by Donnie Hurt | Apr 1, 2022 | OTHER SHOP WORK

REMOVING PIPS Often when parting off a work piece in the lathe, the tool may leave a “pip” or thin ring attached to the work piece….even when using a right-hand cut-out insert or blade tip. Here’s an easy, quick way to remove the unwanted...

by Donnie Hurt | Apr 1, 2022 | CRANKSHAFTS & CONNECTING RODS

HOW FITTING On some crankshafts, the pilot bushing bore is undersize or irregular. Driving in a bushing with too much interference would lead to the I.D. of the pilot bushing being too small for the transmission input shaft. Simply mic the bore and adjust the bearing...

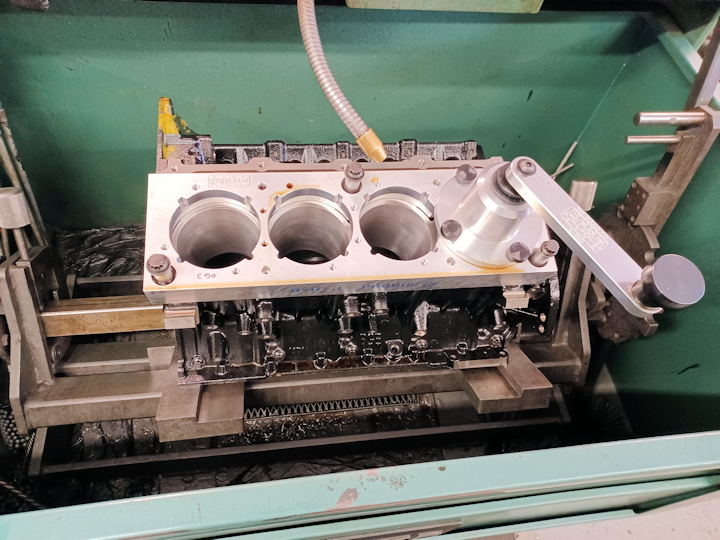

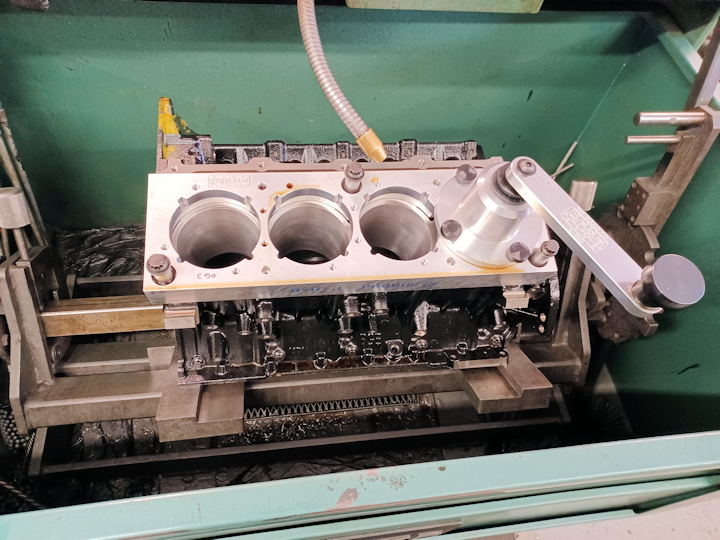

by Donnie Hurt | Apr 1, 2022 | BLOCK WORK

CLEAN CUT When cutting O-ring and receiver grooves for top fuel hoops, it’s important to have plenty of cutting oil to get a nice clean cut in the heads and block. Instead of spraying penetrating oil all over the bench, we do them in the honing tank and flood the work...

by Donnie Hurt | Apr 1, 2022 | OTHER SHOP WORK

BALANCING TIMESAVER In the past, I balanced individual parts like everyone else; match all to the lightest, piston to piston, rod to rod, etc. But a few years ago, I started following this procedure: Assign all parts an identifying letter, then weigh and record all...

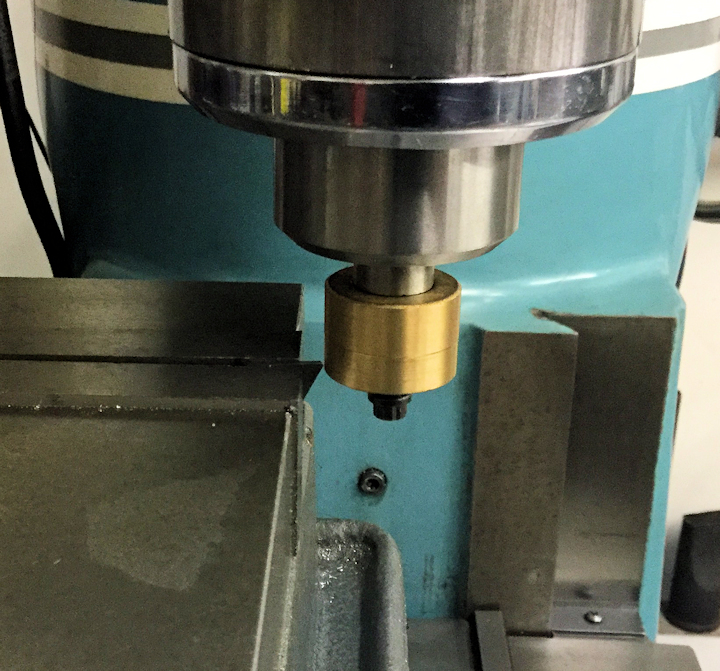

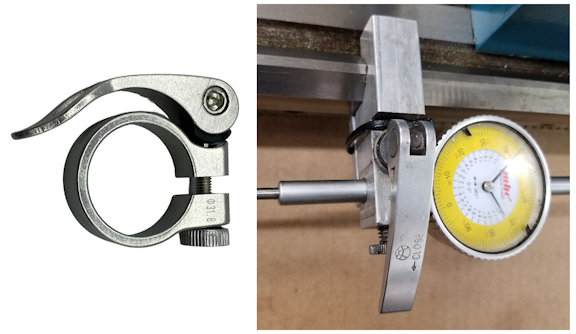

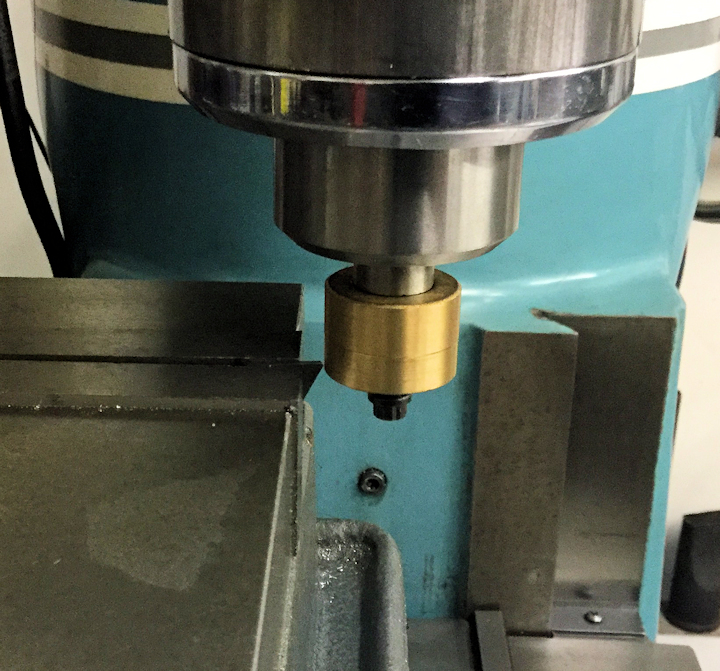

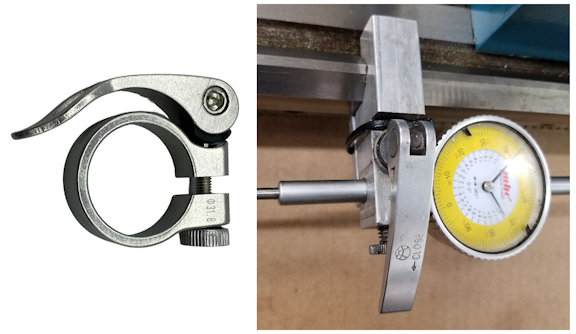

by Donnie Hurt | Mar 1, 2022 | TOOLING

TRAVEL DIAL For lathes without a DRO, a 2″ travel dial indicator to measure carriage travel is handy. I quickly made this simple compact indicator mount clamp from two pieces of scrap aluminum. To eliminate the need for a wrench to tighten or loosen it when...