by Donnie Hurt | May 1, 2021 | OTHER SHOP WORK

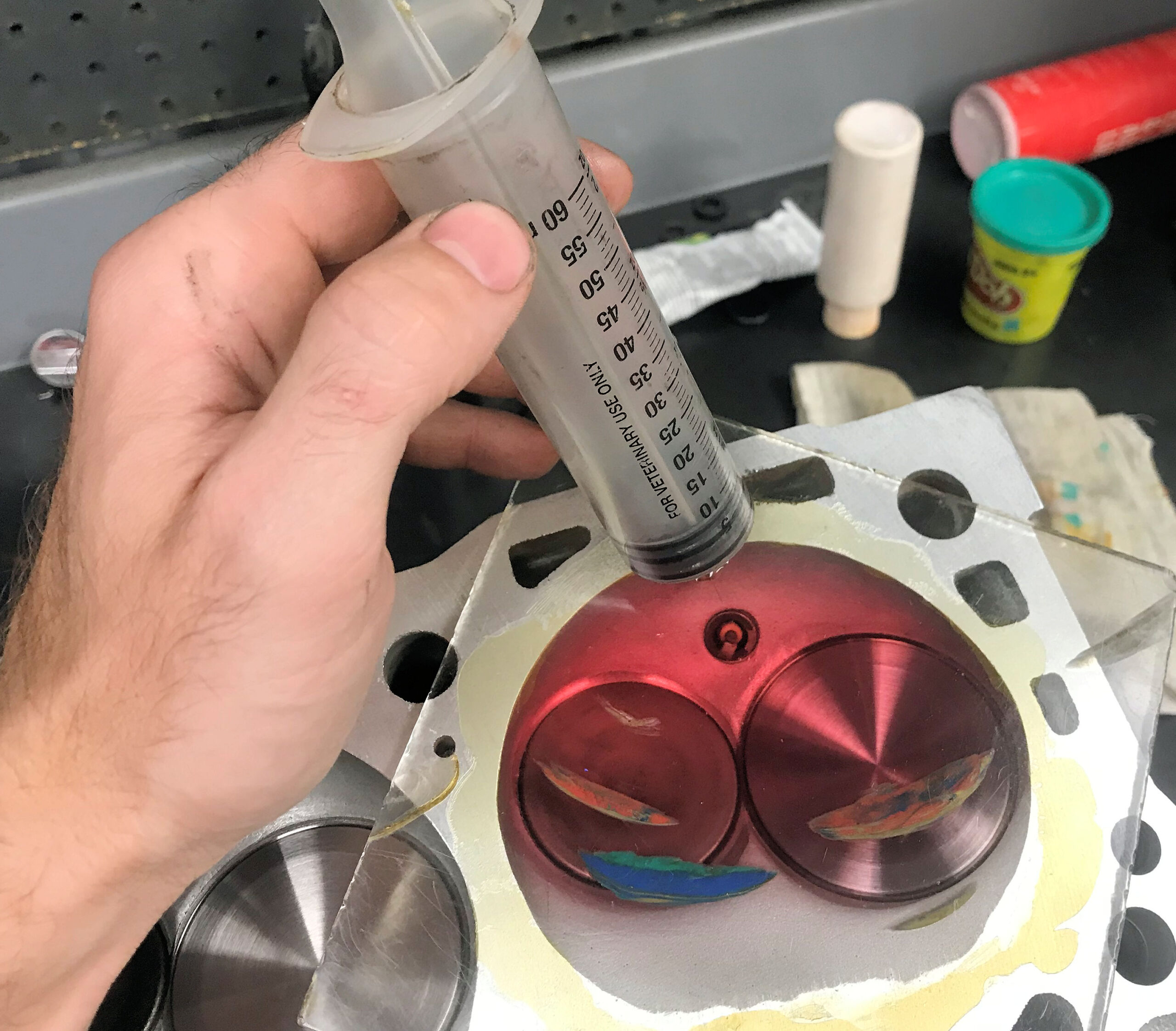

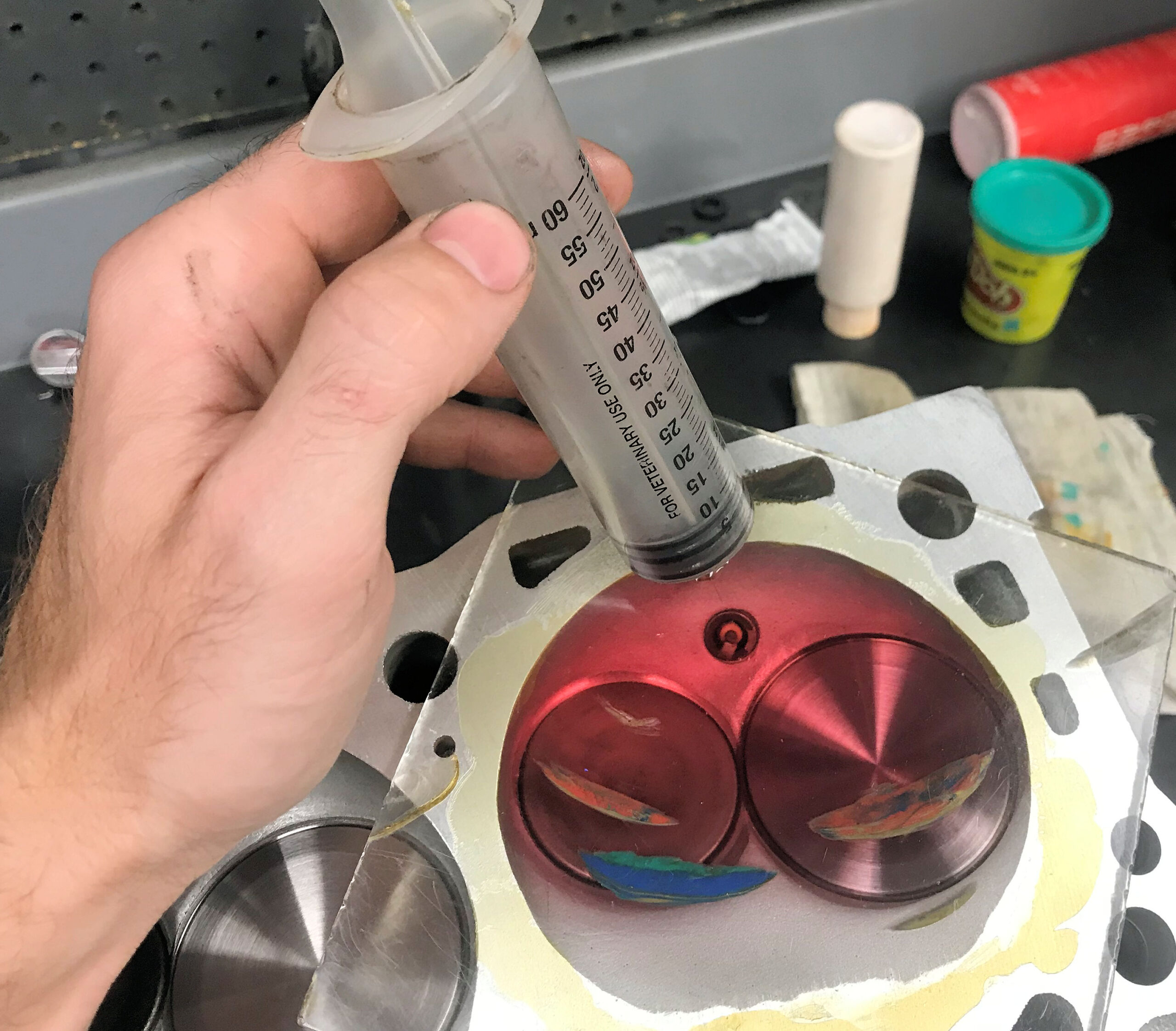

SUCK IT UP When performing volume checks, this cuts down on the mess to clean up afterwards. Once finished pouring the volume, we use this syringe and a piece of tubing to suck the fluid out of the cylinder or chamber before removing the plate. The syringes can be...

by Donnie Hurt | May 1, 2021 | CYLINDER HEADS

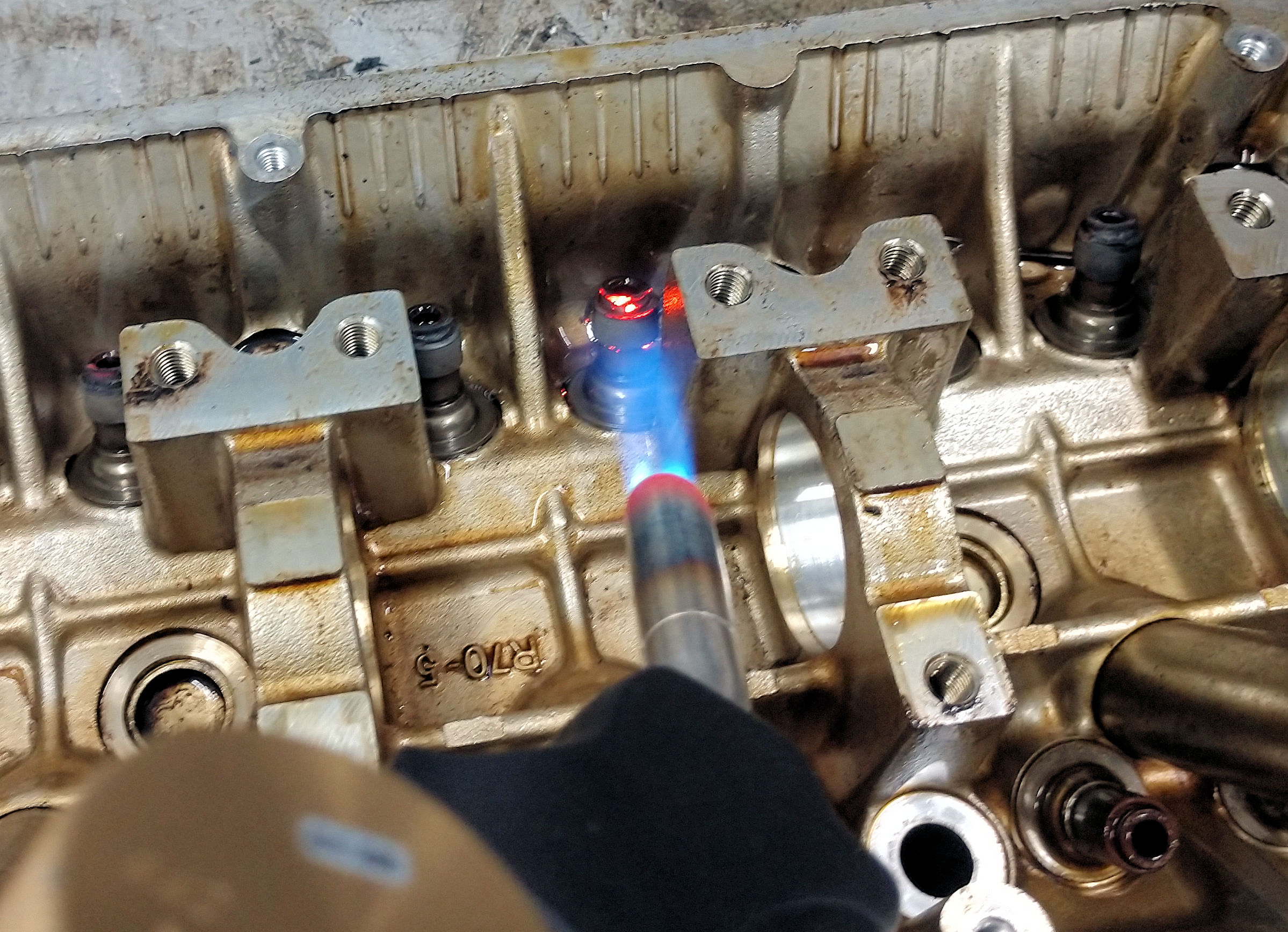

SEAT REPAIRS THAT DON’T LEAK When installing valve seats, you sometimes run across porosity that leads into water at the base of the counterbore. I like to pressure test after the counterbores are If you have a seat that you’re trying to seal up, you can make a...

by Donnie Hurt | Apr 1, 2021 | PISTONS & RINGS

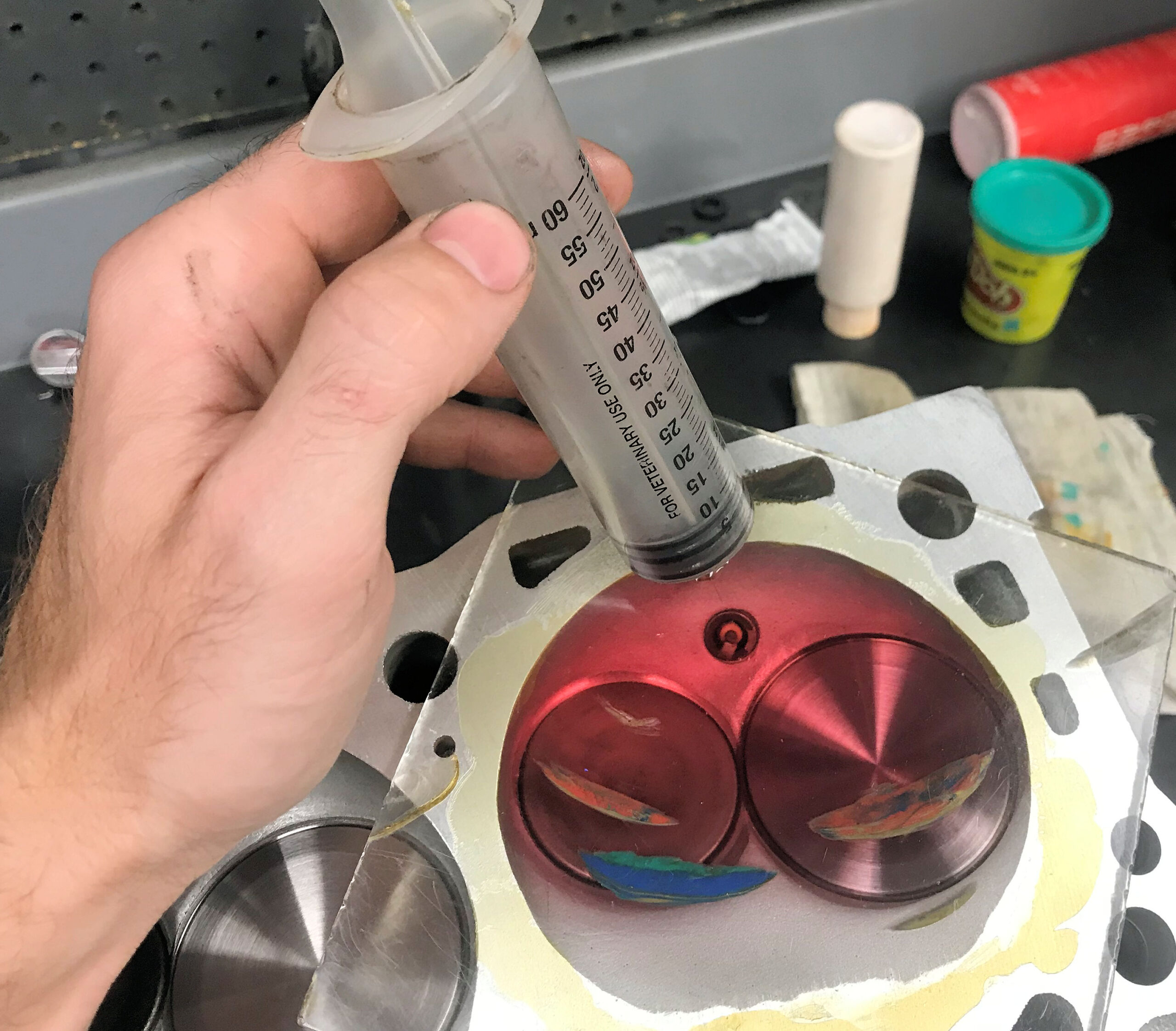

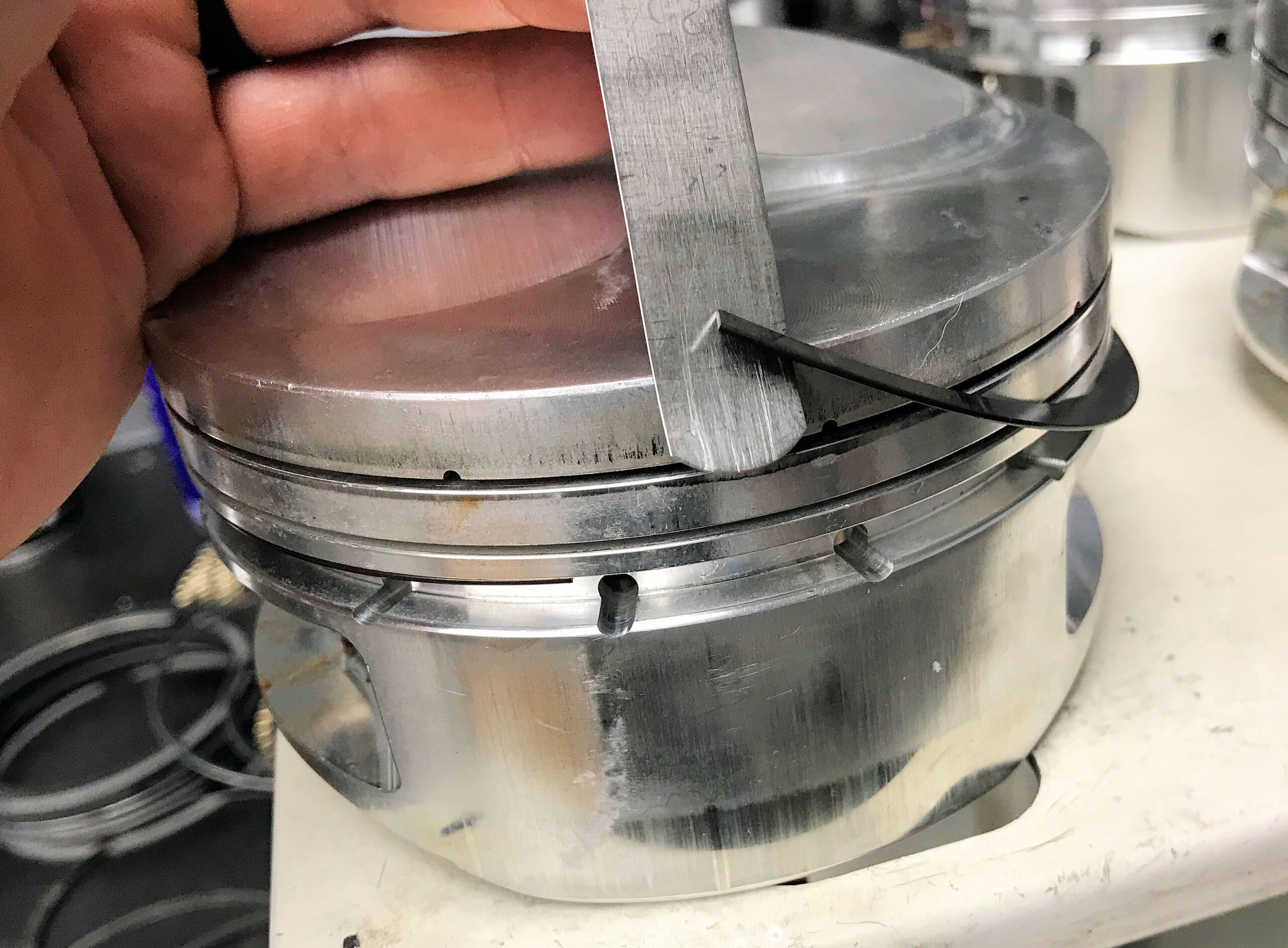

SUPPORT RAIL INSTALL When using pistons that require oil ring support rails, we use a .008” feeler gauge between the piston and the rail as we slide the rail into place. This way it does not scratch the piston or catch as its going into place. Adam Cofer Salina Engine...

by Donnie Hurt | Apr 1, 2021 | DISASSEMBLY & CLEANING

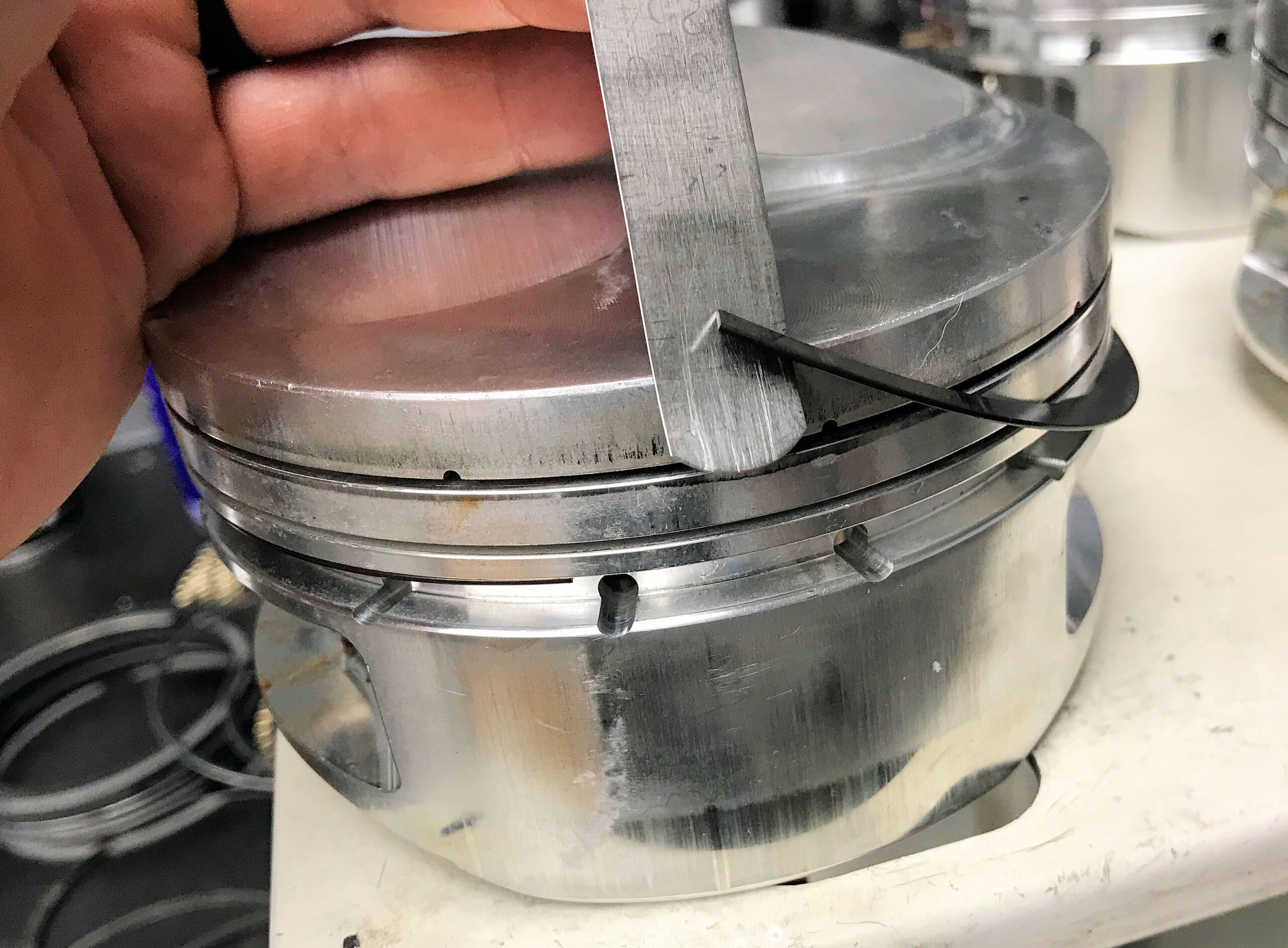

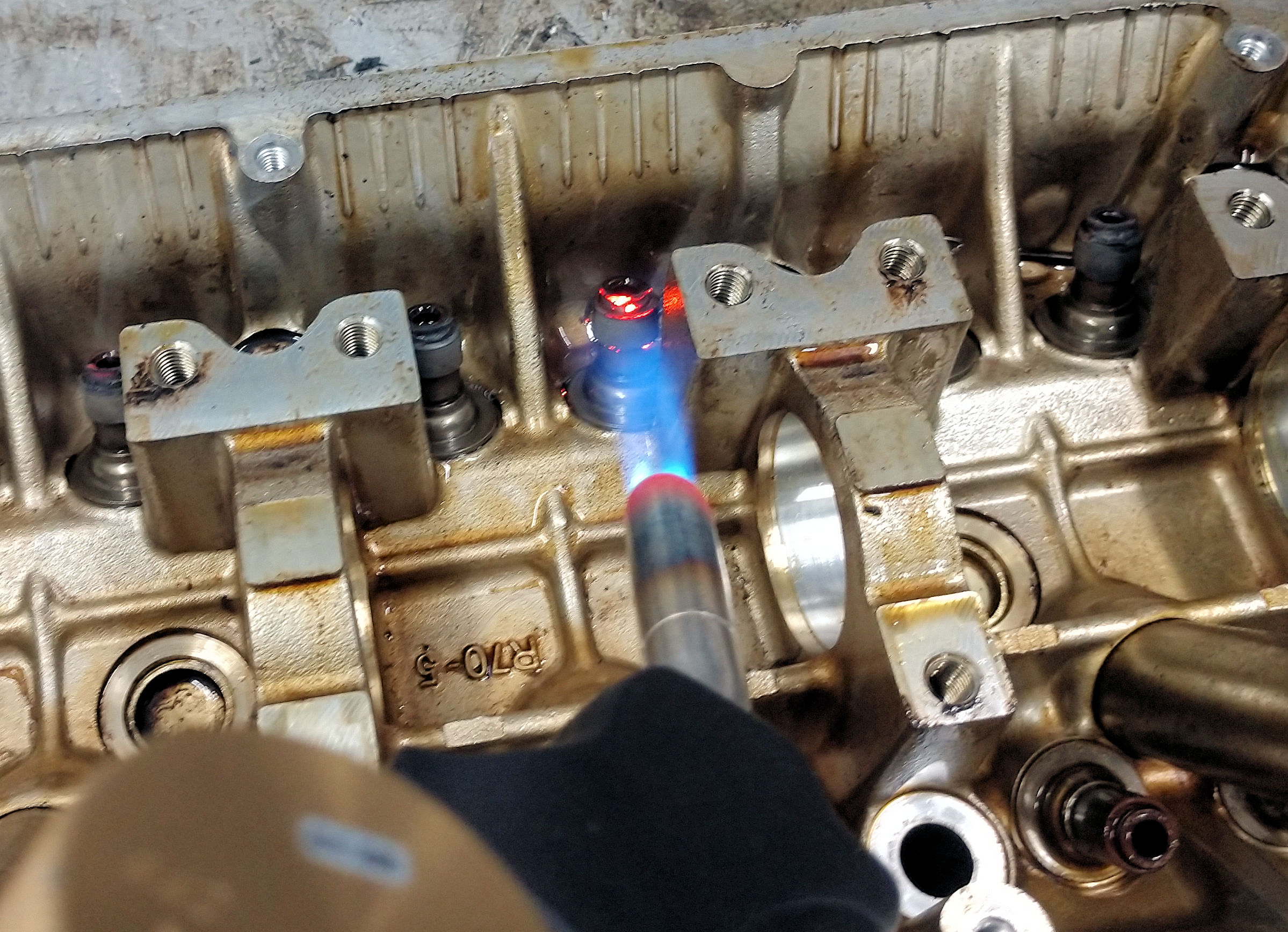

ANOTHER SILLY HEAT TRICK We all heat our oil plugs, studs and bolts to free them up. I found another heat solution, removing stubborn valve seals. I just warm them up with a propane torch to soften the rubber and they pull right off. This works great! Randy Torvinen...

by Donnie Hurt | Apr 1, 2021 | DISASSEMBLY & CLEANING

HEX HEAD VALVE NUT Disassembling an old stuck engine can be challenging. When valves are stuck in the valve guides, try welding a nut to the face of the valve. Now you can rotate it to help free it from the guide. Dave Matton D and D Auto Machine Bloomington, MN...