by Donnie Hurt | Sep 1, 2023 | LUBRICATION & COOLING

OIL PUMP PRESSURE TESTER When modifying oil pumps for max relief pressure, it can be a crapshoot until the engine is running. This is one of my 50-year-old test units manufactured essentially from spare parts. A main cap, pressure gauge, and a sealable container. (To...

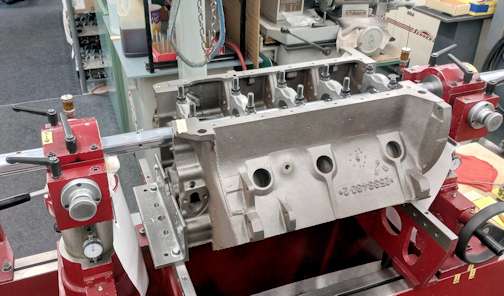

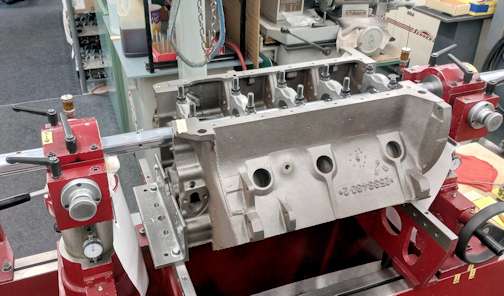

by Donnie Hurt | Aug 1, 2023 | BLOCK WORK

GET IT RIGHT When line boring and trying to figure out bearing clearance on an engine family that’s out of your norm, check your clearances before you start. Torque a bearing into a good bore and use the stock fasteners if you plan on aftermarket bolts or studs,...

by Donnie Hurt | Aug 1, 2023 | TOOLING

HEIGHT GAUGE Checking and calibrating your installed height gauges is something that should be done occasionally. If the height is off, simply reference mark where the scale ring needs to be, heat, remove and reinstall in the correct position. Ron Flood Cedar Machine...

by Donnie Hurt | Aug 1, 2023 | OTHER SHOP WORK

REMOVING BOLTS BY CANDLE Removing broken bolts and studs can be surprisingly easy. First clean the area, then you heat up the broken bolt or stud. Let it cool for 5 minutes. Put a candle or paraffin wax on the broken bolt or stud. Let it sit for another 15 minutes...

by Donnie Hurt | Aug 1, 2023 | DISASSEMBLY & CLEANING

RING ORGANIZER I made these piston ring organizer tabs for keeping rings in their perspective cylinders while final washing them in the sonic cleaner tank. Works great and saves time vs hand washing them in solvent. We also found some reusable zip ties, as I...