by Donnie Hurt | Oct 1, 2022 | TOOLING

CATTLE CONTROLLER For anyone that has ever stepped away while they were filling their coolant tank, I have the perfect solution to keep from spending a portion of your day from cleaning up the mess. The simple installation of a cattle waterer, which keeps the level...

by Donnie Hurt | Oct 1, 2022 | LUBRICATION & COOLING

BEAT THE HEAT Too much heat can destroy an engine. Gas engines are designed to operate between 190-220 degrees F, hotter than 220 and you’ve got an overheat situation. As an engine overheats, aluminum material will begin to warp, expand and even crack. A warped...

by Donnie Hurt | Oct 1, 2022 | CYLINDER HEADS

SPECIAL AND NUMBERED STONES If I need to touchup a seat after machining, even on the Serdi, I go to my numbered stones and holders. I have three numbered holders and always use them as pairs. Sometimes if I just need a quick touch up and the stone is good, I...

by Donnie Hurt | Sep 1, 2022 | CRANKSHAFTS & CONNECTING RODS

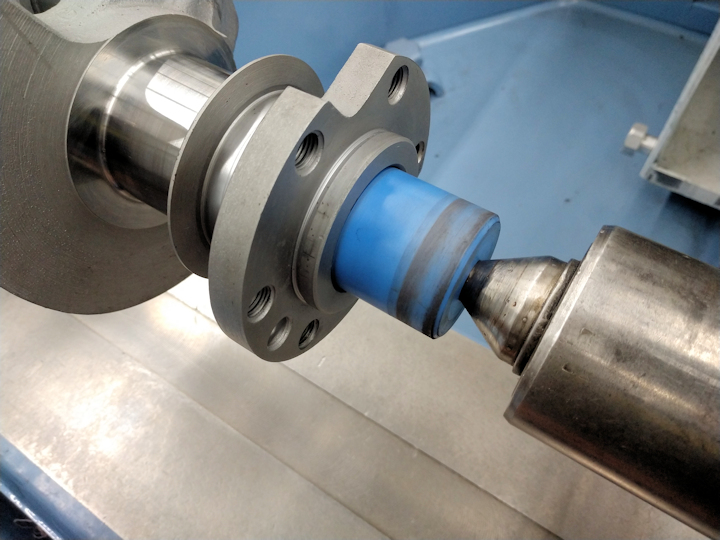

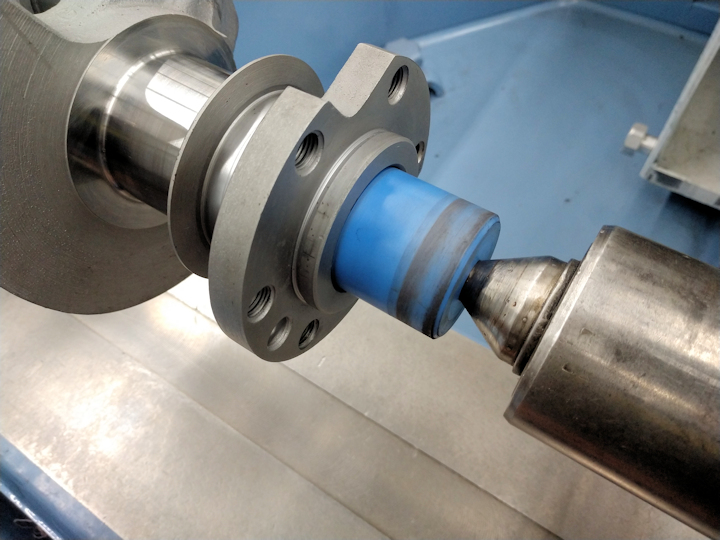

QUICK CRANK CENTERS To make it quick and easy to mount cranks in the grinder and especially the lathe for polishing, I made inserts for various engine families. Delron or that type of material works great and I give them about .001” clearance so they are reasonably...

by Donnie Hurt | Sep 1, 2022 | TOOLING

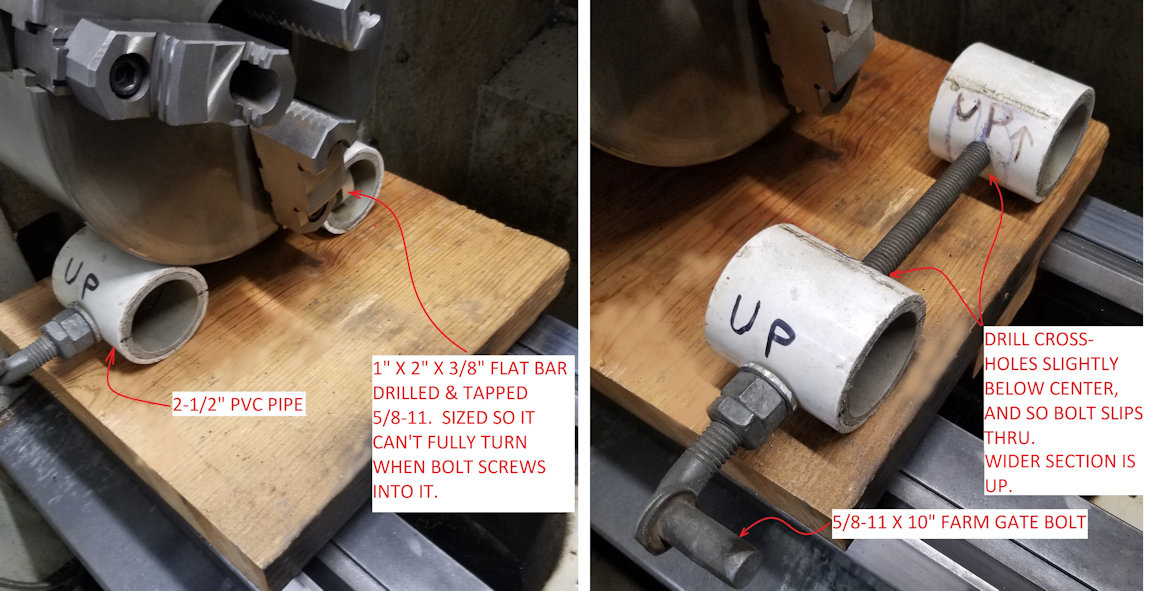

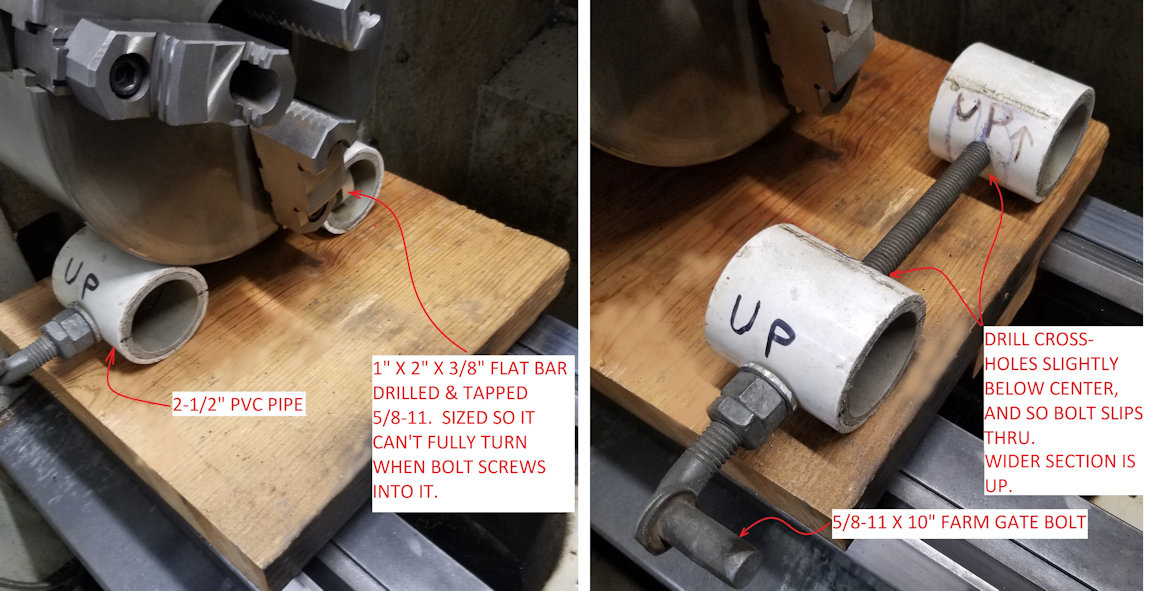

CHUCK SUPPORT I made this simple chuck support to help make changing chucks on my lathe & crank grinder much easier. Made from PVC pipe, a farm gate post bolt (or all-thread rod), and hardware, this adjustable chuck support lets the chuck slide off and on the...