by Donnie Hurt | May 1, 2023 | CYLINDER HEADS

GUIDE SAVER To avoid cracking the guide when ball broaching liners I made collars that slip fit over the guide. I’ve used large valve guides, aluminum, and steel round stock to make them. The time invested is quickly offset by not needing to replace cracked...

by Donnie Hurt | May 1, 2023 | PISTONS & RINGS

GRINDING THE RAILS When grinding the thin steel oil rails on a ring grinder, lay it on a used cast iron second ring and grind them both together. This reduces the chance of the rail biting or fluttering and damaging it. If you’re careful, you can grind the two for...

by Donnie Hurt | May 1, 2023 | BLOCK WORK

ADDED HONE TANK FILTRATION Lay used air filter rolls under your engine block, or other parts being honed, to collect as much grit as possible. It saves you time and money by extending the life of the oil filter on your machine. We triple up the layers directly under...

by Donnie Hurt | Apr 1, 2023 | CYLINDER HEADS

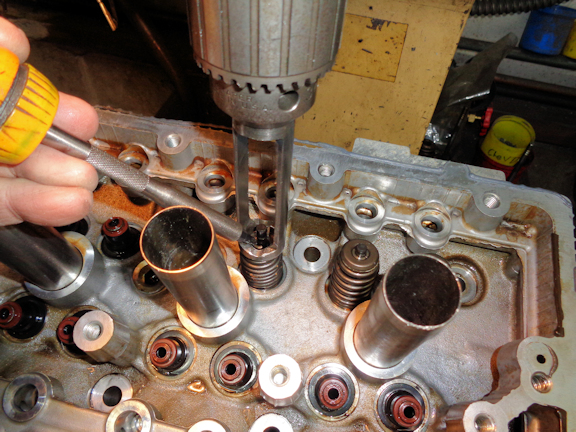

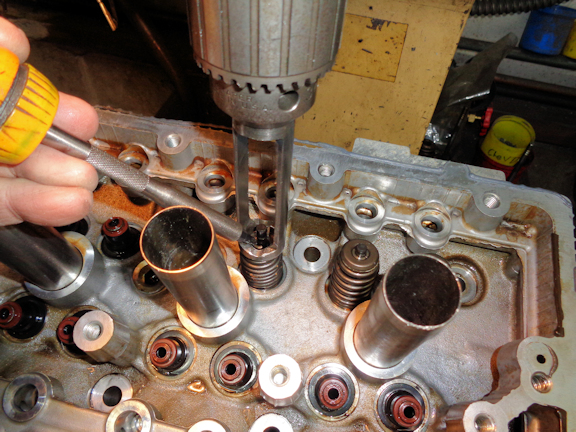

VALVE KEEPERS CAN GO FLYING I use my magnetic screwdriver with a small diameter Phillips bit to collect the valve keepers as I compress the springs on overhead cam cylinder heads. The small Phillips bit becomes magnetized when it is inserted into the magnetic...

by Donnie Hurt | Apr 1, 2023 | DISASSEMBLY & CLEANING

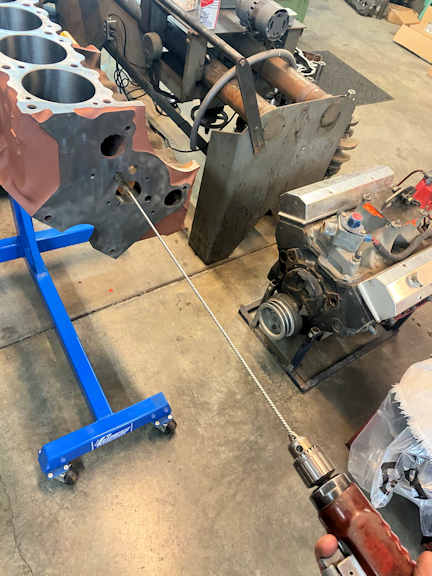

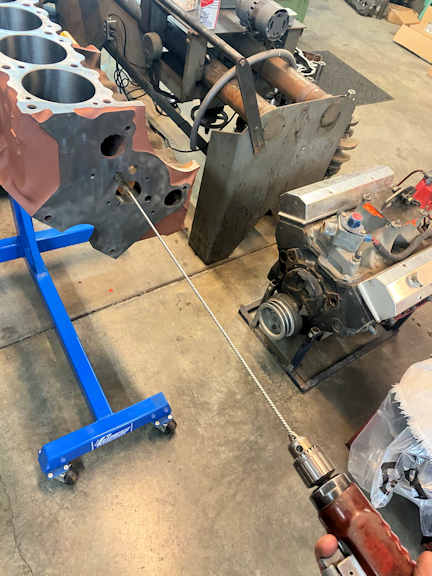

OIL PASSAGE CLEANING When the passages are needing a little extra cleaning, I cut the eyelet off the end of the metal oil galley brushes so I can chuck them into a drill. I have found this method to work much better than by hand. Bruce Serene Hillsboro Racing Engines...