by Donnie Hurt | Sep 1, 2021 | OTHER SHOP WORK

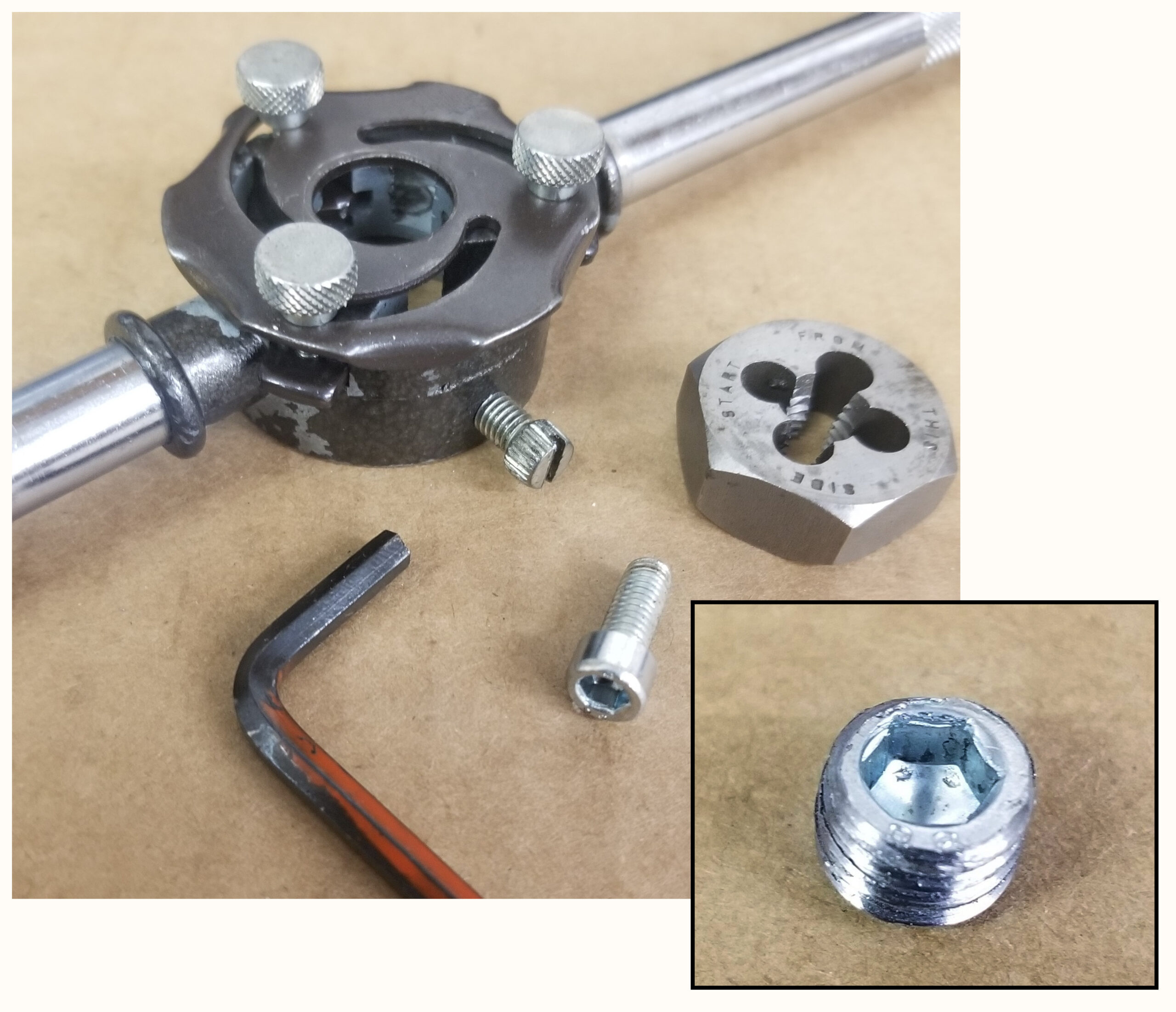

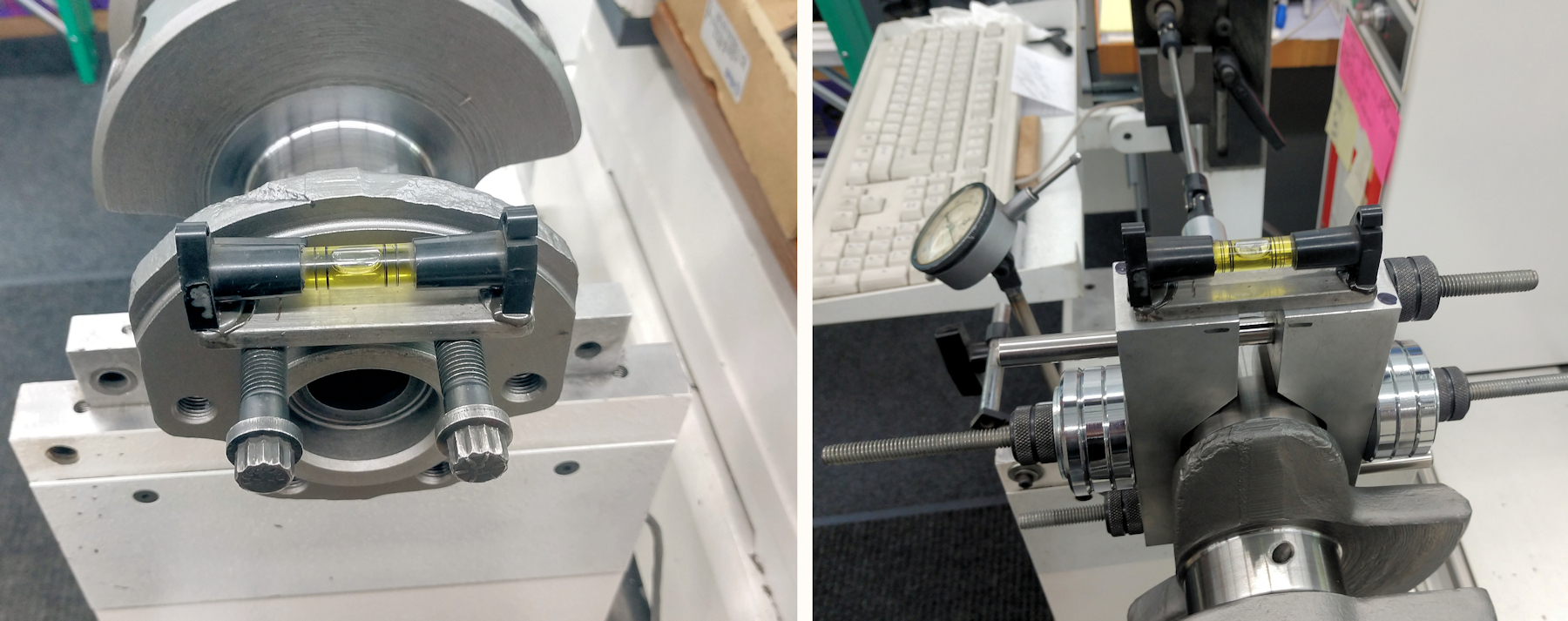

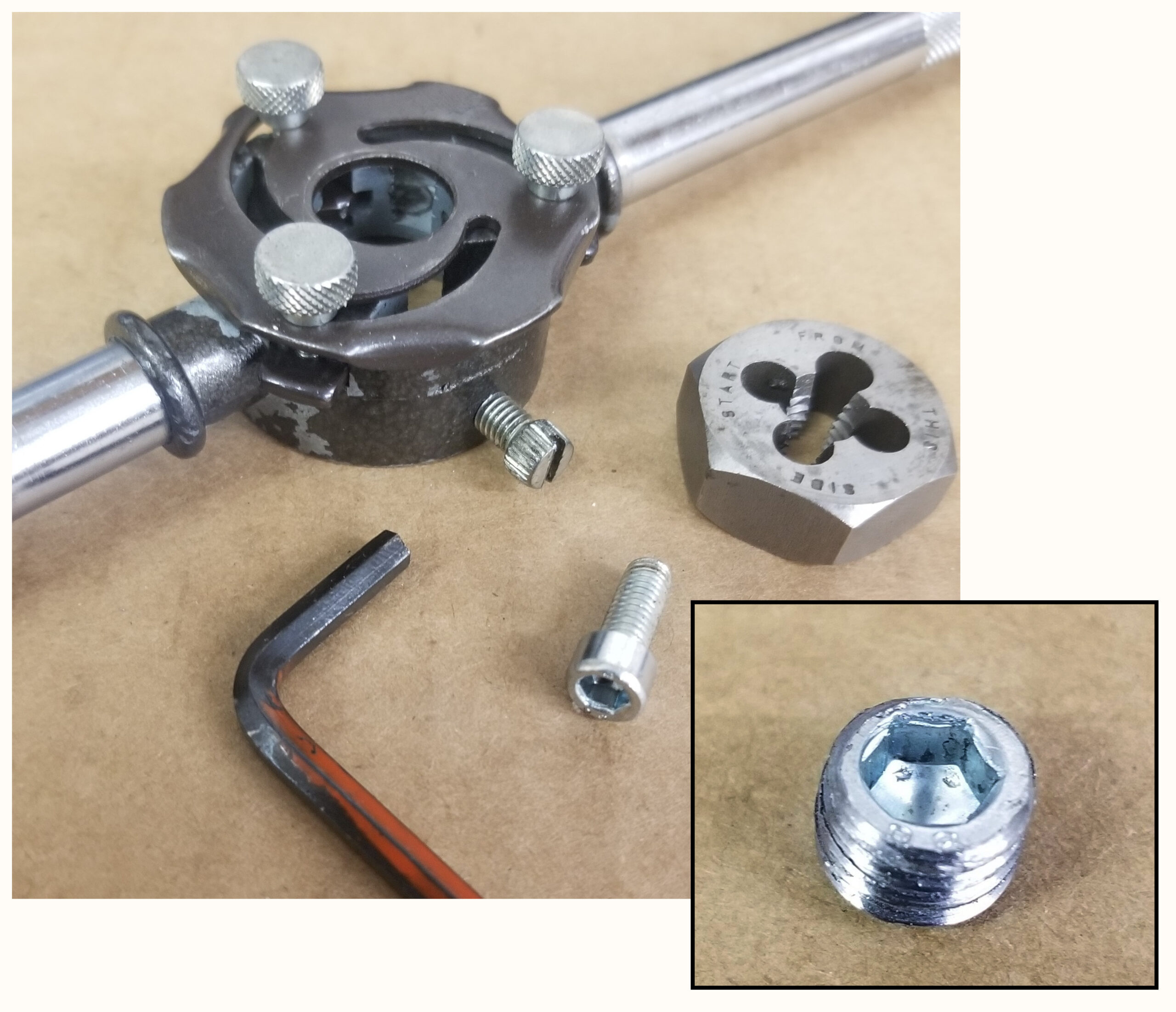

EMERGENCY FITTINGS In the event you come up missing a set screw or oil galley plug, and need to finish a job, one can be quickly made by threading the head of a stainless-steel hex-socket head cap screw. Then cut off and file the smaller original threaded portion of...

by Donnie Hurt | Sep 1, 2021 | CRANKSHAFTS & CONNECTING RODS

USED CRANK SPROCKET When balancing an externally balanced crankshaft, the harmonic damper needs to be installed at the correct location against the timing gear to maintain proper balance. Sometimes you might get a balance job and the timing gear is not on the crank....

by Donnie Hurt | Aug 1, 2021 | CRANKSHAFTS & CONNECTING RODS

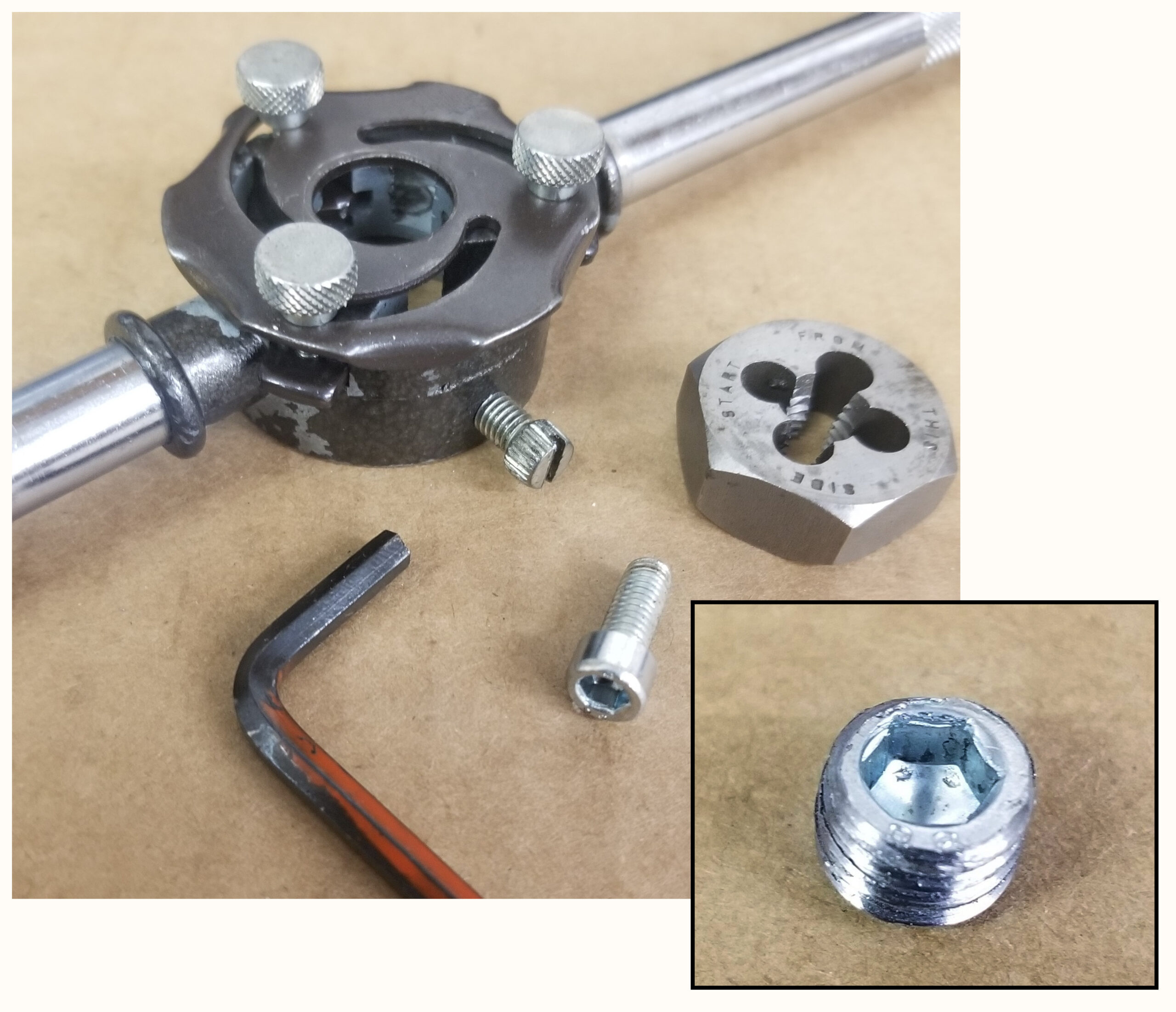

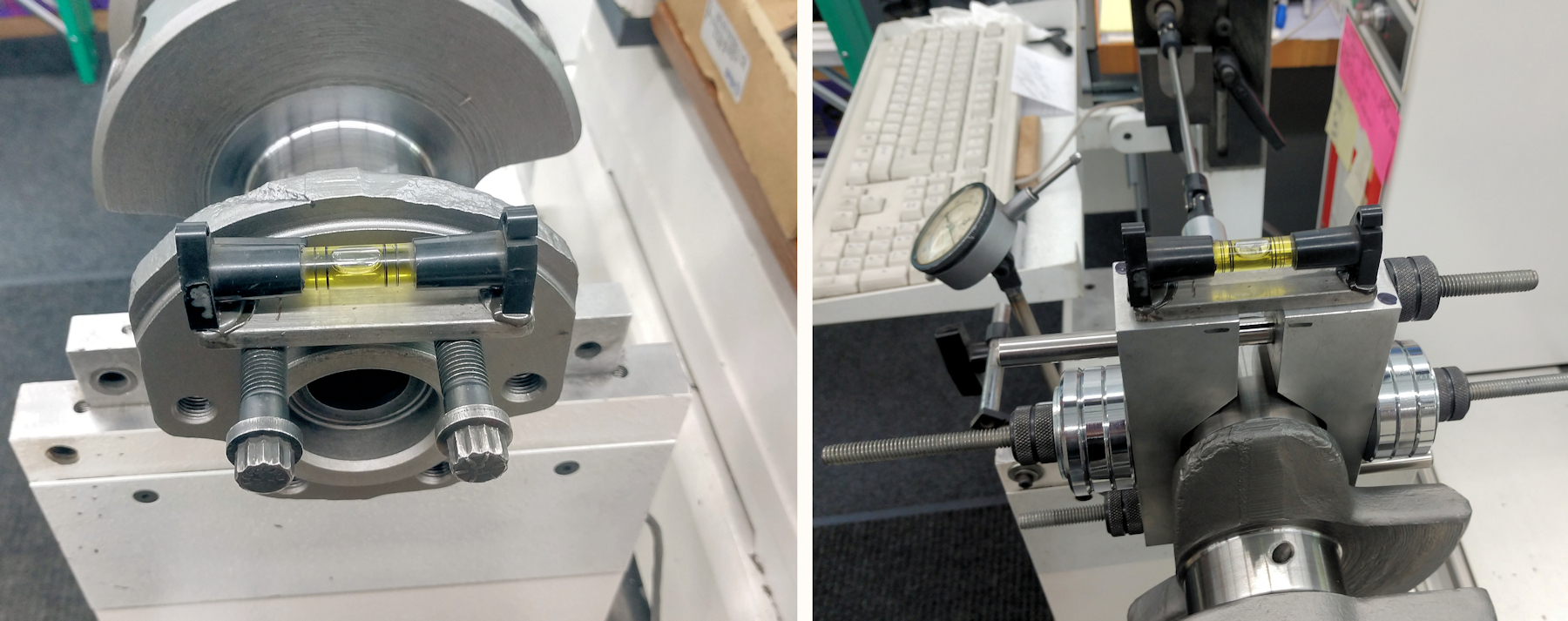

BOBWEIGHT PLACEMENT I always “phase” my bobweights. I start by screwing in a couple bolts into the crankshaft flange. It seems to be a good starting place and seems to place the first throw up. I level across the bolts then 0 my degree wheel. Then I level each...

by Donnie Hurt | Aug 1, 2021 | OTHER SHOP WORK

CRANK ROTATING STUB I needed a tool for rotating the crankshaft when adjusting valves, and the harmonic balancer was on the engine. I cut off the snout end of an old crankshaft. With the woodruff key or keys installed, I put it into the end of the balancer and then...

by Donnie Hurt | Aug 1, 2021 | OTHER SHOP WORK

BROKEN TAP OR EZ-OUT If you have broken a tap or easy-out, how do you drill it? Go to the hardware store and buy a few cheap masonry drills. The type with a spade piece of carbide in the end. These drills will put up with lots of abuse and you can drill a hole in a...