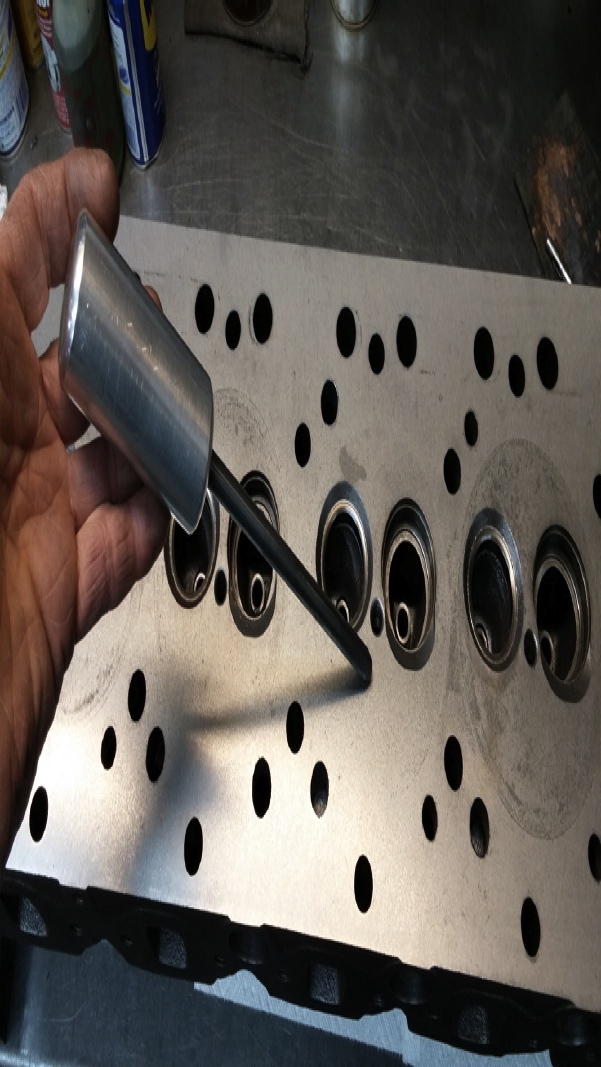

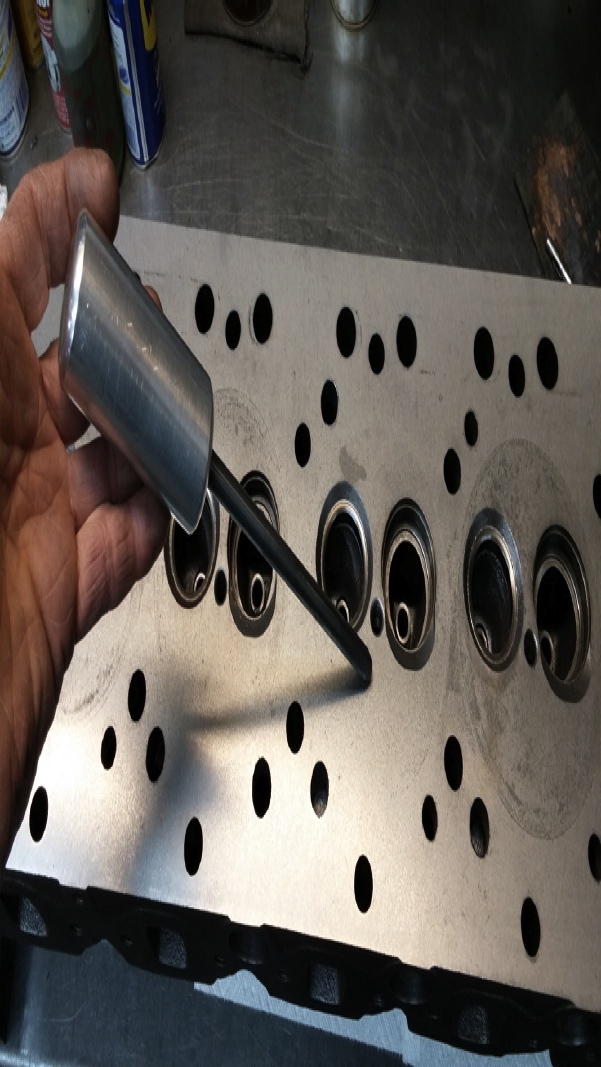

RESIZING VALVE SEALS Every once in a while we get metal clad stem seals that just don’t fit snugly enough on the guide to suit us. Because of the volume of metal clad seals we use and my unwillingness to throw them away or send them back, we have a drawer full of new...

by Donnie Hurt | Oct 1, 2015 | DISASSEMBLY & CLEANING

PLUG EXTRACTION 101 Many Toyotas and Hondas have spark plug tubes on their cylinder heads. When these heads get over heated, it can melt the spark plug boot in the tube. Some of these tubes do not come off. There is a way to get the boot out quickly and easily. With...

by Donnie Hurt | Oct 1, 2015 | OPERATIONS

MEASURING TOOL MAINTENANCE I was once in a shop where the Sunnen dial bore gauge setting standards were so worn on their Sunnen CF1126 that it messed up every job in the boring department and no one noticed. The ends of the changeable standards had divots worn in them...

by Donnie Hurt | Oct 1, 2015 | CYLINDER HEADS

GOT A HANDLE I like to use my Serdi pilots as go-no-go gauges when I hone valve guides. I made this aluminum handle from a piece of 1-1/2” diameter rod. I turned the outside for a comfortable grip and bored the center to hold my pilots. I select the appropriate one...

by Donnie Hurt | Oct 1, 2015 | TOOLING

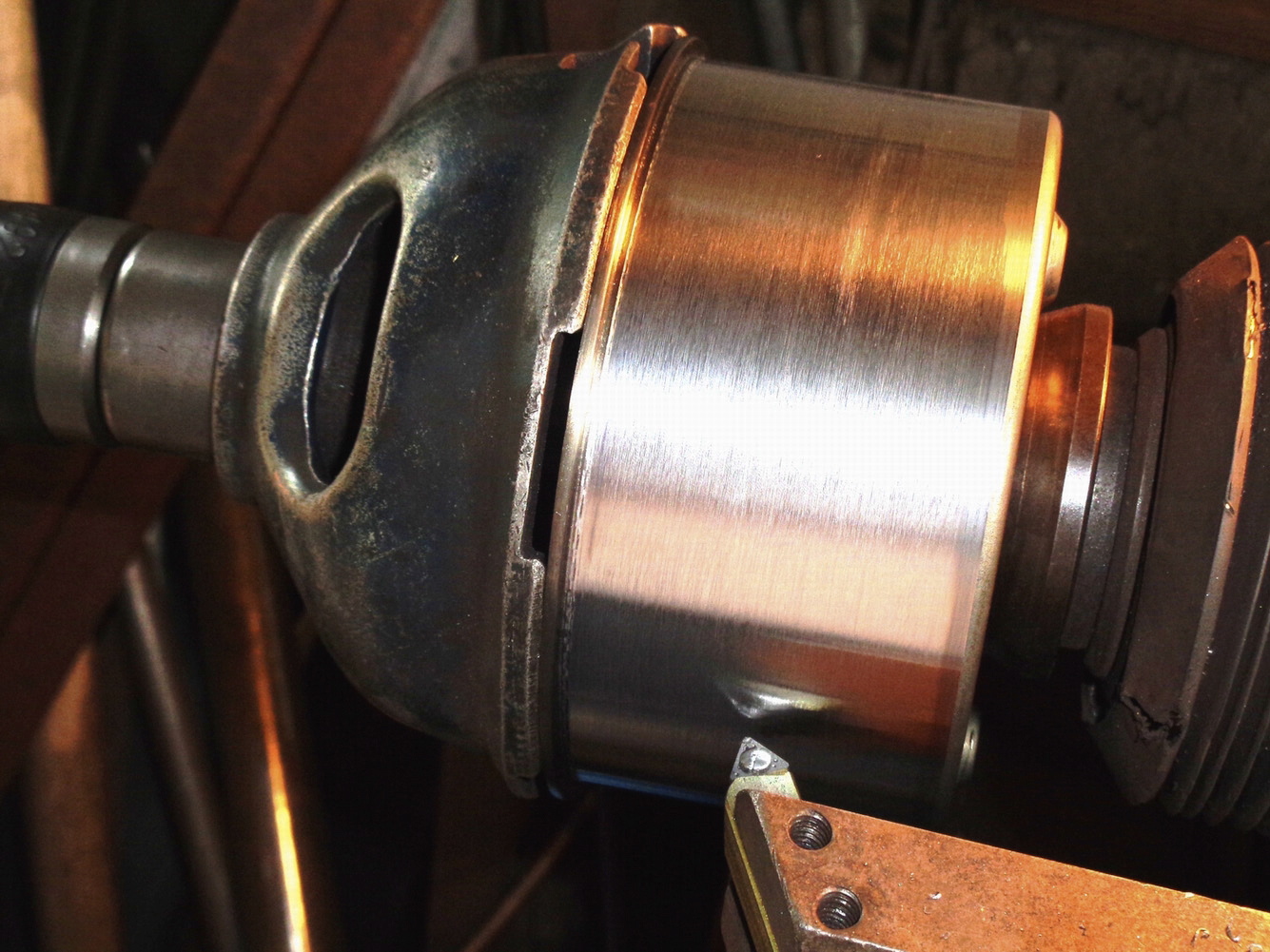

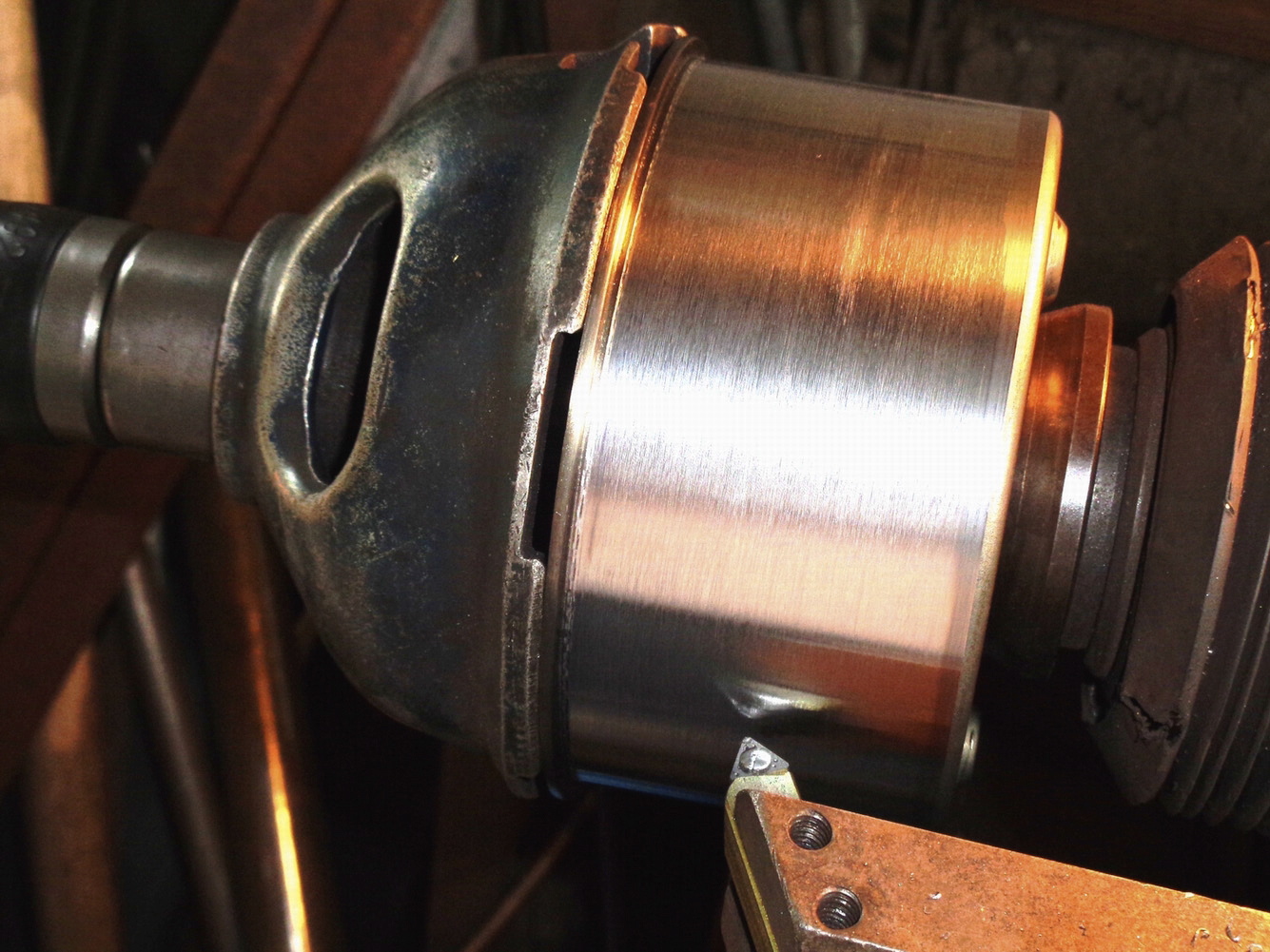

FOR MORE THAN JUST ROTORS AND DRUMS Our brake lathe does not see as many rotors and drums as it once did but we are finding new uses for this great machine. With its large assortment of adapters and cones, it becomes a natural for mounting hard to hold parts for...