by Donnie Hurt | Feb 1, 2022 | CRANKSHAFTS & CONNECTING RODS

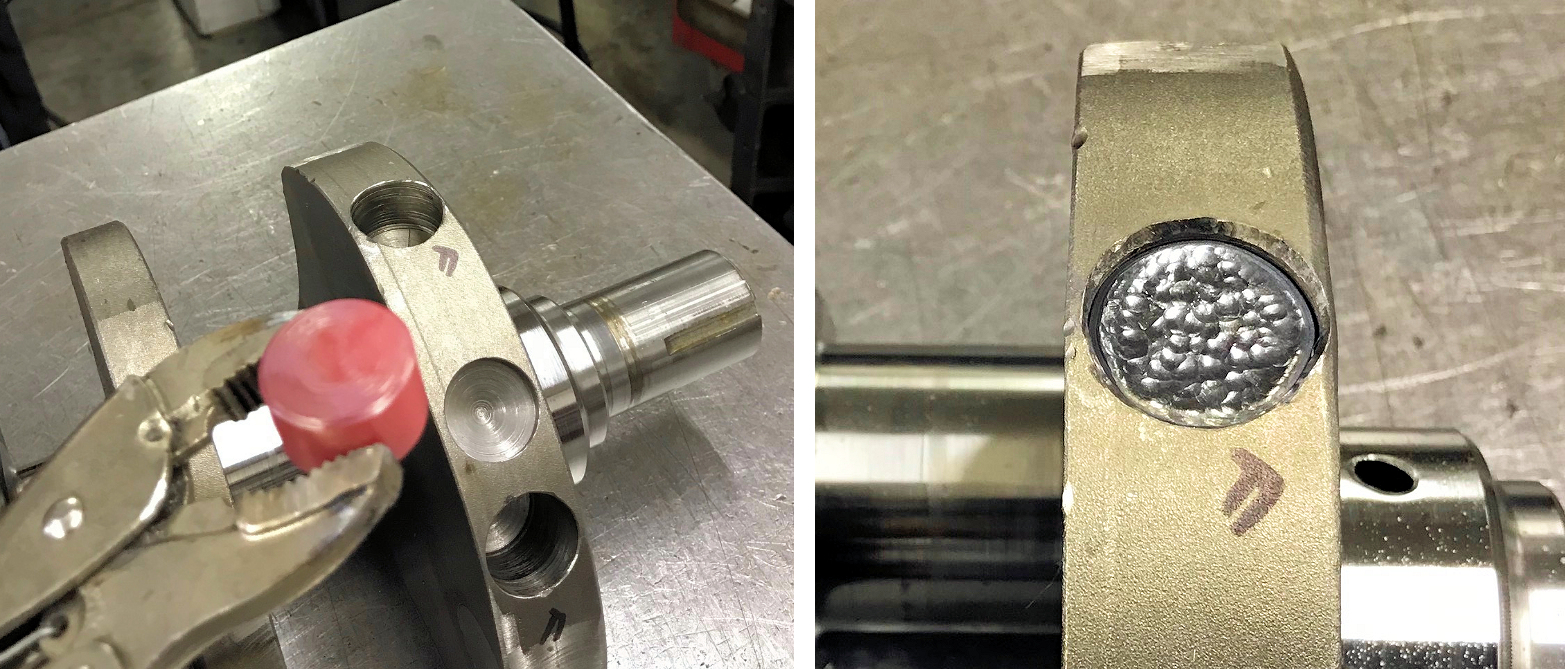

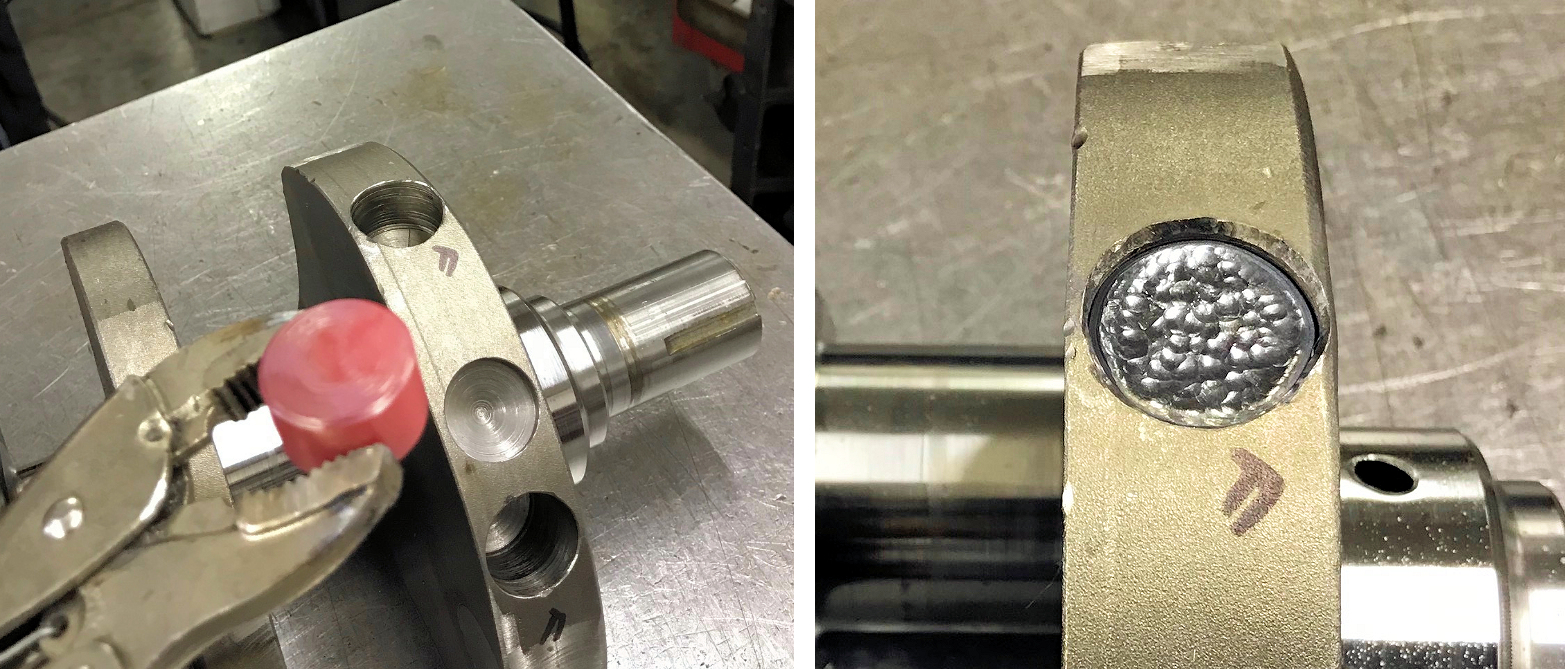

REFILLS When balancing a crankshaft for heavier parts, often you must add metal in an existing hole. If the hole was drilled with a regular drill bit, versus a spade drill, the hole can be irregular and oversized. It can be time consuming to try to make a slug that...

by Donnie Hurt | Jan 1, 2022 | CRANKSHAFTS & CONNECTING RODS

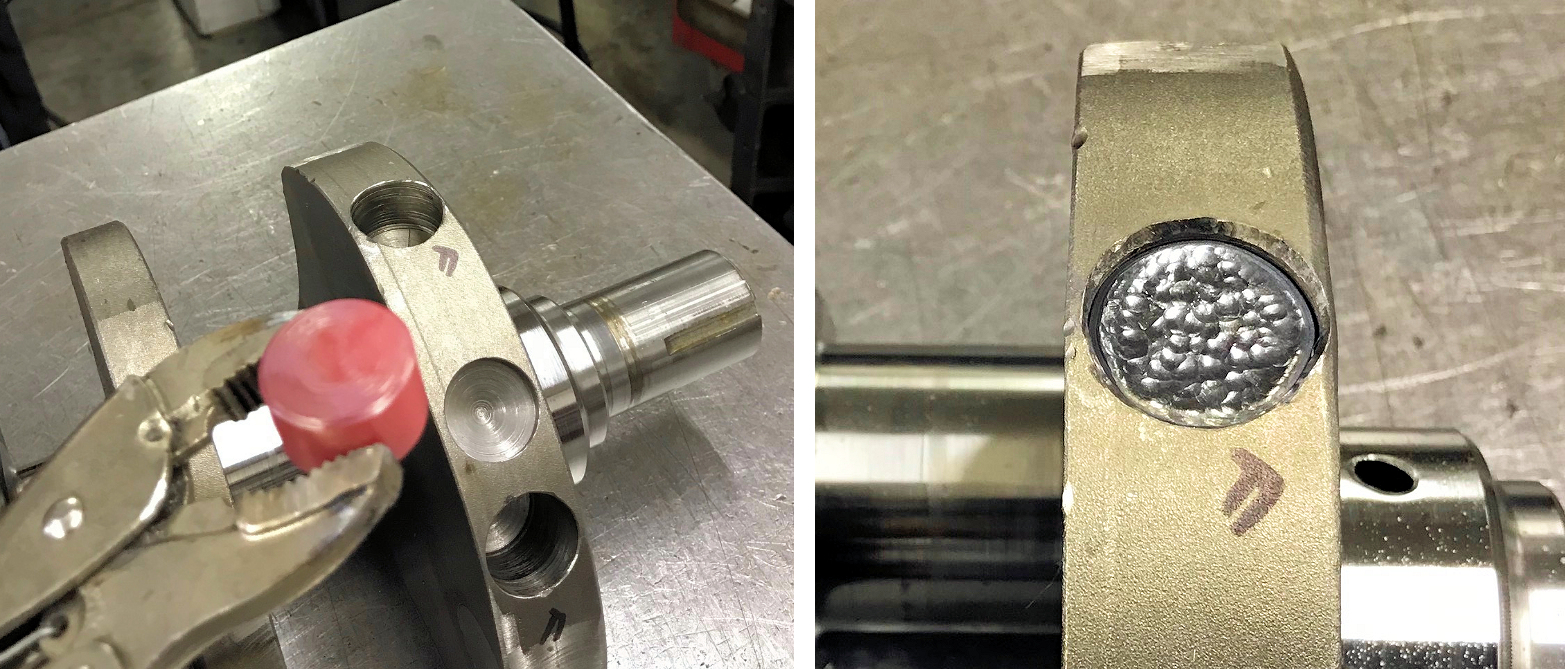

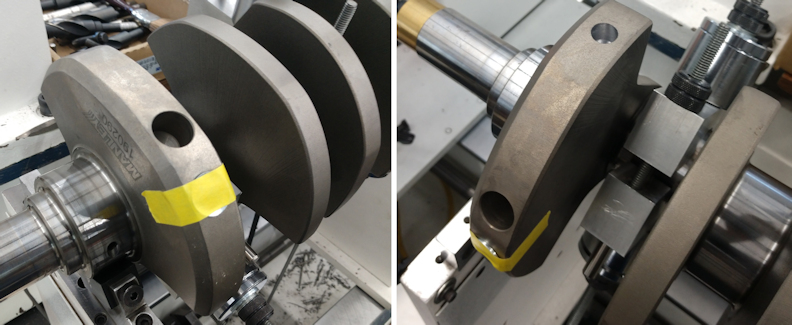

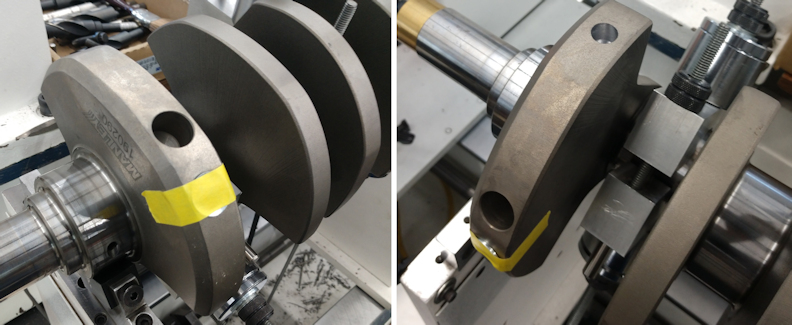

MOVE YOUR SPOT Sometimes when I first spin up a crank, the correction area is off the counterweight. Instead of grinding up by the rod throw, try adding weight to the opposite end if there are balance holes already. I taped in some flat disc plugs until the “spot”...

by Donnie Hurt | Jan 1, 2022 | TOOLING

BLOW THROUGH VACUUM If you end up chasing threads or tapping on a machine and don’t want to make a mess blowing them out, here’s a quick tip. Drill a hole in your vacuum cleaner nozzle and feed your blow gun nozzle through it. Now suck the chips up as you blow the...

by Donnie Hurt | Jan 1, 2022 | CRANKSHAFTS & CONNECTING RODS

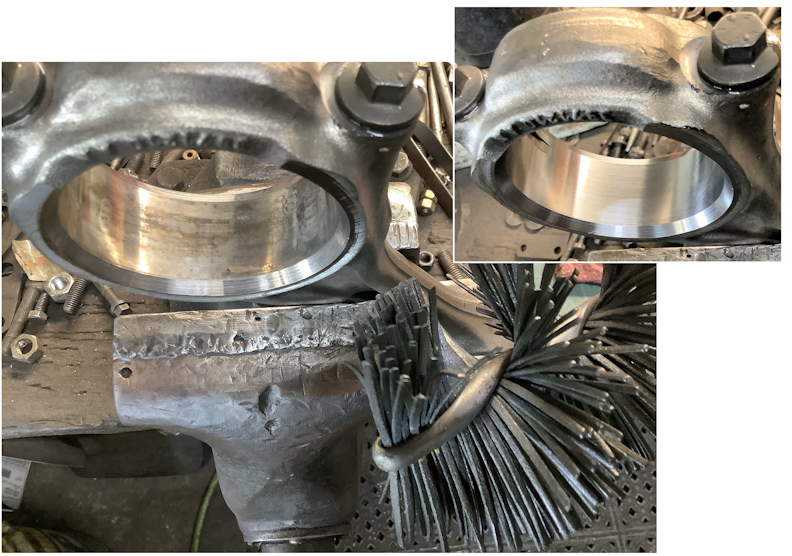

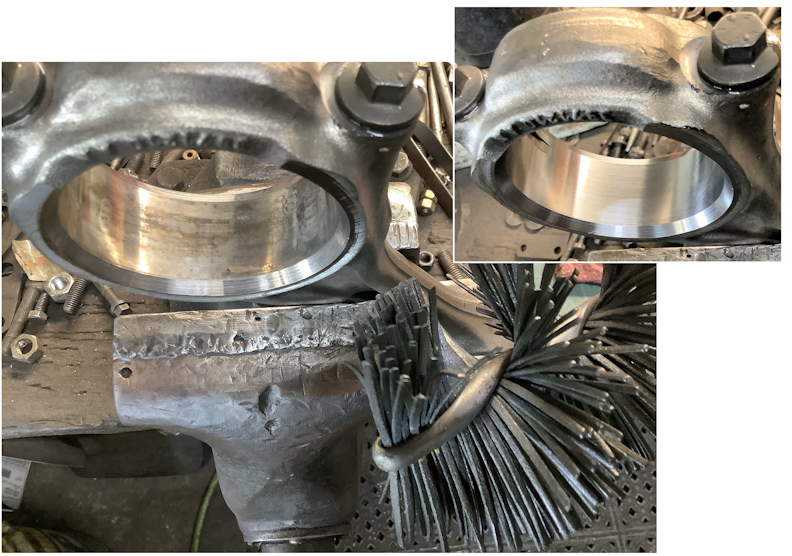

POLISHING THE BIG END Starting to see more and more cracked (powdered metal) connecting rods these days. After checking to make sure the size is correct, I use a plateau brush with a few drops of oil to clean up any rust or dirt. If you have a finished set of rods...

by Donnie Hurt | Jan 1, 2022 | DISASSEMBLY & CLEANING

EXTRACTING SHARP EDGES I like to chamfer the sharp edges on lifter bores after shotblasting blocks. I use a spiral flute extractor and just rotate it clockwise a few times with my fingers to remove any peened over edges. I find that it works better than a lot of my...